Titanium vacuum cup with high-airtightness vacuum thermal insulation cavity

A technology of vacuum heat insulation and high sealing, applied in the direction of drinking water vessels, etc., can solve the problems of reducing the internal vacuum degree, high vacuum degree requirements, loss of heat insulation function of cups, etc., to maintain vacuum degree, improve durability and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

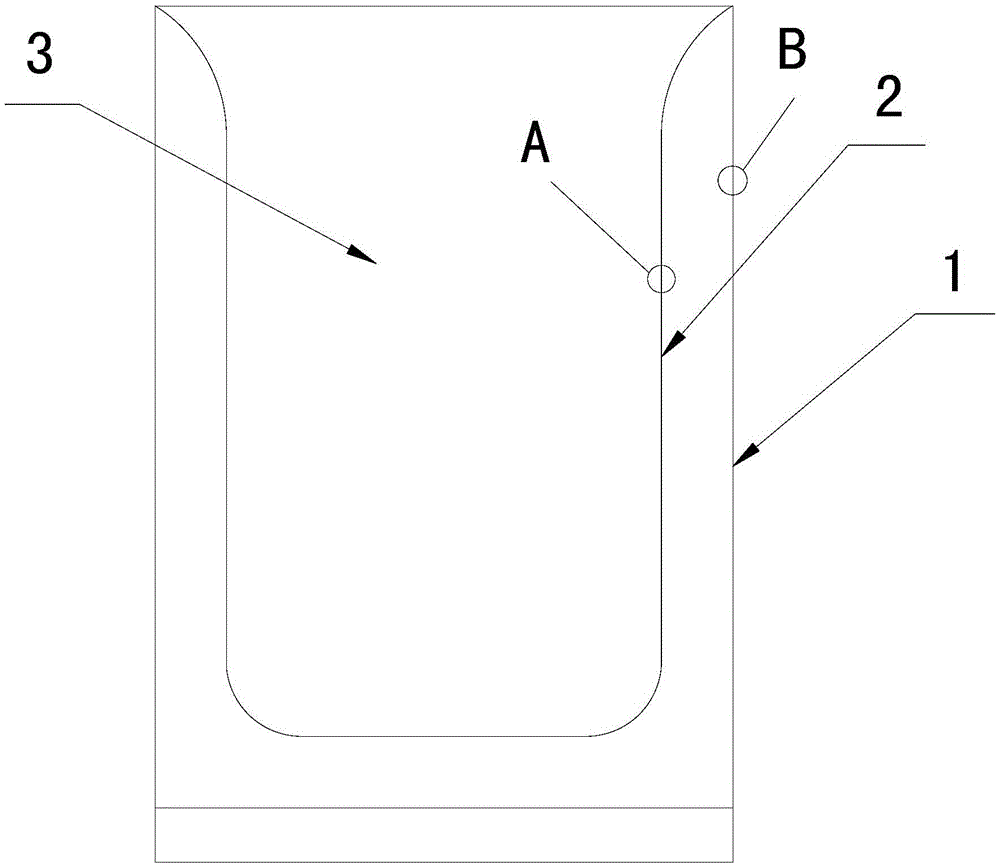

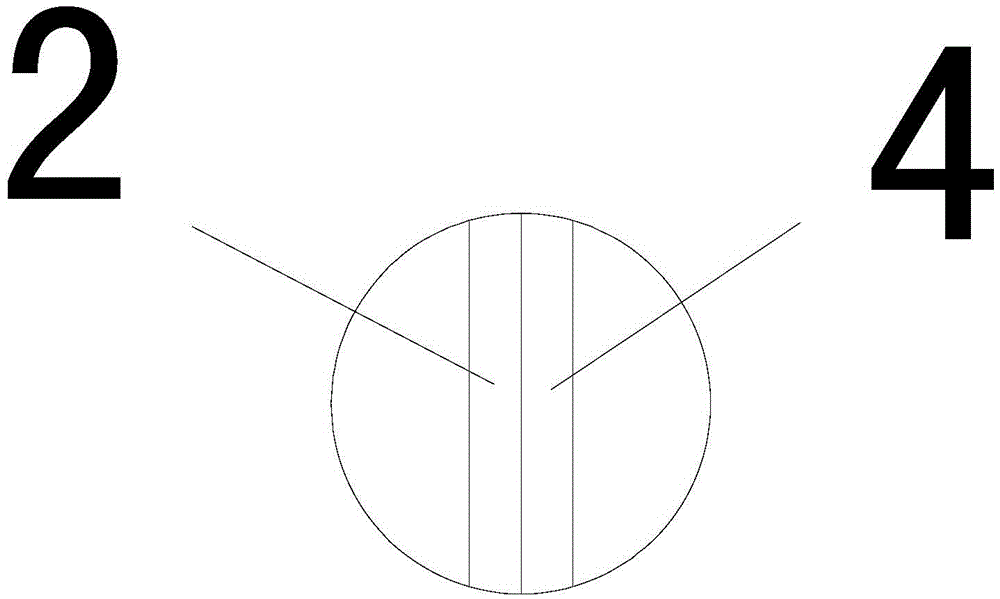

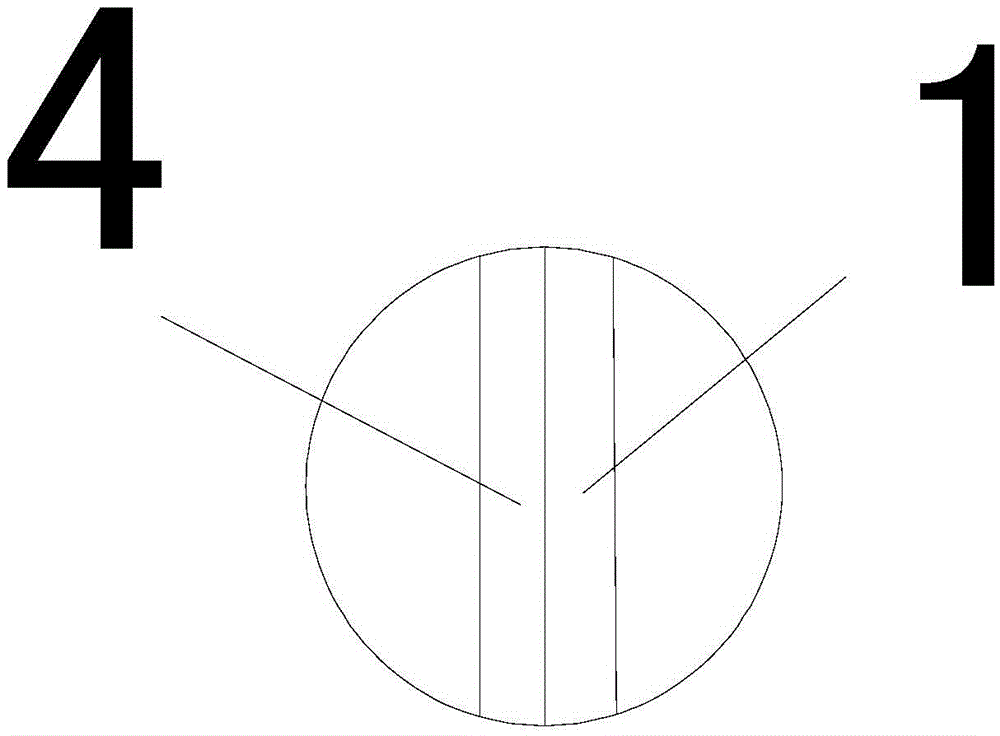

[0017] Example: Combined Figure 1~Figure 3 Shown is a specific embodiment of a titanium thermos cup with a high-tightness vacuum insulation chamber of the present invention, which has an outer shell 1, a cup liner 2 inside the shell 1, and a vacuum insulation between the shell 1 and the cup liner 2. In the thermal chamber 3 , a layer of nano-copper plating 4 is provided on the inner wall of the shell 1 and the outer wall of the cup liner 2 .

[0018] In this example, the shell 1 is U-shaped, and its upper part is fixed or integrally connected with the top peripheral edge of the cup liner 2 . As an example, the thickness of the nano-copper coating used in this case is 4 μm.

[0019] The nano-copper coating in this example is made with a particle size of 10~30nm (average particle size 20nm) and a specific surface area of 10~35m 2 / g copper plating solution made of nano-copper powder. Of course, the specific principle and method of electroplating can be referred t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com