Efficient treatment resistance sheet type silencer

A muffler and resistive technology, applied in the field of resistive chip mufflers, can solve the problems of increased maintenance cost, poor effect, inconvenient disassembly and assembly of mufflers, etc., and achieve the effects of efficient management, good management and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

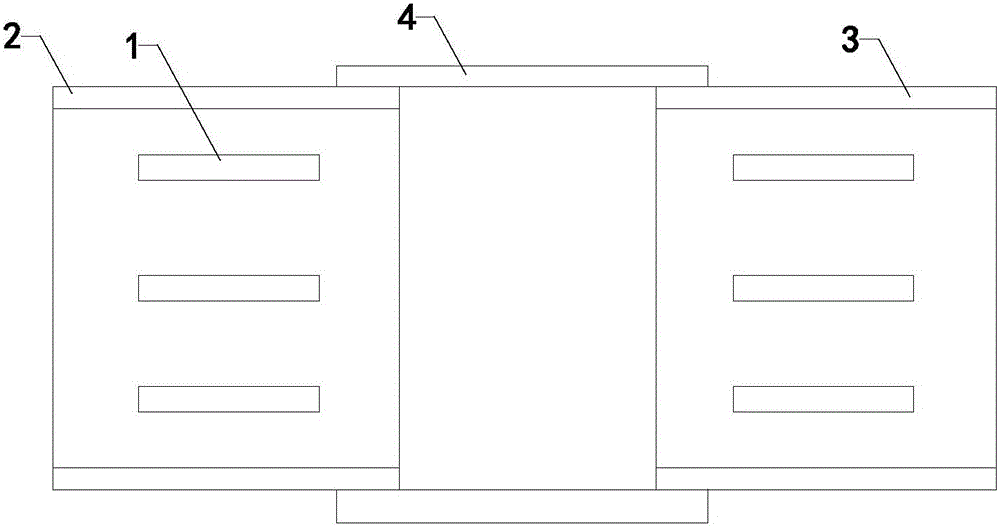

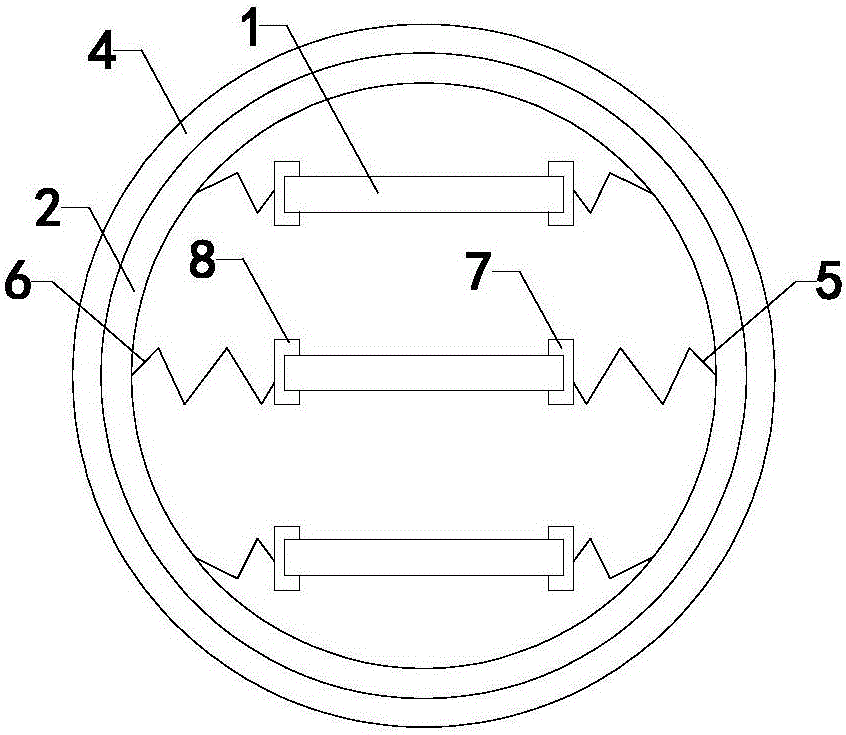

[0011] Such as figure 1 and figure 2 As shown, a kind of high-efficiency management of the present invention resistive plate muffler includes a shell and a sound-absorbing plate 1, and the shell includes a left split body 2, a right split body 3 and an adjusting pipe 4, the right end of the left split body and the right The left end of the split body is provided with an external thread structure, and the inner wall of the adjustment tube is provided with an internal thread structure. The right end of the left split body and the left end of the right split body are inserted and screwed into the inside of the adjustment tube; the left split body and the right split body T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com