Method for preparing inoculant for refining as-cast structure of spring steel and application method thereof

A technology of as-cast structure and application method, which is applied in the field of alloy steel, can solve the problems of unsatisfactory grain and structure refinement effect of spring steel, insufficient dispersion of carbide particles, and insufficient mechanical properties of spring steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Step One, Ingredients

[0045] The required iron, vanadium, niobium and aluminum raw materials are weighed according to the molar ratio of Fe:V:Nb:Al=3.2:0.5:1.9:1.5.

[0046] The second step, melting

[0047] Mix the iron, vanadium, niobium and aluminum raw materials weighed in the first step into a vacuum melting furnace, make them melt and mix well and solidify into a FeVNbAl master alloy block;

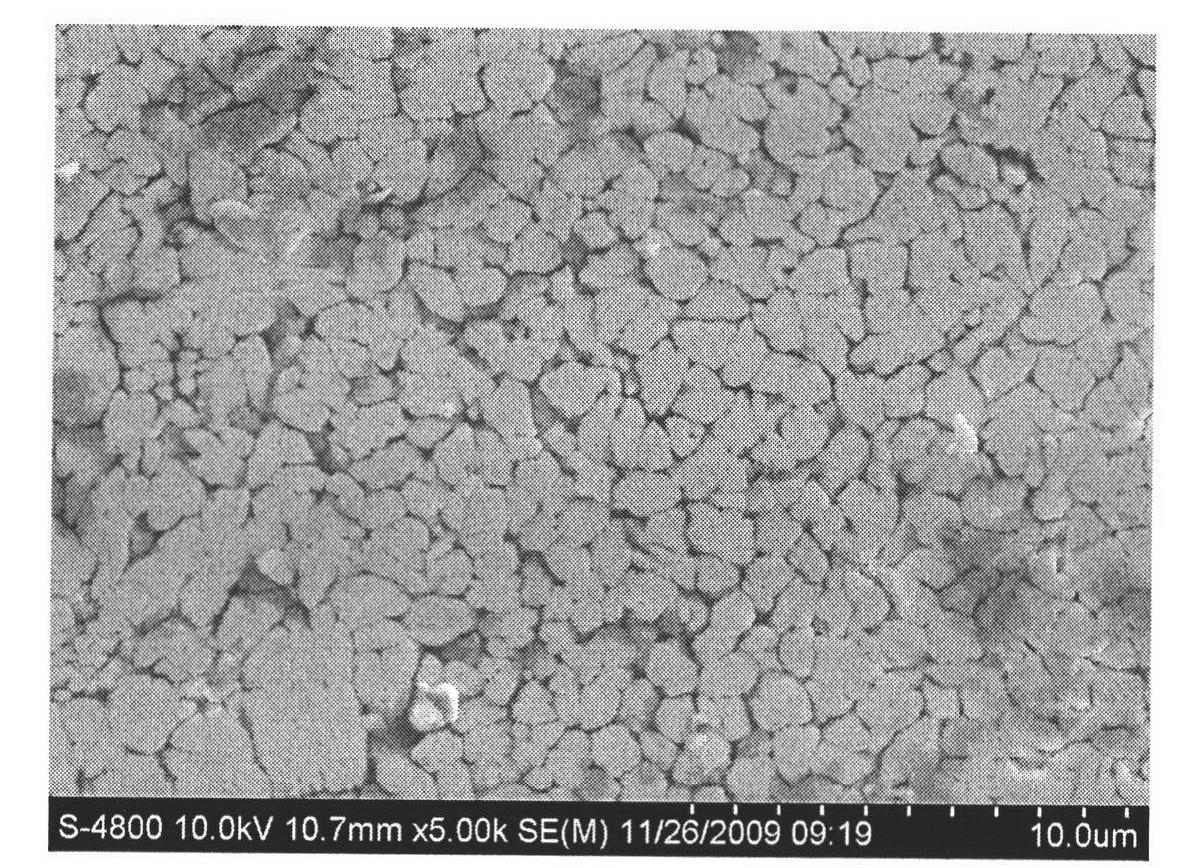

[0048] The third step, centrifugal quick quenching

[0049] Weigh the required amount of FeVNbAl intermediate alloy blocks obtained in the second step, break them into small pieces, put them into the water-cooled copper crucible of the vacuum quenching furnace, and adjust the electrode position so that it is in the middle of the FeVNbAl in the crucible. The distance between the small alloy pieces is 0.5mm, close the furnace door, inlet and outlet and air release valve of the vacuum quenching furnace, and vacuumize until the vacuum pressure is higher than 5×10 -3 After Pa...

Embodiment 2

[0051] Step One, Ingredients

[0052] The required iron, vanadium, niobium and aluminum raw materials are weighed according to the molar ratio of Fe:V:Nb:Al=4.4:1.0:3.1:2.5.

[0053] The second step, melting

[0054] Mix the iron, vanadium, niobium and aluminum raw materials weighed in the first step into a vacuum melting furnace, make them melt and mix well and solidify into a FeVNbAl master alloy block;

[0055] The third step, centrifugal quick quenching

[0056] Weigh the required amount of FeVNbAl intermediate alloy blocks obtained in the second step, break them into small pieces, put them into the water-cooled copper crucible of the vacuum quenching furnace, and adjust the electrode position so that it is in the middle of the FeVNbAl in the crucible. The distance between the small alloy pieces is 1.0mm, close the furnace door, inlet and outlet and air release valve of the vacuum quenching furnace, and vacuumize until the vacuum pressure is higher than 5×10 -3 After Pa...

Embodiment 3

[0058] Step One, Ingredients

[0059] The required iron, vanadium, niobium and aluminum raw materials are weighed according to the molar ratio of Fe:V:Nb:Al=5.6:1.5:4.3:3.5.

[0060] The second step, melting

[0061] Mix the iron, vanadium, niobium and aluminum raw materials weighed in the first step into a vacuum melting furnace, make them melt and mix well and solidify into a FeVNbAl master alloy block;

[0062] The third step, centrifugal quick quenching

[0063] Weigh the required amount of FeVNbAl intermediate alloy blocks obtained in the second step, break them into small pieces, put them into the water-cooled copper crucible of the vacuum quenching furnace, and adjust the electrode position so that it is in the middle of the FeVNbAl in the crucible. The distance between the small alloy pieces is 1.5mm, close the furnace door, inlet and outlet and air release valve of the vacuum quick quenching furnace, and vacuumize until the vacuum pressure is higher than 5×10 -3 Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com