Preparation and application method of inoculant for tissue deterioration refinement of high-speed steel for roller

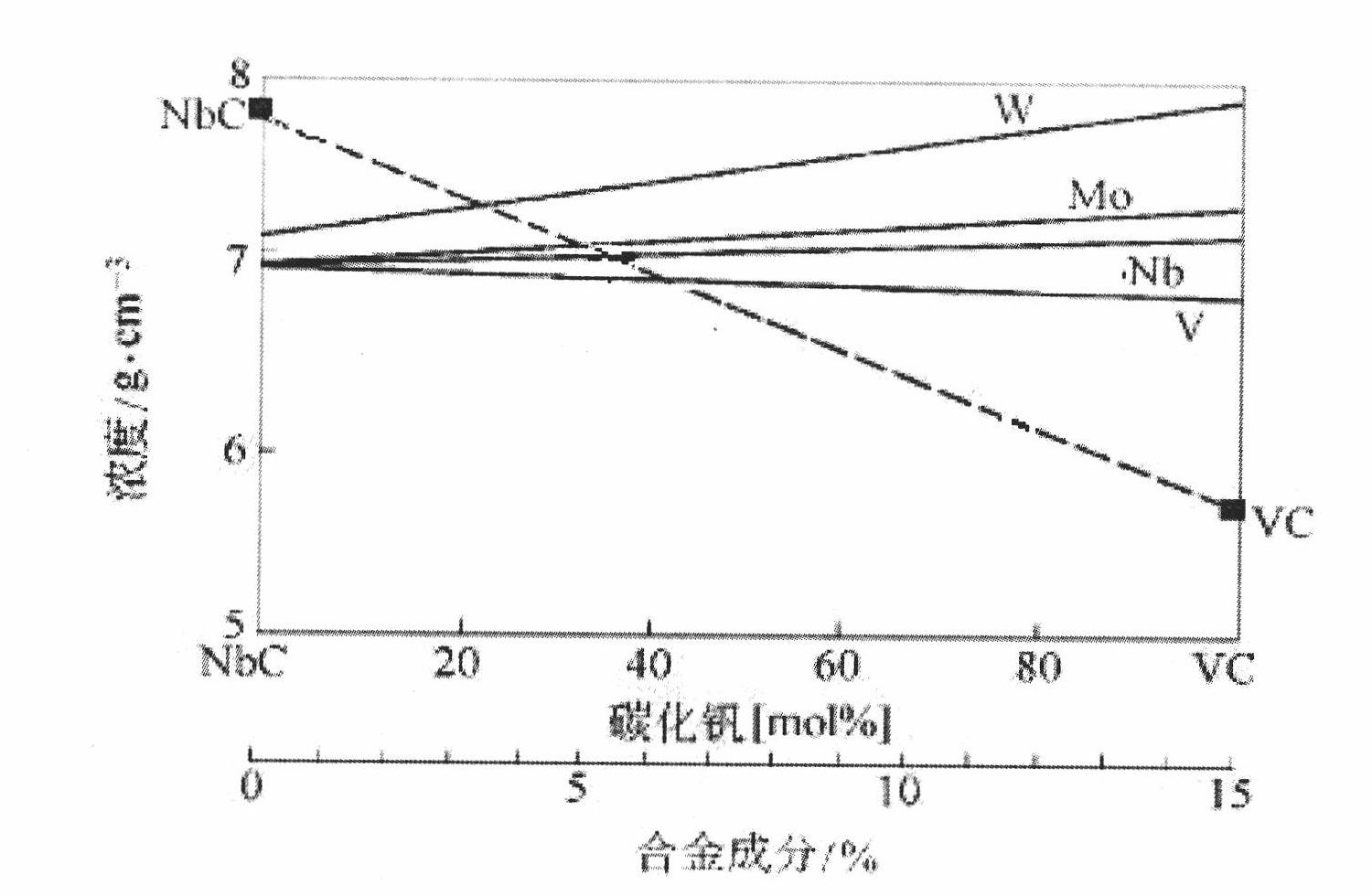

A technology of metamorphic refinement and high-speed steel, which is applied in the field of metal casting technology, can solve the problems of inconspicuousness, coarse grain, unsatisfactory effect of grain and structure refinement of high-speed steel alloy matrix for rolls, etc., to avoid specific gravity segregation, The effect of improving the comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

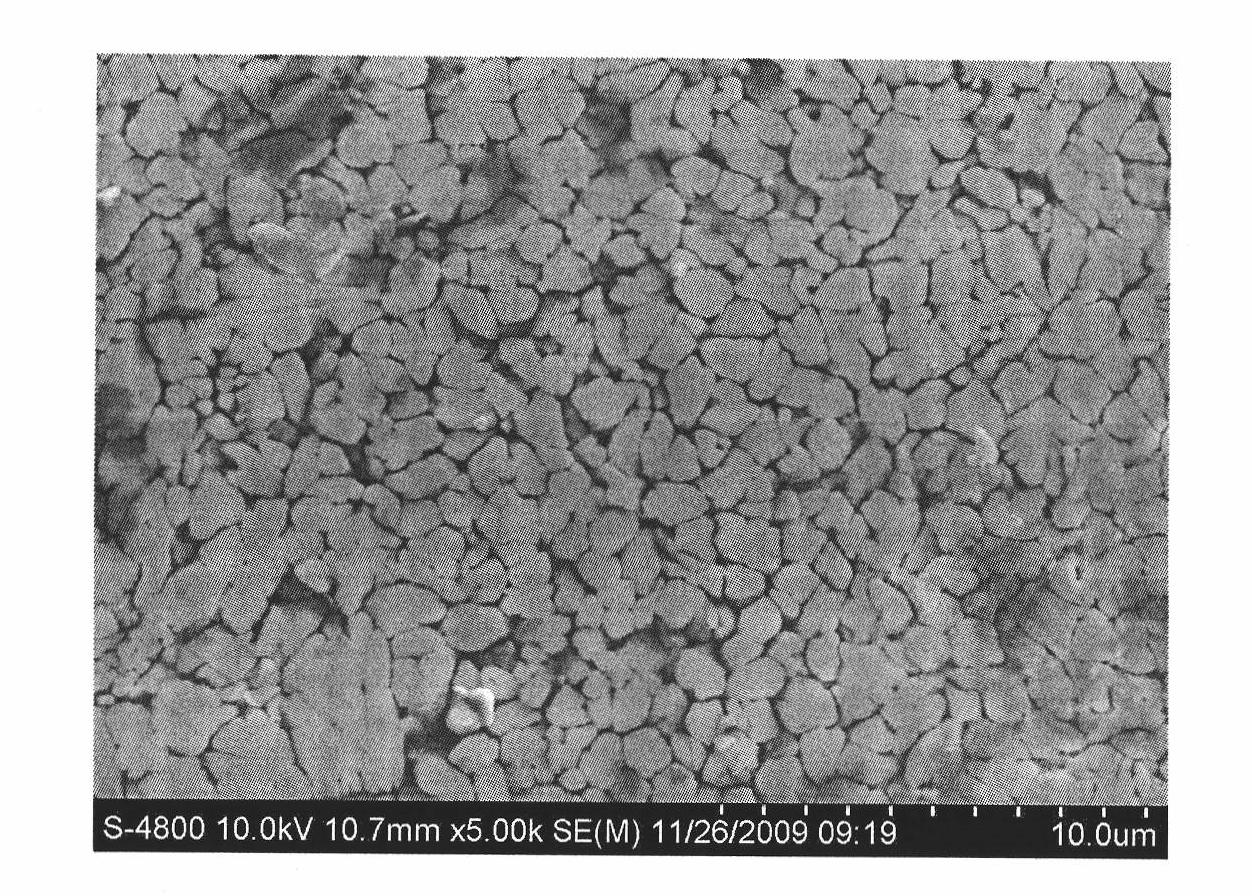

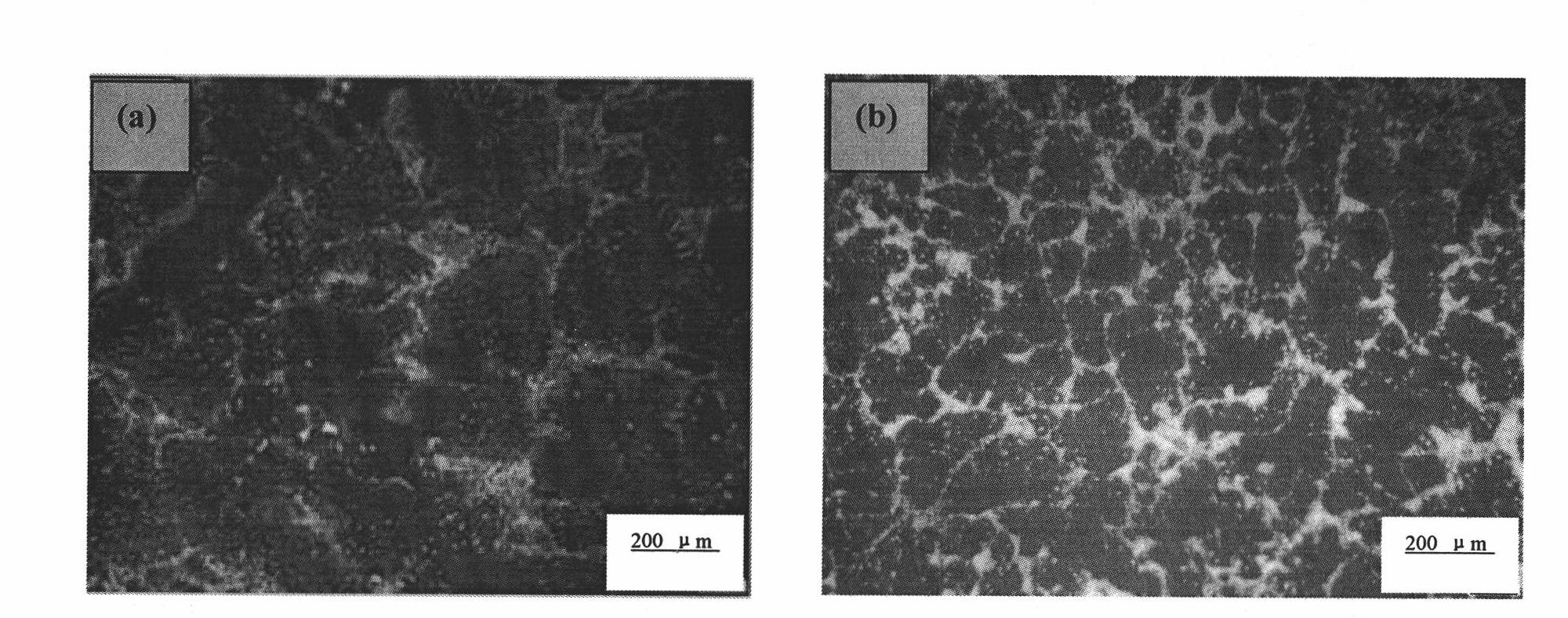

Examples

Embodiment 1

[0068] The preparation method of the inoculant used for the modification and refinement of the high-speed steel structure for the roll adopts the rapid quenching strip method, and the steps are as follows:

[0069] Step One, Ingredients

[0070] Ferroniobium, ferro-vanadium master alloy and pig iron from the foundry raw material market are used as raw materials, wherein the composition of ferroniobium master alloy is 65% niobium and 35% iron by mass percentage, and the composition of ferro-vanadium master alloy is 49% vanadium and 51% by mass % iron, according to the set mass ratio Fe: V: Nb=5.6: 1.9: 1.5, weigh the required ferro-niobium, ferro-vanadium and pig iron;

[0071] The second step, melting

[0072] Mix the ferroniobium, ferrovanadium and pig iron weighed in the first step into a vacuum melting furnace, make them fully mixed evenly after melting and solidify into a FeVNb master alloy block;

[0073] The third step, centrifugal quick quenching

[0074] Weigh the r...

Embodiment 2

[0076] The preparation method of the inoculant used for the modification and refinement of the high-speed steel structure for the roll adopts the rapid quenching strip method, and the steps are as follows:

[0077] Step One, Ingredients

[0078]Ferroniobium, ferro-vanadium master alloy and pig iron from the casting raw material market are used as raw materials, wherein the composition of ferroniobium master alloy is 68% niobium and 32% iron by mass percentage, and the composition of ferro-vanadium master alloy is 51% vanadium and 49% by mass % iron, according to the set mass ratio Fe: V: Nb = 4.4: 3.1: 2.5, weigh the required ferro-niobium, ferro-vanadium and pig iron;

[0079] The second step, melting

[0080] Mix the ferroniobium, ferrovanadium and pig iron weighed in the first step into a vacuum melting furnace, make them fully mixed evenly after melting and solidify into a FeVNb master alloy block;

[0081] The third step, centrifugal quick quenching

[0082] Weigh the ...

Embodiment 3

[0084] The preparation method of the inoculant used for the modification and refinement of the high-speed steel structure for the roll adopts the rapid quenching strip method, and the steps are as follows:

[0085] Step One, Ingredients

[0086] Ferroniobium, ferro-vanadium master alloy and pig iron from the casting raw material market are used as raw materials, wherein the composition of ferroniobium master alloy is 70% niobium and 30% iron by mass percentage, and the composition of ferro-vanadium master alloy is 53% vanadium and 47% by mass % iron, according to the set mass ratio Fe: V: Nb=3.2: 4.3: 3.5, weigh the required ferro-niobium, ferro-vanadium and pig iron;

[0087] The second step, melting

[0088] Mix the ferroniobium, ferrovanadium and pig iron weighed in the first step into a vacuum melting furnace, make them fully mixed evenly after melting and solidify into a FeVNb master alloy block;

[0089] The third step, centrifugal quick quenching

[0090] Weigh the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com