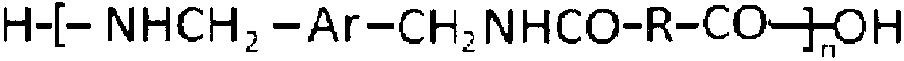

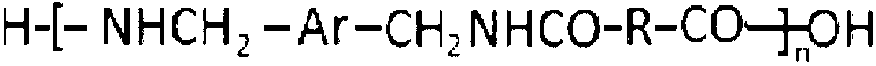

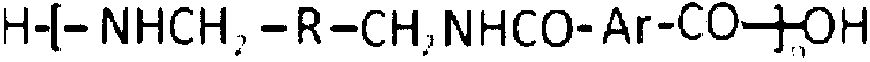

High modulus composition for emi shielding and molded articles thereof

A technology of electromagnetic shielding and composition, applied in the field of its molded products, can solve the problems of surface peeling, cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0125] The polyamide resins, metal fillers, and other additives listed in Table 1 were mixed in a typical mixer and extruded using a twin-screw extruder with L / D=35, φ=45mm to prepare pellet form Extrusion. The pellets were melted using a long shaft extruder. Then, the carbon fiber (B) was impregnated by a pultrusion method, followed by cutting into long pellets having a length of 12 mm. Test pieces for evaluation of applicability such as physical properties and EMI resistance at an injection temperature of 270° C. were prepared by injection molding to prepare long fibers. These test pieces were kept at 23° C. and 50% RH (relative humidity) for 48 hours, and then the physical properties were measured as follows. The results are shown in Table 1.

[0126] Evaluation of physical properties:

[0127] (1) Tensile strength: The tensile strength was evaluated at 5 mm / min according to ASTM D638. The unit of tensile strength is expressed in MPa.

[0128] (2) Flexural modulus: Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com