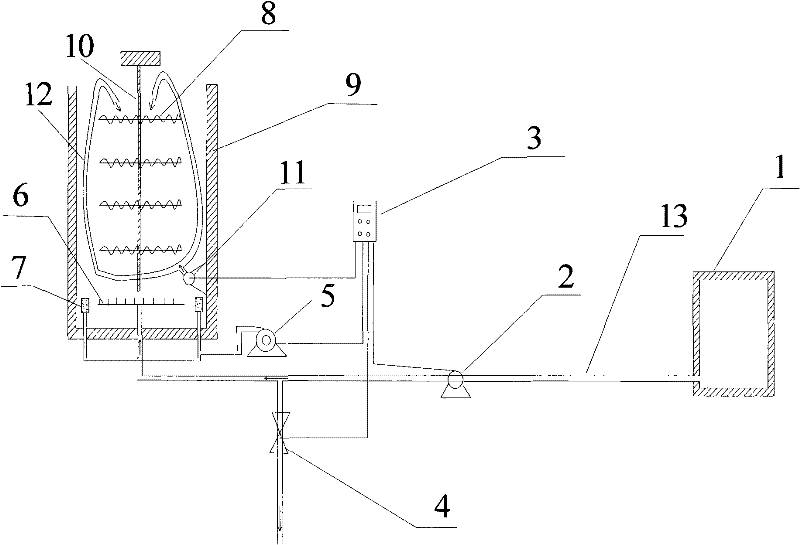

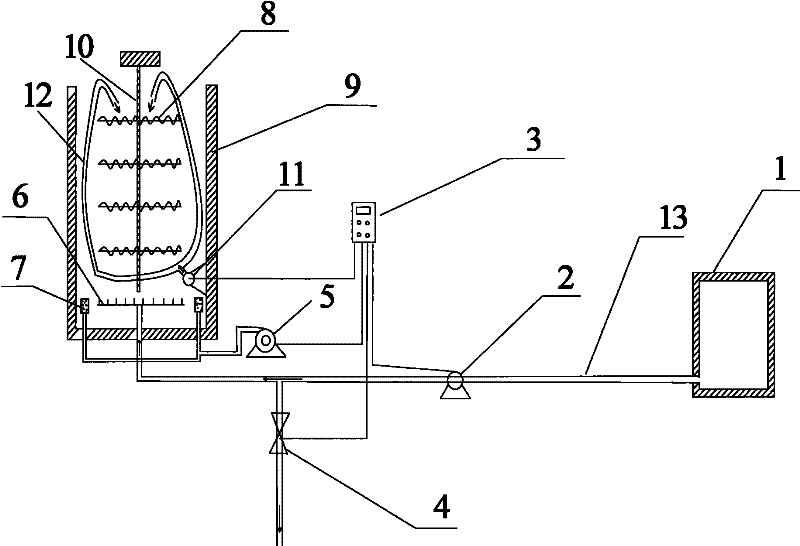

Internal recycle sequencing batch type biomembrane wastewater treatment device

A sewage treatment device and sequencing batch biofilm technology, which is applied to the field of internal cycle sequencing batch biofilm sewage treatment devices, can solve the problems of large shear force of the bottom biofilm, influence on the growth of biofilm, complicated process flow, etc. The precipitation water quality is good, the ability to resist external environmental changes is strong, and the treatment effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The volume of the internal circulation sequence batch type biofilm sewage treatment reactor is 10L, and fiber filler is added inside. After the film formation is successfully started, water will start to enter. Influent water quality: COD Cr 90~110mg / L, NH 4 + -N 1~2mg / L, NO 3 - -N 10~20mg / L, pH 7~7.2. The operating conditions adopted are: instantaneous water intake, anoxic stirring reaction for 3-4 hours, aerobic aeration reaction for 1-2 hours, anoxic stirring reaction for 1-2 hours, precipitation for 1 hour, and instantaneous drainage. Treatment effect: COD cr The removal rate is 90%, the removal rate of ammonia nitrogen is 100%, and the removal rate of nitrate nitrogen is 99%. The effluent water quality meets the first-class discharge standard of urban sewage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com