Heat treatment device and heat treatment method

A heat treatment method and a technology for processed objects, which are applied in heat treatment equipment, heat treatment process control, quenching devices, etc., can solve problems such as deformation, poor quality, and differences in cooling characteristics of processed objects, and achieve suppression of uneven temperature distribution and avoid deformation and the effect of hardness deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

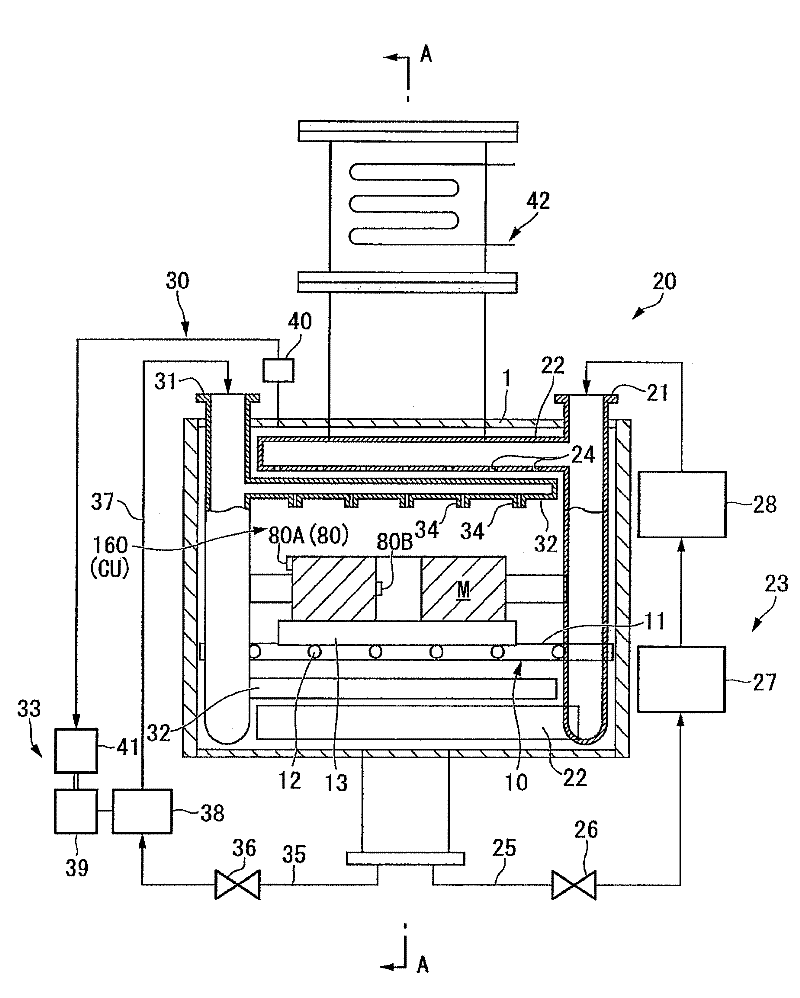

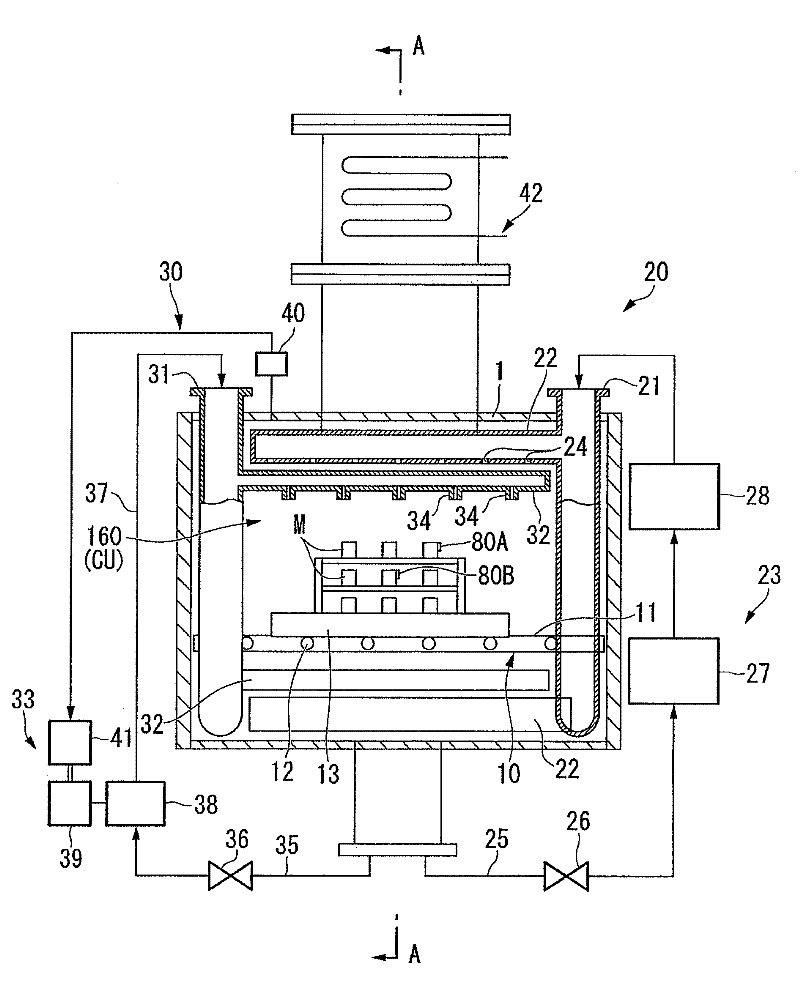

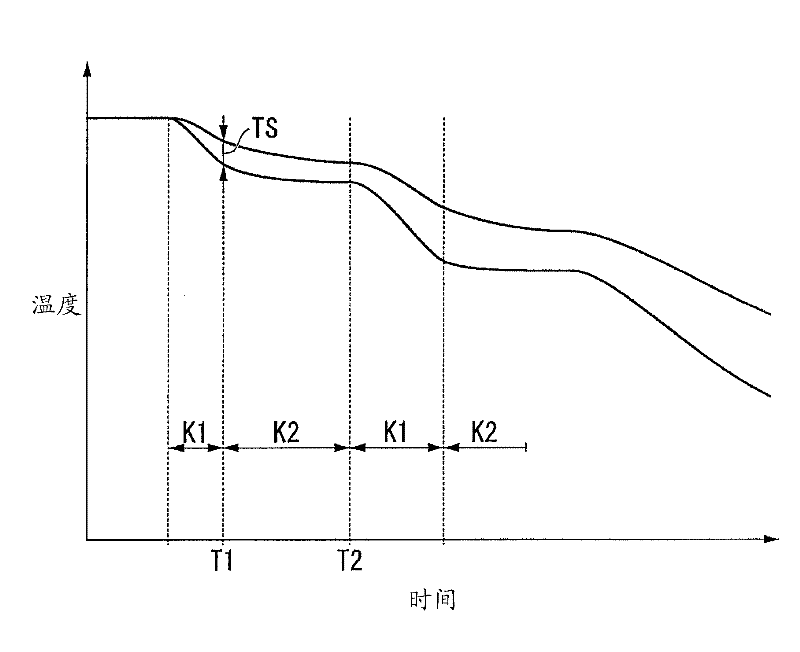

[0034] Refer to the following Figure 1 to Figure 6 Embodiments of the heat treatment apparatus and the heat treatment method of the present invention will be described.

[0035] In addition, in each drawing used in the following description, the scale of each member is suitably changed in order to make each member a recognizable size.

[0036] In addition, in the present embodiment, an example of a multi-chamber vacuum heat treatment furnace (hereinafter simply referred to as “vacuum heat treatment furnace”) is shown as the heat treatment apparatus.

[0037] figure 1 It is an overall configuration diagram of the vacuum heat treatment furnace of this embodiment.

[0038] The vacuum heat treatment furnace (heat treatment device) 100 is a device for performing heat treatment on the object to be processed, and is arranged adjacently in sequence with a degassing chamber 110, a preheating chamber 120, a carburizing chamber 130, a diffusion chamber 140, a cooling chamber 150, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com