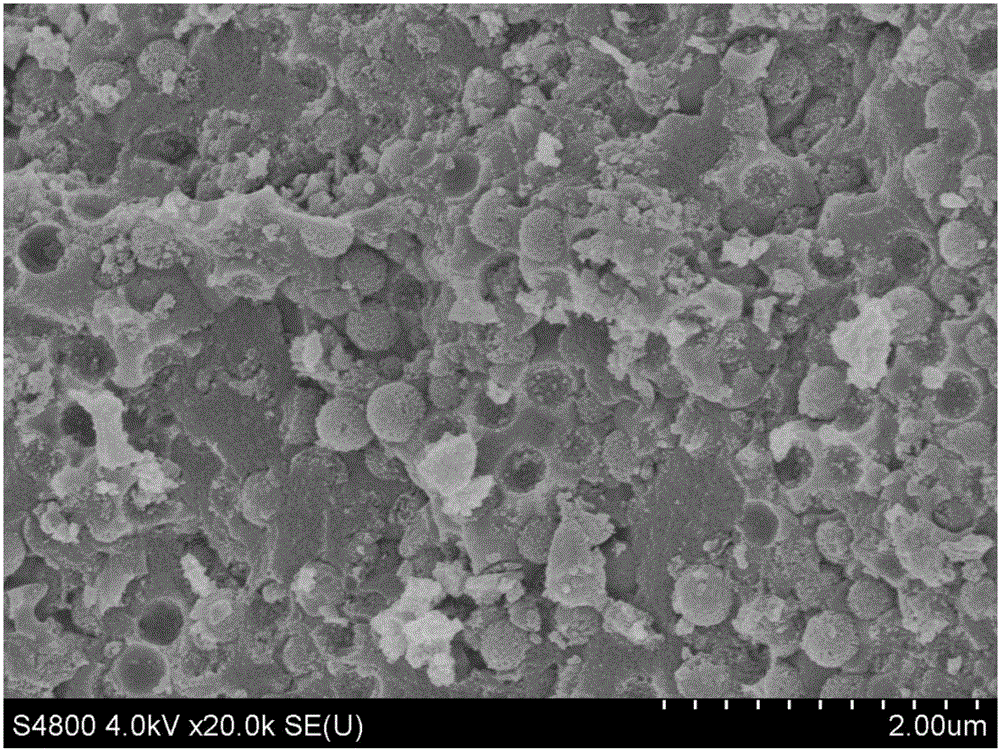

Honeycomb porous silicon/carbon composite material and preparation method thereof

A silicon-carbon composite material, carbon composite material technology, applied in nanotechnology for materials and surface science, electrical components, battery electrodes, etc., can solve problems such as poor conductivity, broken silicon particles, loss of electrical activity, etc. Simple, improve product purity, and avoid the effect of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]Step (1). Preparation of silica: use Stober method in alcohol phase medium, catalyze tetrabutyl orthosilicate (TEOS) with ammonia water, form monodisperse spherical silica particles through hydrolysis-condensation, and adjust the pH value Control the particle size at 400 nanometers;

[0048] Step (2). Manually mix the above 1g of silicon dioxide and 1g of magnesium powder at room temperature to obtain a mixture of 2g of silicon dioxide and magnesium;

[0049] Step (3). Package the above-mentioned mixture of silicon dioxide and magnesium in a crucible, place it in a tube furnace, control the heating rate to 4°C / min, heat to 700°C, and react at a constant temperature for 4 hours under an argon atmosphere, and then lower it to room temperature , to obtain the reduced crude product.

[0050] Step (4). The reduced crude product was placed in dilute hydrochloric acid with a concentration of 1 mol / L, stirred at room temperature for 4 hours, centrifuged to obtain a solid produc...

Embodiment 2

[0059] Step (1), preparation of silica: use Stober method in alcohol phase medium, catalyze tetrabutyl orthosilicate (TEOS) with ammonia water, form monodisperse spherical silica particles through hydrolysis-condensation, and adjust the pH value Control the particle size at 80 nanometers;

[0060] Step (2), at room temperature, mix the above-mentioned 1g of silicon dioxide with 0.5g of magnesium powder, and manually grind for 5 minutes in a mortar to obtain a mixture of silicon dioxide and magnesium;

[0061] Step (3), the above-mentioned mixture of silicon dioxide and magnesium is packaged in a crucible, placed in a tube furnace and heated to 650°C at a controlled heating rate of 4°C / min, reacted at a constant temperature for 24 hours under a nitrogen atmosphere, and then lowered to normal temperature, The reduced crude product was obtained.

[0062] Step (4), placing the reduced crude product in dilute hydrochloric acid with a concentration of 0.5 mol / L, stirring at room te...

Embodiment 3

[0070] Step (1). Preparation of silica: use Stober method in alcohol phase medium, catalyze tetrabutyl orthosilicate (TEOS) with ammonia water, form monodisperse spherical silica particles through hydrolysis-condensation, and adjust the pH value Control the particle size at 800 nanometers;

[0071] Step (2). Mix 10 g of the above-mentioned silicon dioxide with 15 g of magnesium powder at room temperature, and manually grind for 10 minutes in a mortar to obtain a mixture of silicon dioxide and magnesium;

[0072] Step (3). Package the above-mentioned mixture of silicon dioxide and magnesium in a crucible, place it in a tube furnace, control the heating rate to 1°C / min, heat to 1000°C, react at a constant temperature for 24 hours under an argon atmosphere, and then lower it to room temperature , to obtain the reduced crude product.

[0073] Step (4). The reduced crude product was placed in dilute hydrochloric acid with a concentration of 2 mol / L, stirred at room temperature for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com