Smelting process for efficient and energy-saving secondary lead

A high-efficiency and energy-saving technology for secondary lead smelting, applied in the field of secondary lead smelting, can solve the problems of unsatisfactory treatment process for lead paste, difficulty in process stability control, and high process control requirements, and achieve low technical software and plant costs and low production costs. Low, good effect of sedimentation separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

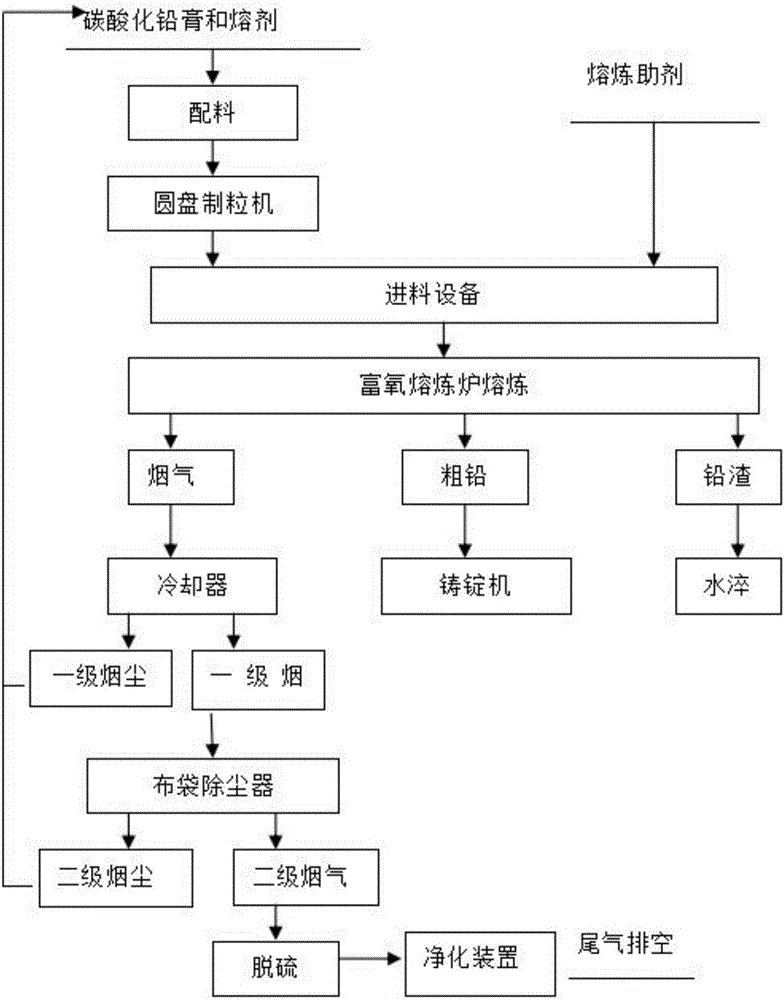

[0047] A high-efficiency energy-saving regeneration lead smelting process, comprising the following steps:

[0048] (1) After batching the carbonated lead paste mixture and flux according to the mass ratio of 5:1, it is granulated by a disc granulator to obtain lead paste granules. The humidity of the lead paste granules is 7 to 8%, and the particle size is 30 ~ 100mm, from the feeding port into the oxygen-enriched melting furnace for melting;

[0049] A smelting aid is added at the same time as feeding, wherein the amount of the smelting aid accounts for 1-2% of the weight of the lead paste pellets;

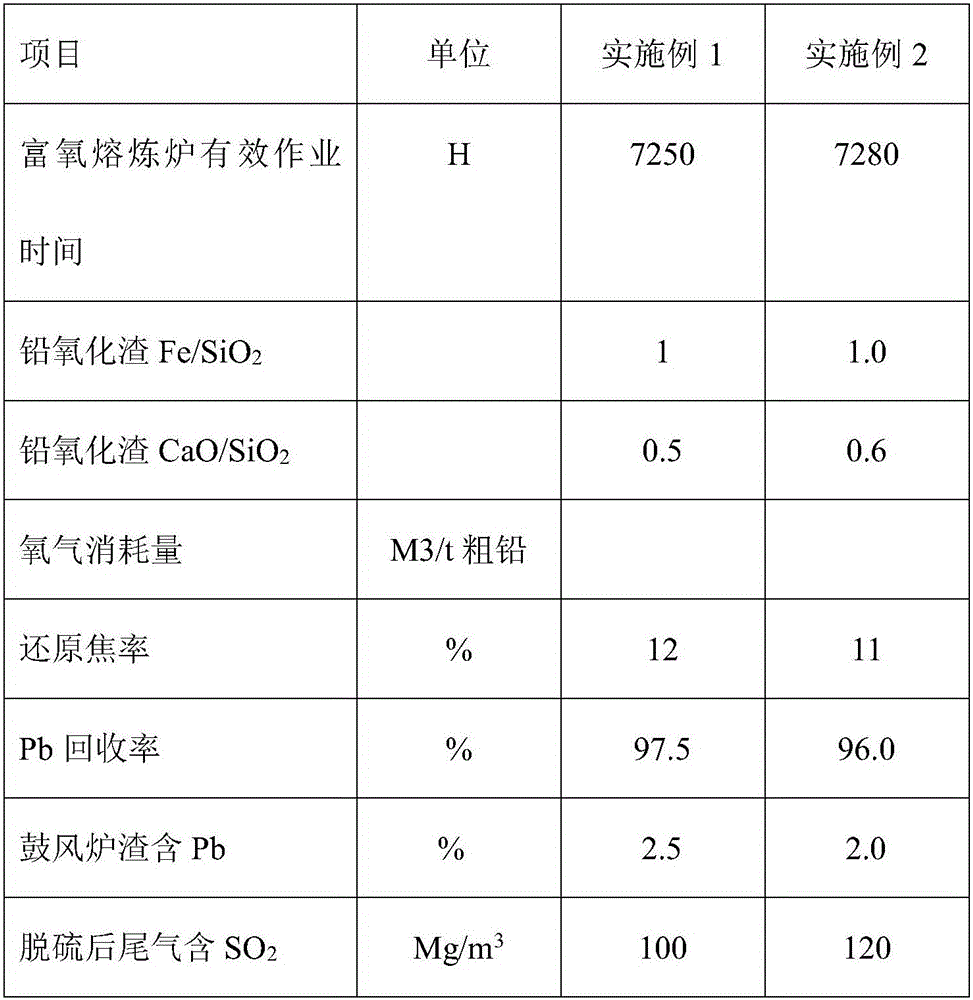

[0050] Among them, the selection of carbonated lead paste mixture should make the slag type of the produced high-temperature molten lead slag calculated by mass ratio: Pb≤2%, Fe / SiO 2 =1~1.4%, Ca0 / SiO 2 =0.4~0.8%;

[0051] (2) The oxygen-enriched gas required by the oxygen-enriched smelting furnace is sprayed into the oxygen-enriched smelting furnace through the oxygen-enrich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com