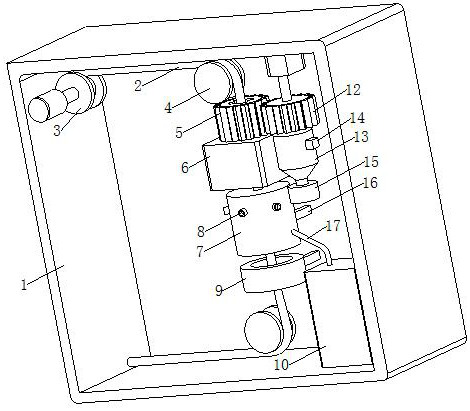

On-line detection system for film thickness on surface of enameled wire

A paint film thickness and detection system technology, which is applied in paint spraying booths, measuring devices, instruments, etc., can solve problems such as paint film breakage, affecting cable insulation performance, and different cable thicknesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

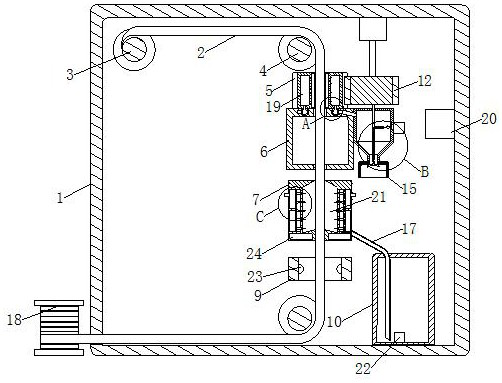

Method used

Image

Examples

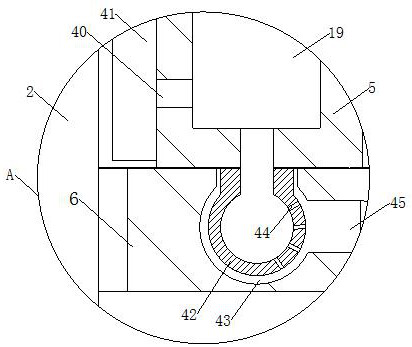

Embodiment approach

[0039]As an embodiment of the present invention, the paint repairing device includes a paint repair ring 7, a paint extraction pipe 17, an annular diffusion tank 21, an annular paint spray chamber 27, and a paint spray hole 28; the paint repair ring 7 is sleeved on the cable 2 Edge, and is positioned at the top of detection ring 9; Said annular diffusion groove 21 is positioned at the inner wall of paint repair ring 7, and the inside of paint repair ring 7 is positioned at the peripheral place of ring diffusion groove 21 and is provided with annular paint spray chamber 27, said ring paint spray chamber 27 and the annular dispersion tank 21 communicate with each other through the paint spray hole 28; the inside of the annular paint spray chamber 27 is provided with a flow control mechanism, and the bottom of the annular paint spray chamber 27 communicates with the top of the paint pipe 17, and the paint pipe The bottom of 17 stretches into the bottom of the paint box 10, the pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com