Polyesteramide and preparation method thereof

A technology of polyester amide and hexamethylene diamine, which is applied in the field of polymer material preparation, can solve the problems of high cost, less polyester amide, increased method complexity and the like, achieves low cost, improved solvent resistance and heat resistance, The effect of large application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

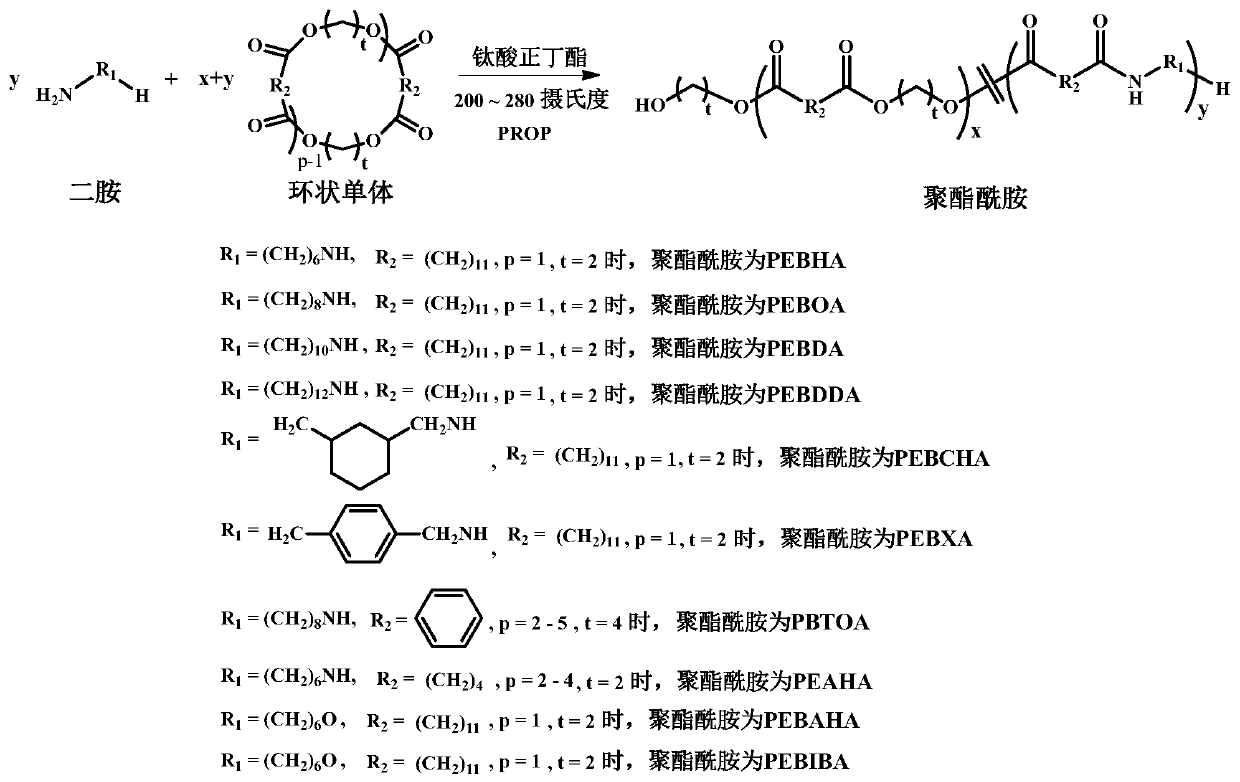

[0043] The preparation method of the above-mentioned polyester amide is as follows, using diamine or aminoalcohol as an initiator, using a macrocyclic lactone based on a diacid diol as a monomer, and preparing it by ring-opening-condensation cascade polymerization reaction in the presence of a catalyst Polyester amide with excellent mechanical properties, solvent resistance and thermal stability. The invention effectively solves the deficiencies in the prior art, such as low polyester glass transition temperature and crystallization temperature, poor heat resistance, low polyamide modulus, poor rigidity, and easy creep.

[0044] see figure 1 Shown is the preparation method of the polyester amide of the present invention, that is, a series of aliphatic polyester amide and semi-aromatic polyester amide are obtained through the ring-opening-condensation cascade polymerization method.

Embodiment 1

[0045] Example 1 Synthesis of aliphatic polyester amide poly(1,13-tridecanedioic acid ethylene glycol ester copolymerization by 1,6-hexamethylenediamine and musk T under nitrogen conditions for ring-opening-condensation cascade polymerization 1, 13-tridecane diamide (1,6-hexanediamine) (PEBHA)

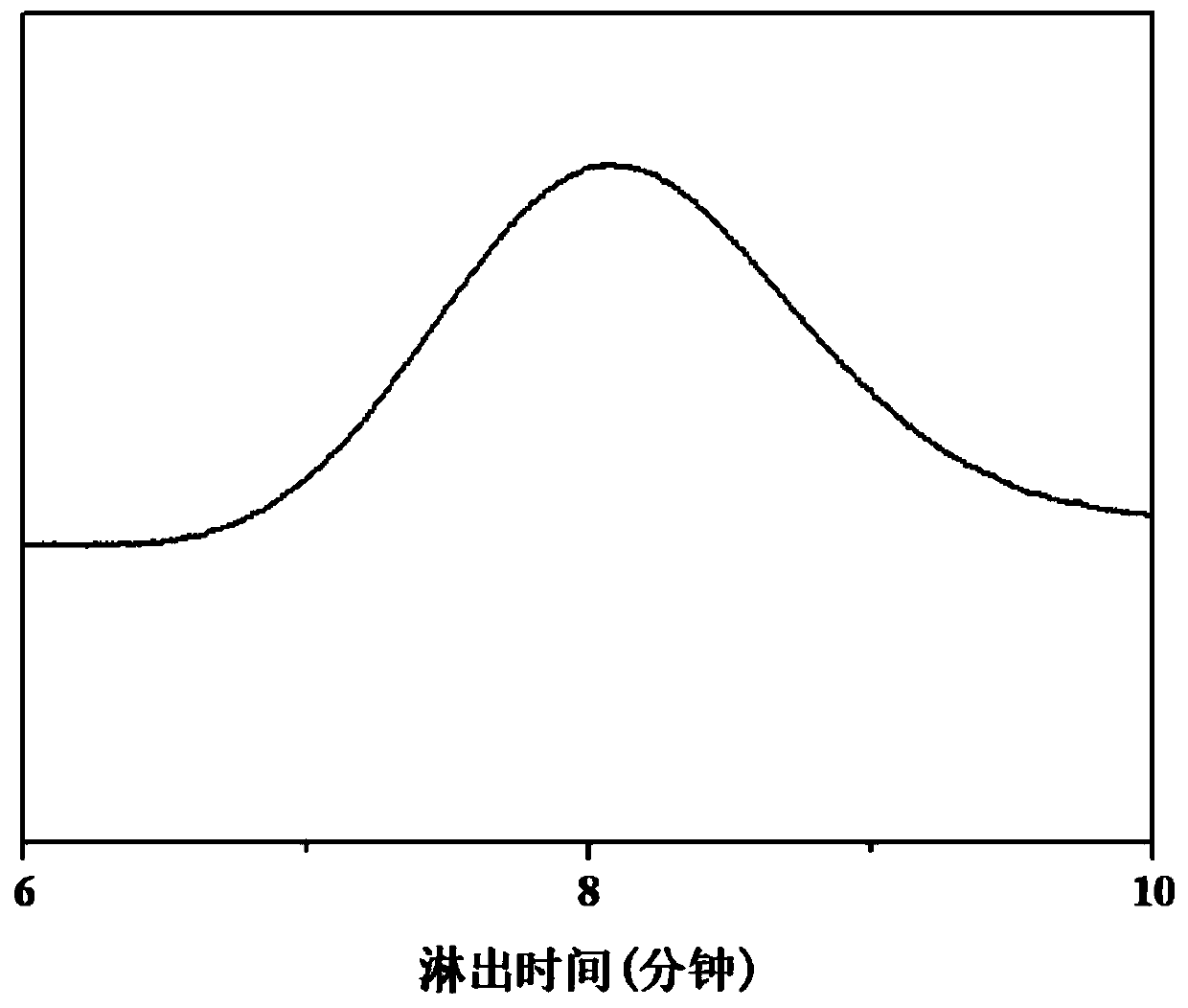

[0046] At room temperature, add 1,6-hexanediamine (1.00 g) and musk T (9.00 g) into a 250 ml single-necked flask, and slowly add 20.0 microliters of n-butyl titanate through a microsampler; then The one-necked flask was placed in a salt bath and heated to 240°C, with mechanical stirring, and vacuum polymerization for 60 minutes to finally generate the corresponding polymer PEBHA. For size exclusion chromatograms see figure 2 , and the measured molecular weight was 36.1 kg per mole, demonstrating the successful synthesis of the target product.

Embodiment 2

[0047] Example 2 Synthesis of aliphatic polyester amide poly(1,13-tridecanedioic acid ethylene glycol ester copolymerization 1, 13-Tridecanediyl 1,8-octanediamine) (PEBOA-1)

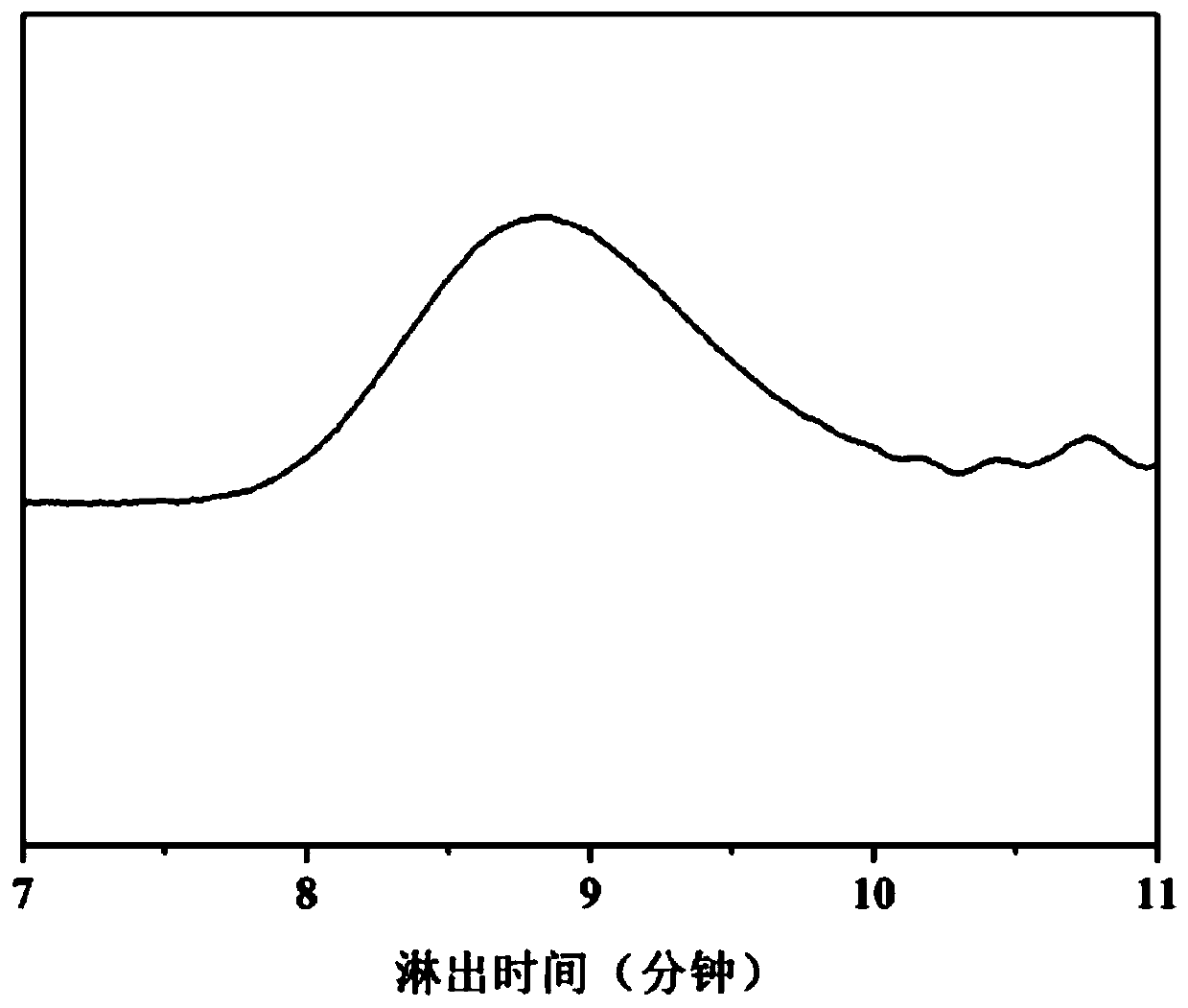

[0048] At room temperature, add 1,8-octanediamine (0.50 g) and musk T (9.50 g) into a 100 ml three-necked flask, and after blowing nitrogen to remove oxygen, place the three-necked flask in a salt bath and heat it to 220 °C, and After mechanical stirring, 20.0 microliters of n-butyl titanate was slowly added through a microsampler, and ring-opening-condensation cascade polymerization was carried out under nitrogen atmosphere for 60 minutes to generate the corresponding polymer PEBOA-1. For size exclusion chromatograms see image 3 , and the measured molecular weight was 8.30 kg per mole, demonstrating the successful synthesis of the target product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com