Method forming high-melting-point high temperature alloy part via multi-laser head multi-laser beam path scanning

A high-temperature alloy and laser beam technology is applied in the field of scanning and forming high-melting superalloy parts with multiple laser heads and multiple laser beam paths. , Conducive to forming efficiency and forming accuracy, and the effect of strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred embodiments according to the present invention are now described in detail to further illustrate the present invention.

[0023] First of all, the CAD model of the part is designed using three-dimensional modeling software in the computer, and then the CAD model of the part is generated by the slice processing software and the multi-layer slice information is saved as an STL file. The data is transmitted to the computer of the powder spreading system in the selective laser melting rapid prototyping system; in the selective laser melting rapid prototyping system, the powder spreading system lays a layer of about 0.05-0.2mm thickness on the working platform High melting point and high temperature metal powder to be processed.

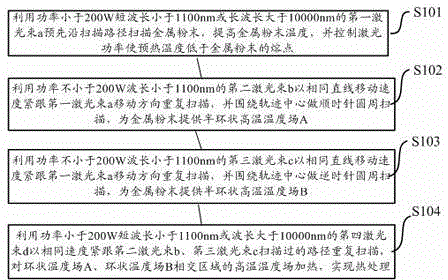

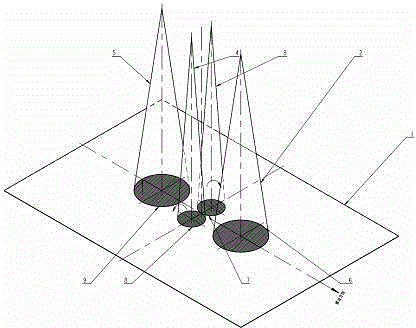

[0024] Such as figure 1 As shown, according to the multi-laser head and multi-laser beam path scanning method for forming high melting point superalloy parts of the present invention, in step S101, the power is less than 200W, the short wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com