Composite electrode material and preparation method and application thereof

A composite electrode and composite material technology, applied in electrode manufacturing, electrode rolling/calendering, negative electrode and other directions, can solve the problems of the discontinuous skeleton structure being difficult to stabilize, the improvement effect is not ideal, and the process operation is difficult, etc. The effect of reducing the uneven lithium deposition/dissolution area, good support, and good lithium affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

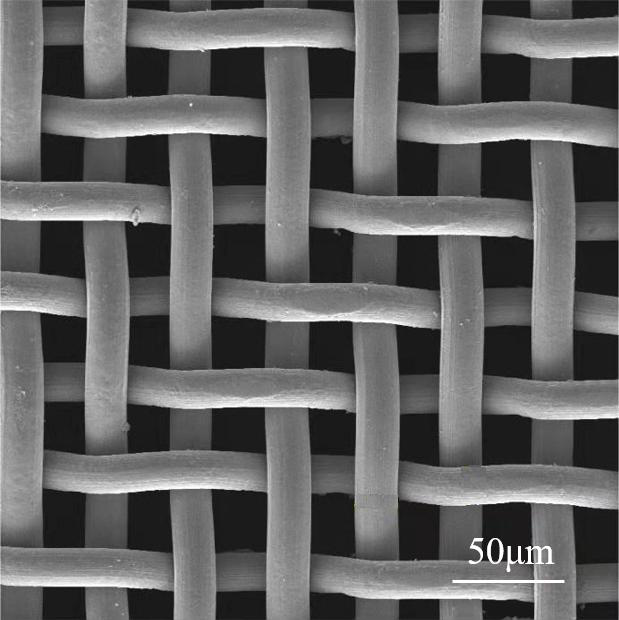

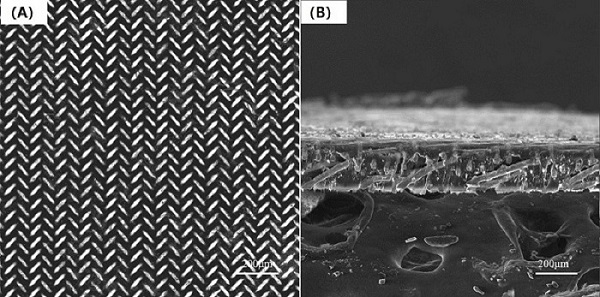

[0057] The grade is 316L, the thickness is 41 μ m, the stainless steel mesh of 635 mesh (such as figure 1 Shown) cut to a length of 50 cm and a width of 12 cm, soaked in industrial alcohol for 15 minutes, ultrasonically cleaned, taken out, and placed in a blast oven at 60°C for 12 hours to dry for later use. In an argon glove box with an oxygen content of image 3 shown.

Embodiment 2

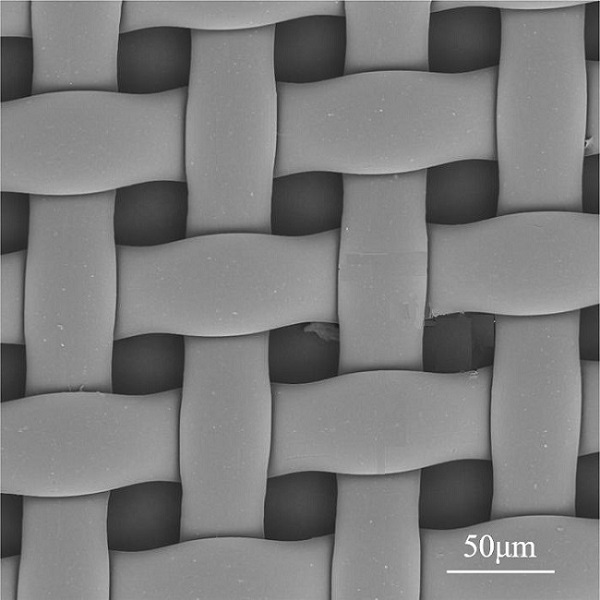

[0059] Thick 69μm, 425 mesh polyester mesh (PET, such as figure 2 As shown) cut to 50cm long and 12cm wide, soaked in denatured alcohol and ultrasonically cleaned for 15 minutes, then took out, and placed in a blast oven at 60°C for 12 hours to dry. In an argon glove box with an oxygen content of Figure 4 shown.

[0060] (1) Using Celgard 2400 as the diaphragm, 1mol lithium bis(trifluoromethylsulfonyl)immonium LiTFI / 1,2-dimethoxyethane DME+1,3-dioxolane (volume ratio 1 :1), electrolyte containing 2% Li2NO3 additive.

[0061] Assemble the CR2016 button battery with 84Li-B as the positive and negative electrodes to obtain the battery SymA;

[0062] Assemble the CR2016 button battery with 84Li-B@SSM as the positive and negative electrodes to obtain the battery SymB;

[0063] Assemble the CR2016 button battery with 84Li-B@PET as the positive and negative electrodes to obtain the battery SymC;

[0064] ① Put the three kinds of batteries at 1 mA / cm 2 Constant current charging...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com