Intelligent control driver for electric eddy speed damper and its control method

An eddy current retarder and intelligent control technology, applied in the control of electromechanical brakes, electric braking systems, electric vehicles, etc., can solve problems such as increased maintenance costs, uneven aging, and low contact life, and achieve improved service life. , The effect of uniform aging of coil and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

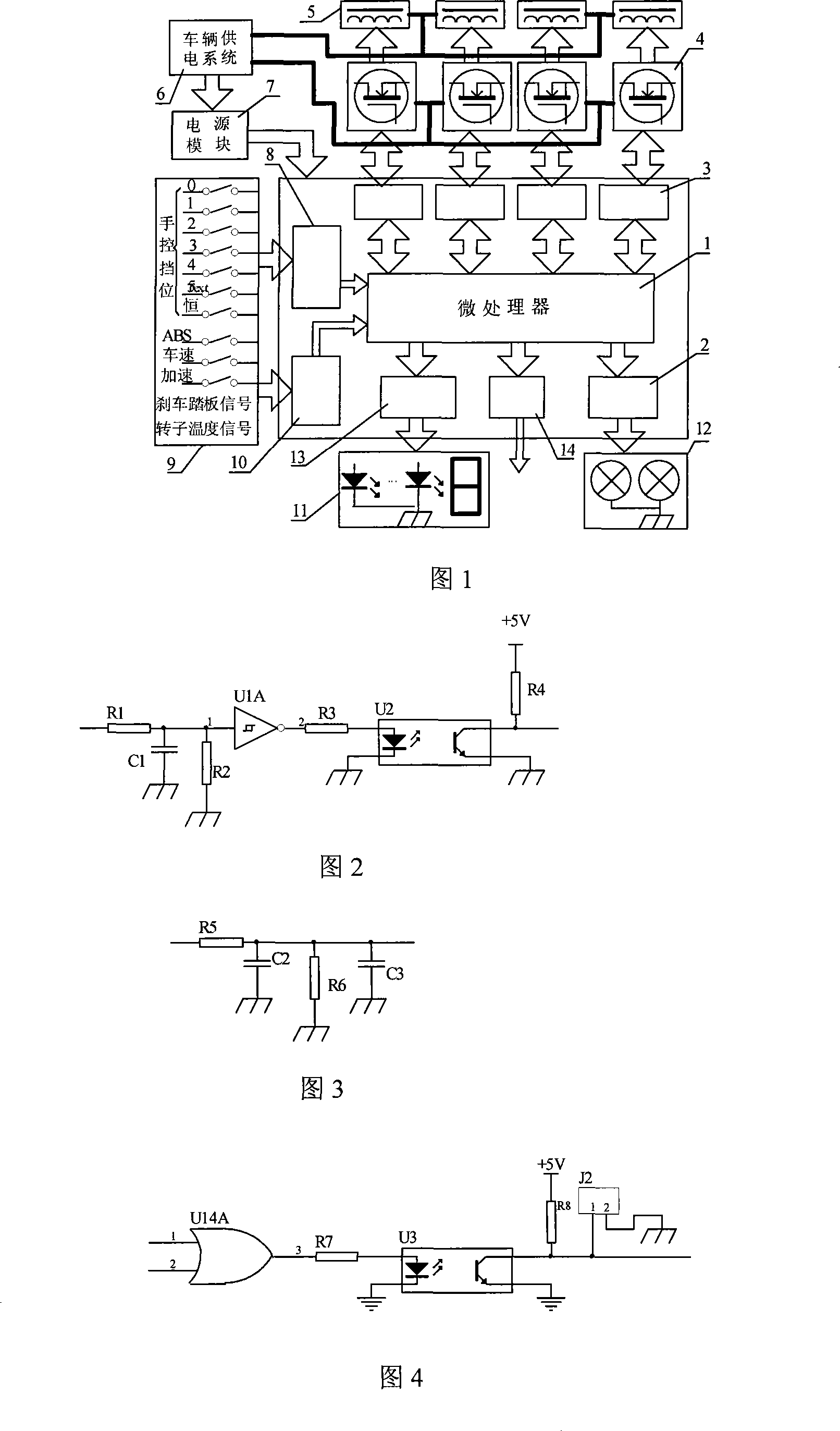

[0024] As shown in Figure 1, the present invention selects mixed-signal system-level single-chip microcomputer C8051F020 as microprocessor 1, and vehicle power supply system 6 supplies power to each group of excitation coils 5 and power supply module 7, and several switch signal detection circuits 8 and analog signal detection circuits 10 , non-contact intelligent power device 4, intelligent power device drive circuit and overcurrent / short circuit protection circuit 3, gear / fault / accelerator pedal error operation indication circuit 11 and its drive circuit 13, accelerator pedal redundant error command output circuit 14, Brake lamp driving circuit 2 is connected to microprocessor 1 through I / O ports; each group of exciting coils 5 is connected to non-contact intelligent power device 4 . The detection circuit 9 includes a switch signal detection circuit 8 and an analog signal detection circuit 10. The switch signals detected by the switch signal detection circuit 8 include 7 manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com