Preparation method of hydrous salt-metal organic framework composite phase change material

A composite phase change material and metal-organic framework technology, applied in the field of composite materials and composite phase change materials, to achieve the effects of excellent heat transfer performance, avoiding phase change phase separation and supercooling, and improving heat storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

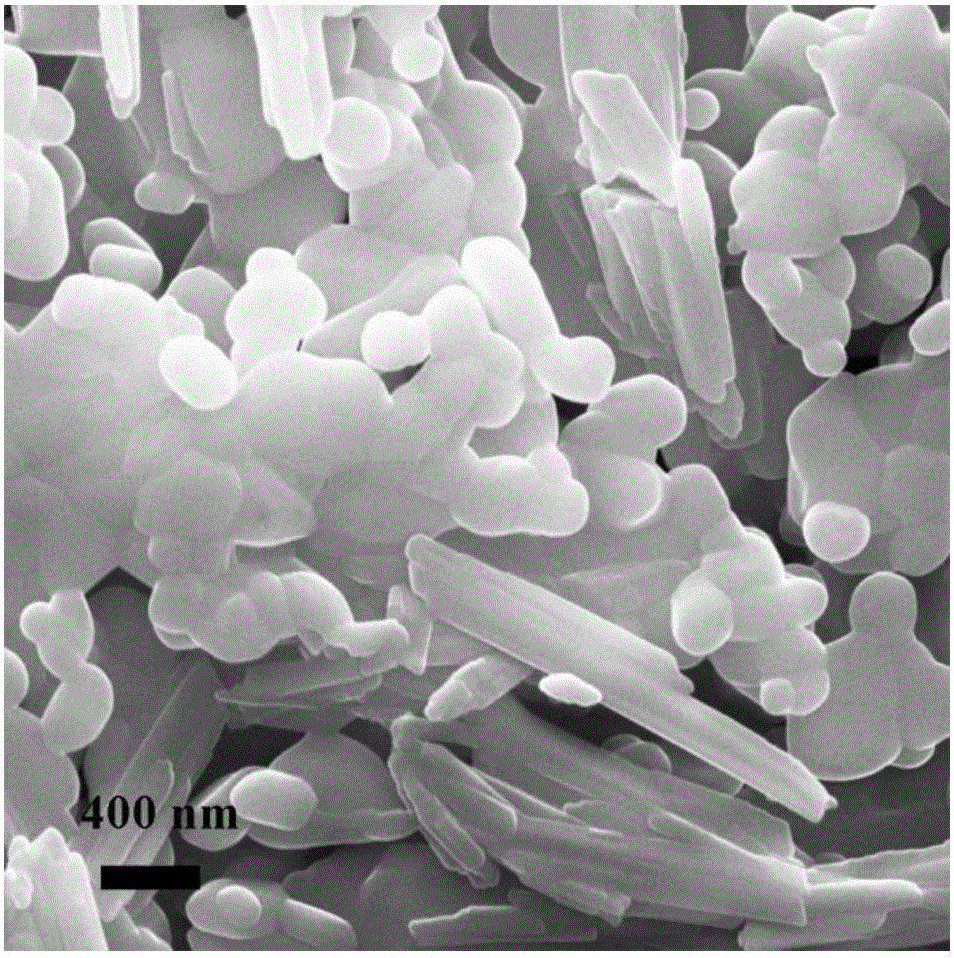

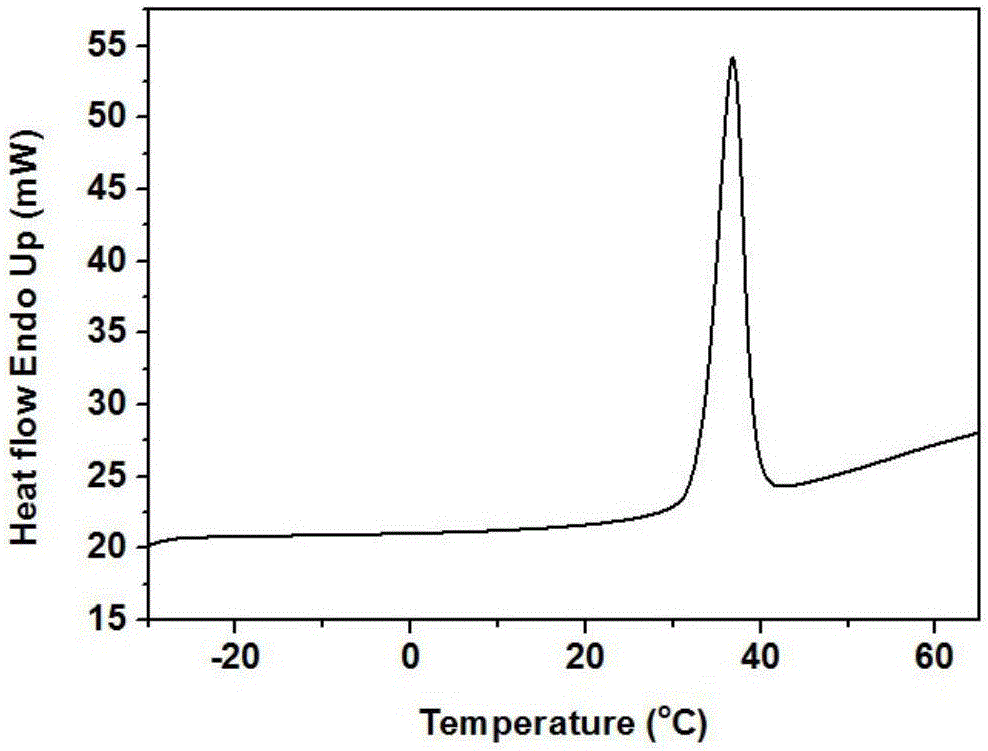

Image

Examples

Embodiment example 1

[0018] Blend 1.25g of copper sulfate pentahydrate, 0.7g of trimellitic acid, 2g of sodium sulfate decahydrate and 0.4g of strong sodium oxide, add 0.5g of water, mix well and seal it, put it in an oven, at 100°C Insulate for 4 hours, and after the reaction is completed, further mix evenly to obtain a sodium sulfate decahydrate-CuBTA composite phase change material.

Embodiment example 2

[0020] Blend 1.25g of copper sulfate pentahydrate, 0.7g of trimesic acid, 2.5g of sodium sulfate decahydrate and 0.4g of strong sodium oxide, add 1g of water, mix well and seal it, put it in an oven, at 100°C Keep it warm for 4 hours, and after the reaction is finished, mix it evenly to obtain a sodium sulfate decahydrate-CuBTC composite phase change material.

Embodiment example 3

[0022] Blend 1.96g of chromium sulfate hexahydrate, 0.64g of pyromellitic acid, 2.5g of sodium sulfate decahydrate and 0.4g of strong sodium oxide, add 1g of water, mix evenly, seal, put in an oven, and heat at 100°C Keep it warm for 4 hours, and after the reaction is finished, mix it evenly to obtain a sodium sulfate decahydrate-CrBTEC composite phase change material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com