Continuous lead smelting clean production process

A technology for cleaner production and production process, applied in the direction of improving process efficiency, can solve the problems of high implementation cost, reduce production links, environmental pollution, etc., and achieve the improvement of operating environment, reduction of production equipment and production links, and saving engineering investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

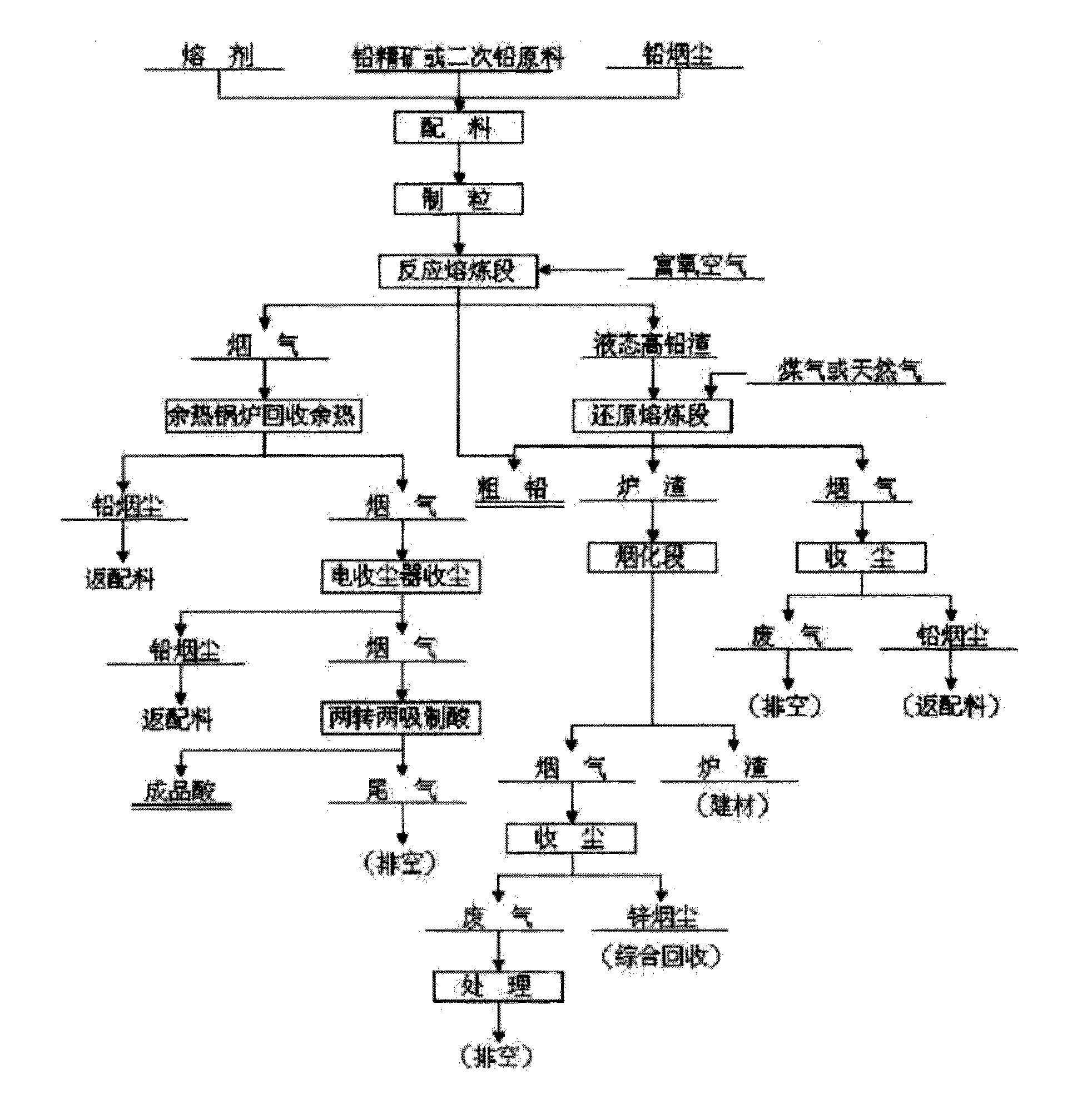

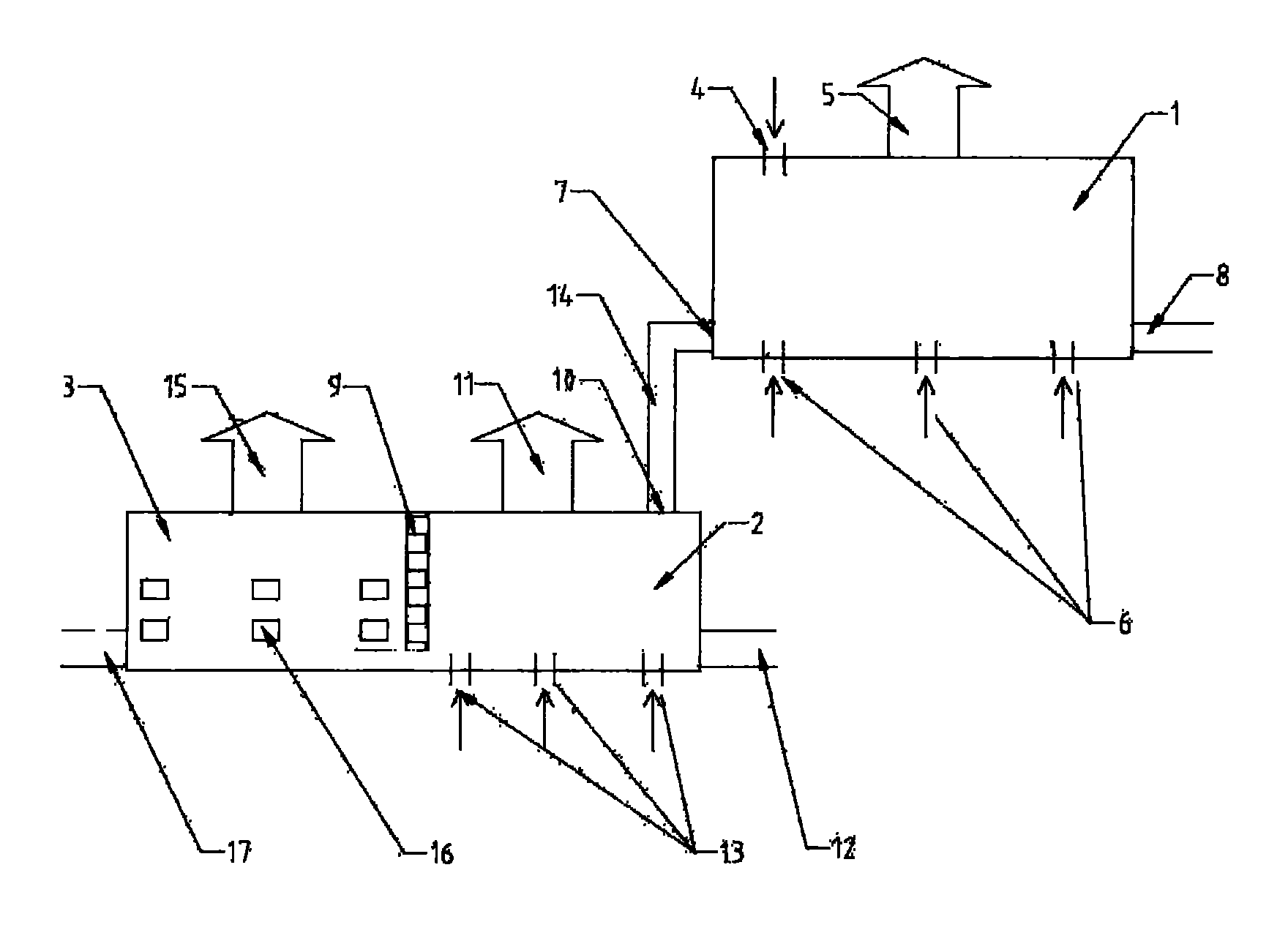

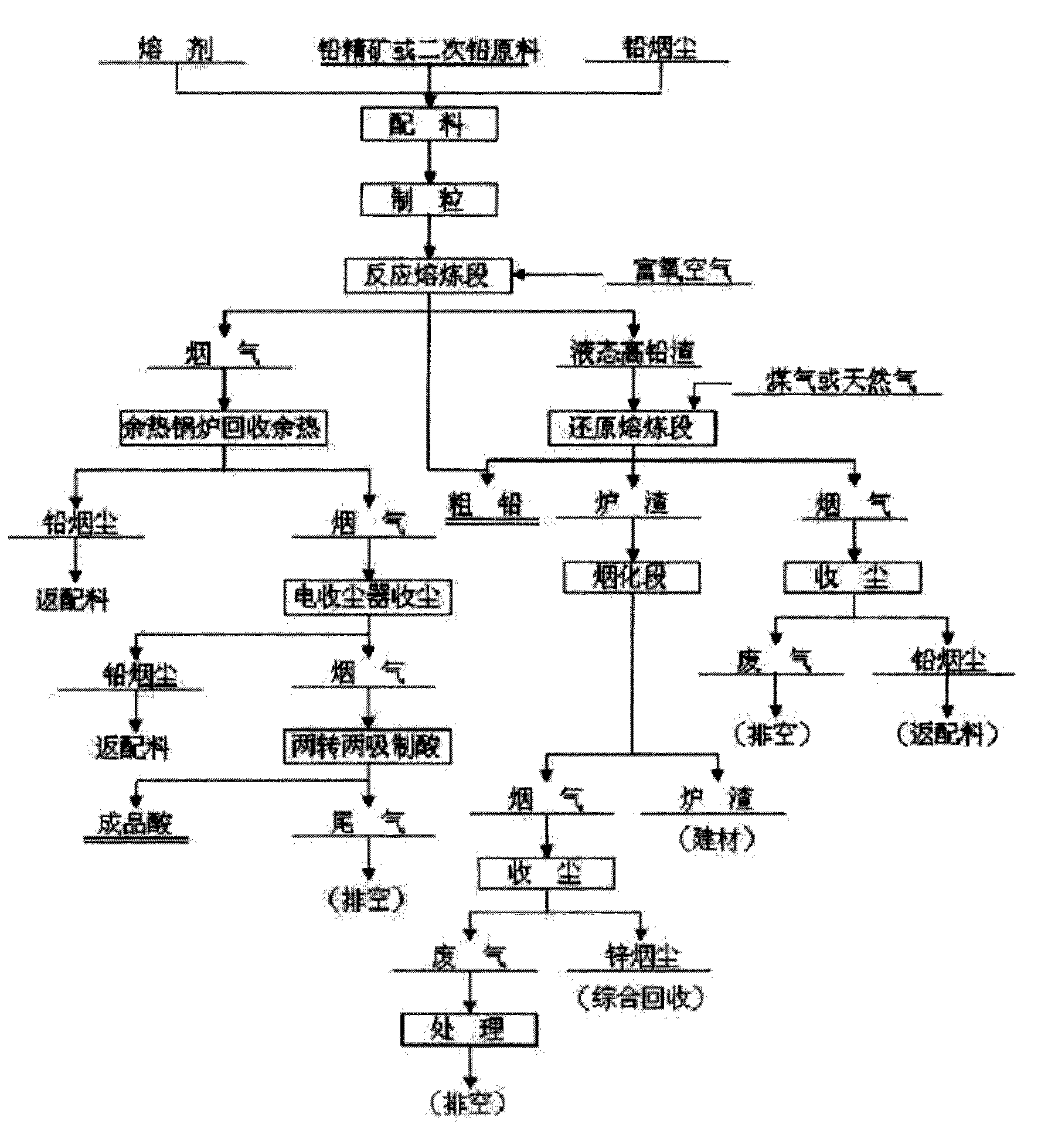

[0024] refer to figure 1 with figure 2 As shown, a continuous lead smelting clean production process, its specific production process steps: after batching lead concentrate or secondary lead raw materials and flux into charge, it is sent to the reaction smelting section from the feeding port 4 of the smelting equipment for smelting, from the oxygen Injection port 6 continuously injects oxygen-enriched gas into the molten pool of the smelting equipment; controls the melting temperature of the molten pool to be 1000-1200°C; 2 flue gas; containing high concentration of SO 2 The flue gas from the waste heat boiler and the electric precipitator collects the lead fume and sends it to the sulfuric acid system for acid production, and the acid production tail gas is emptied; the lead fume of the electric precipitator returns to the batching; the high-lead slag melt from the reaction smelting section The slag outlet 7 directly enters the reduction smelting section 2 through the chut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com