Cellulose fiber, preparation method thereof and equipment

A technology of cellulose fibers and manufacturing methods, which is applied in the field of chemical fibers and can solve problems such as poor mechanical properties of fibers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] In a 1.5L conical bottom kettle, add 940 grams of 7.5wt% NaOH / 14wt% urea mixed aqueous solution, cool it to -6°C, then add 60 grams of cotton pulp (polymerization degree 500) and stir rapidly until the solution is clear and transparent.

[0088] The required spinning solution was obtained by removing air bubbles in the solution under reduced pressure, and nitrogen gas was injected into the kettle to 0.5MPa, and the valve at the bottom of the kettle, the gear metering pump and the temperature control system of the solution were opened, so that the spinning temperature was 25°C. The silk liquid is extruded from a spinneret with 0.07mm×1000 holes at a speed of 25m / min.

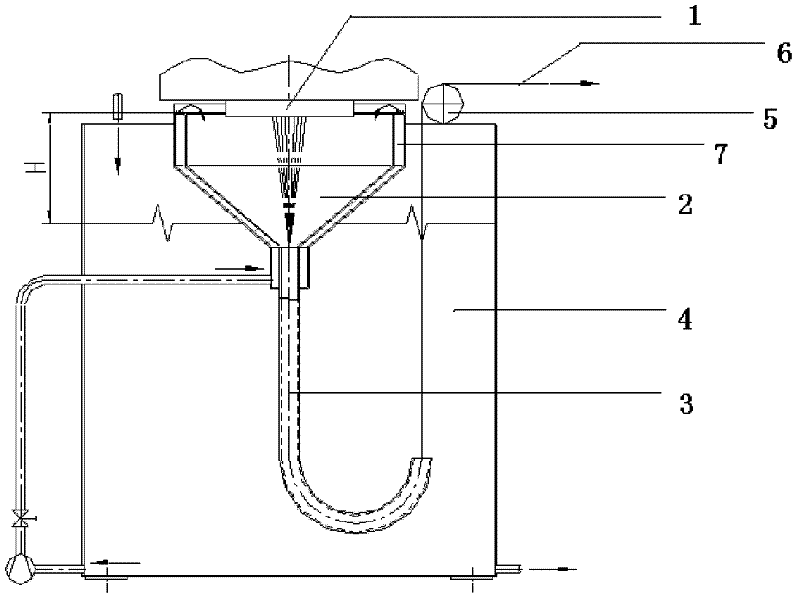

[0089] Place the spinneret on the attached figure 1 In the coagulation liquid downstream drafting device shown, the speed of the first godet roller at the rear end of the coagulation liquid downstream drafting device is set to 75m / min, and when the liquid level difference between the funnel and the coagula...

Embodiment 2

[0096] In a 1.5L conical bottom kettle, add 920 grams of 10wt% NaOH / 11.5wt% urea mixed aqueous solution, cool it to -7°C, then add 80 grams of wood pulp (polymerization degree 550) and stir rapidly until the solution is clear and transparent.

[0097] After removing air bubbles in the solution under reduced pressure, the required spinning solution was obtained, and nitrogen gas was injected into the kettle to 1.0 MPa, and the valve at the bottom of the kettle, the gear metering pump and the temperature control system of the solution were opened, so that the spinning temperature was 17°C. The spinning solution was extruded from a spinneret with 0.1 mm×500 holes at a speed of 25 m / min.

[0098] Place the spinneret on the attached figure 1 In the coagulation liquid downstream drafting device shown, the speed of the first godet roller at the rear end of the coagulation liquid downstream drafting device is set to 125m / min, and when the liquid level difference between the funnel and...

Embodiment 3

[0105] In a 1.5L conical bottom kettle, add 900 grams of 10.5wt% NaOH / 11.5wt% urea mixed aqueous solution, cool it to -8°C, then add 100 grams of wood pulp (polymerization degree 550) and stir quickly until the solution is clear and transparent .

[0106] The required spinning solution was obtained by removing air bubbles in the solution under reduced pressure, and nitrogen gas was injected into the kettle to 1.5MPa, and the valve at the bottom of the kettle, the gear metering pump and the temperature control system of the solution were opened, so that the spinning temperature was 10°C. The spinning solution was extruded from a spinneret with 0.1 mm×500 holes at a speed of 15 m / min.

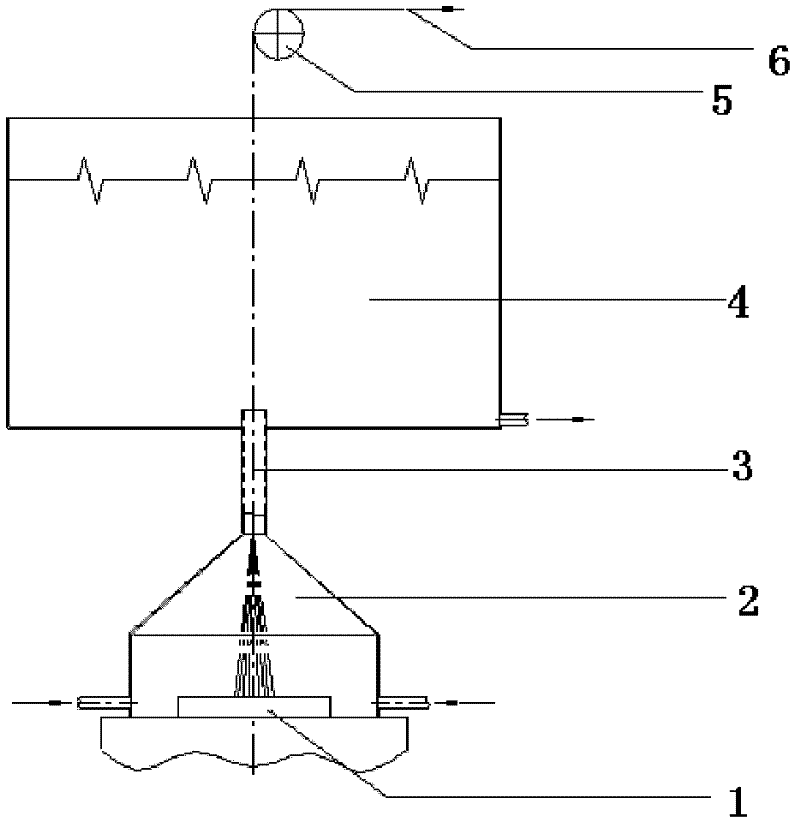

[0107] Place the spinneret on the attached figure 2 In the coagulation liquid downstream drafting device shown, the diameter of the circular tube is 20mm. Set the speed of the first godet roller at the rear end of the coagulation liquid downstream drafting device to 105m / min, and adjust the flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com