Method for preparing precious metal gold particle catalytically-grown stannic oxide nanowire

A noble metal and tin oxide technology, applied in the field of catalysis, can solve problems such as unsatisfactory performance, and achieve the effects of no need for post-processing, high product purity, and simple equipment and technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

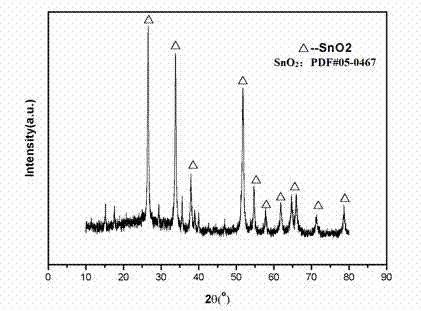

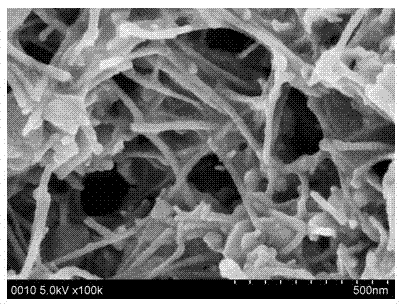

[0022] The precursor solution was formed by ultrasonically dissolving tin tetrachloride pentahydrate and chloroauric acid in absolute ethanol, in which the concentration of tin tetrachloride was 0.2 mol / l, and the molar ratio of Sn to Au was 100:1. The above-mentioned precursor solution is fed into the flame reaction zone with hydrogen / air as the auxiliary flame through a syringe pump and an atomizer at a feed rate of 4ml / min, and the hydrolysis reaction is carried out at a reaction temperature of 1800-2000°C. The total gas flow of hydrogen / air in the reaction flame is 1.8m 3 / h, the volume ratio of hydrogen / air is 1:5. The gaseous tin oxide generated by the hydrolysis reaction in the flame condenses and nucleates and grows along a certain direction under the induction and catalysis of the catalyst Au (VLS mechanism), and finally forms a tin oxide nanowire structure with noble metal gold particles at the tip. The nanowire has a diameter of 10-20 nm and a length of 0.2-0.5 μm....

Embodiment 2

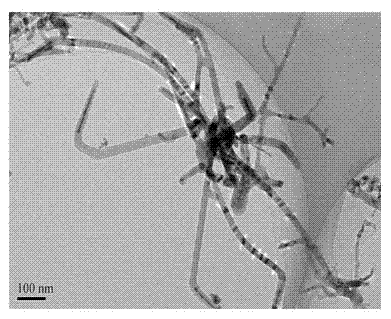

[0024] The precursor solution was formed by ultrasonically dissolving tin tetrachloride pentahydrate and chloroauric acid in absolute ethanol, in which the concentration of tin tetrachloride was 0.1 mol / l, and the molar ratio of Sn to Au was 50:1. The above-mentioned precursor solution is fed into the flame reaction zone with hydrogen / air as the auxiliary flame through a syringe pump and an atomizer at a feed rate of 4ml / min, and the hydrolysis reaction is carried out at a reaction temperature of 1600-1800°C. The total gas flow of hydrogen / air in the reaction flame is 1.2m 3 / h, the volume ratio of hydrogen / air is 1:3. The gaseous tin oxide produced by the hydrolysis reaction in the flame is induced and catalyzed by the catalyst Au, condenses and grows along a certain direction, and finally forms a tin oxide nanowire structure with noble metal gold particles at the tip. The diameter of the nanowire is 10-20nm, length 0.1-1μm. The TEM photograph of the product is as figure ...

Embodiment 3

[0026] The precursor solution was formed by ultrasonically dissolving tin tetrachloride pentahydrate and chloroauric acid in absolute ethanol, in which the concentration of tin tetrachloride was 0.2 mol / l, and the molar ratio of Sn to Au was 250:1. The above-mentioned precursor solution is fed into the flame reaction zone with hydrogen / air as the auxiliary flame through a syringe pump and an atomizer at a feed rate of 4ml / min, and the hydrolysis reaction is carried out at a reaction temperature of 1800-2000°C. The total gas flow of hydrogen / air in the reaction flame is 1.8m 3 / h, the volume ratio of hydrogen / air is 1:5. The gaseous tin oxide produced by the hydrolysis reaction in the flame is induced and catalyzed by the catalyst Au, condenses and grows along a certain direction, and finally forms a tin oxide nanowire structure with noble metal gold particles at the tip. The diameter of the nanowire is 10~30nm, length 0.2~0.5um. The TEM photograph of the product is as imag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com