B2 phase toughened non-crystal composite and preparation method thereof

A technology of amorphous composite materials and composite materials, applied in the field of B2 phase toughened amorphous composite materials and its preparation, can solve the problems of easy cracks, poor mechanical properties, poor bonding force between the second phase and the amorphous matrix, etc. problems, achieve large elastic limit, excellent mechanical properties, and improve the effect of structural applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

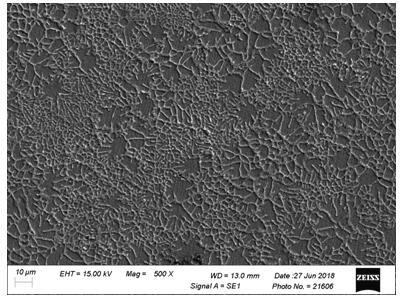

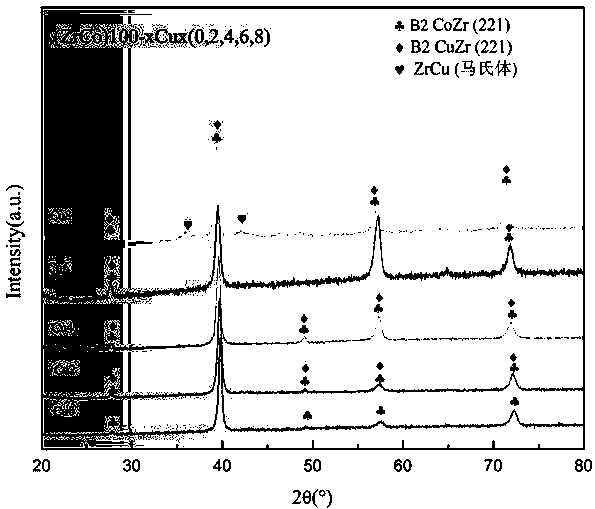

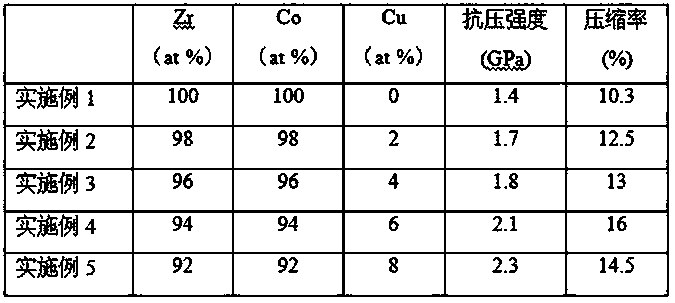

[0015] The B2 phase toughens the amorphous composite material, and the atomic ratio of the composite material is (ZrCo) 100 Cu 0 .

[0016] The preparation method of the B2 phase toughened amorphous composite material, its specific steps are as follows:

[0017] Will follow (ZrCo) 100 Cu 0 For batching, put the component metals (Zr, Co, Cu with a purity greater than 99.99%) in an electric arc melting furnace for melting. During the melting process, pump to a vacuum of 5×10 -5 Pa, then fill Ar gas with a purity of 99.9999% to an atmospheric pressure, heat the arc melting furnace until the temperature is above the melting point of the alloy (1890°C) and melt evenly, then the alloy is rapidly cooled to room temperature at a cooling rate of 1000K / s, and then the alloy is The ingot is turned over, remelted, and repeated 4 times to obtain the master alloy. After the master alloy is remelted, it is suction-cast into a block through a copper mold (ZrCo) 100 Cu 0 Amorphous compos...

Embodiment 2

[0020] The B2 phase toughens the amorphous composite material, and the atomic ratio of the composite material is (ZrCo) 98 Cu 2 .

[0021] The preparation method of the B2 phase toughened amorphous composite material, its specific steps are as follows:

[0022] Will follow (ZrCo) 98 Cu 2 For batching, put the component metals (Zr, Co, Cu with a purity greater than 99.99%) in an electric arc melting furnace for melting. During the melting process, pump to a vacuum of 5×10 -5 Pa, and then fill Ar gas with a purity of 99.9999% to an atmospheric pressure, heat the arc melting furnace to a temperature above the melting point of the alloy (1890°C) and melt evenly, then the alloy is rapidly cooled to room temperature at a cooling rate of 1000 K / s, and then The alloy ingot is turned over, remelted, and repeated 5 times to obtain the master alloy. After the master alloy is remelted, it is suction-cast into a block through a copper mold (ZrCo) 98 Cu 2 Amorphous composite material ...

Embodiment 3

[0025] The B2 phase toughens the amorphous composite material, and the atomic ratio of the composite material is (ZrCo) 96 Cu 4 .

[0026] The preparation method of the B2 phase toughened amorphous composite material, its specific steps are as follows:

[0027] Will follow (ZrCo) 96 Cu 4 For batching, put the component metals (Zr, Co, Cu with a purity greater than 99.99%) in an electric arc melting furnace for melting. During the melting process, pump to a vacuum of 5×10 -5 Pa, then fill Ar gas with a purity of 99.9999% to an atmospheric pressure, heat the arc melting furnace until the temperature is above the melting point of the alloy (1890°C) and melt evenly, then the alloy is rapidly cooled to room temperature at a cooling rate of 1000K / s, and then the alloy is The ingot is turned over, remelted, and repeated 10 times to obtain the master alloy. After the master alloy is remelted, it is suction-cast into a block through a copper mold (ZrCo) 96 Cu 4 Amorphous composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com