Method for sealing gas drainage boreholes at specified positions

A technology for gas drainage and drainage pipes, which is applied in the direction of sealing/packing, drill pipes, drilling pipes, etc. It can solve the problem of jamming at the deformation of the baffle plate or veil, failure to feed the gas drainage pipe, and poor sealing effect To solve problems such as good or bad, to achieve the effect of prolonging the effective extraction period, convenient operation, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

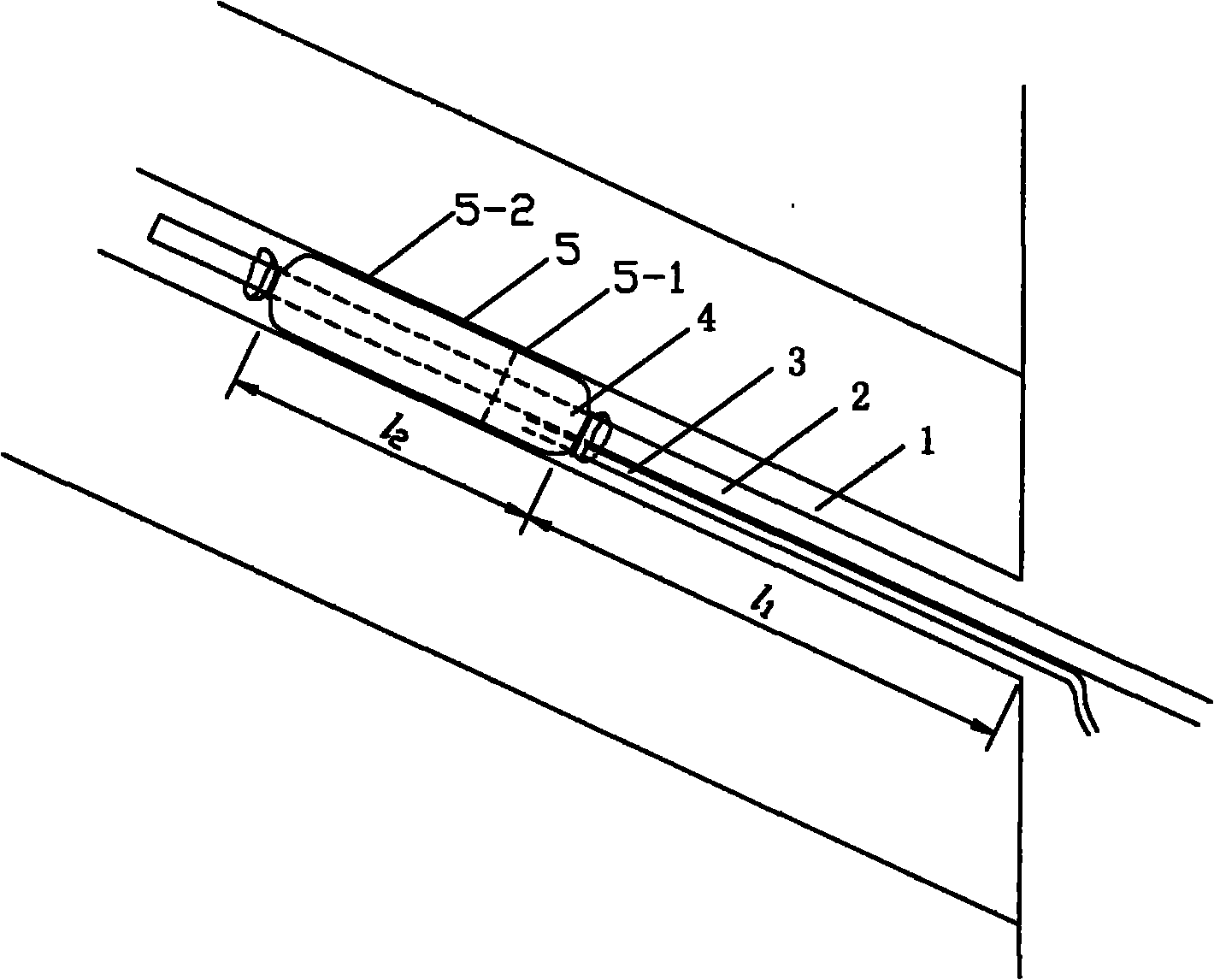

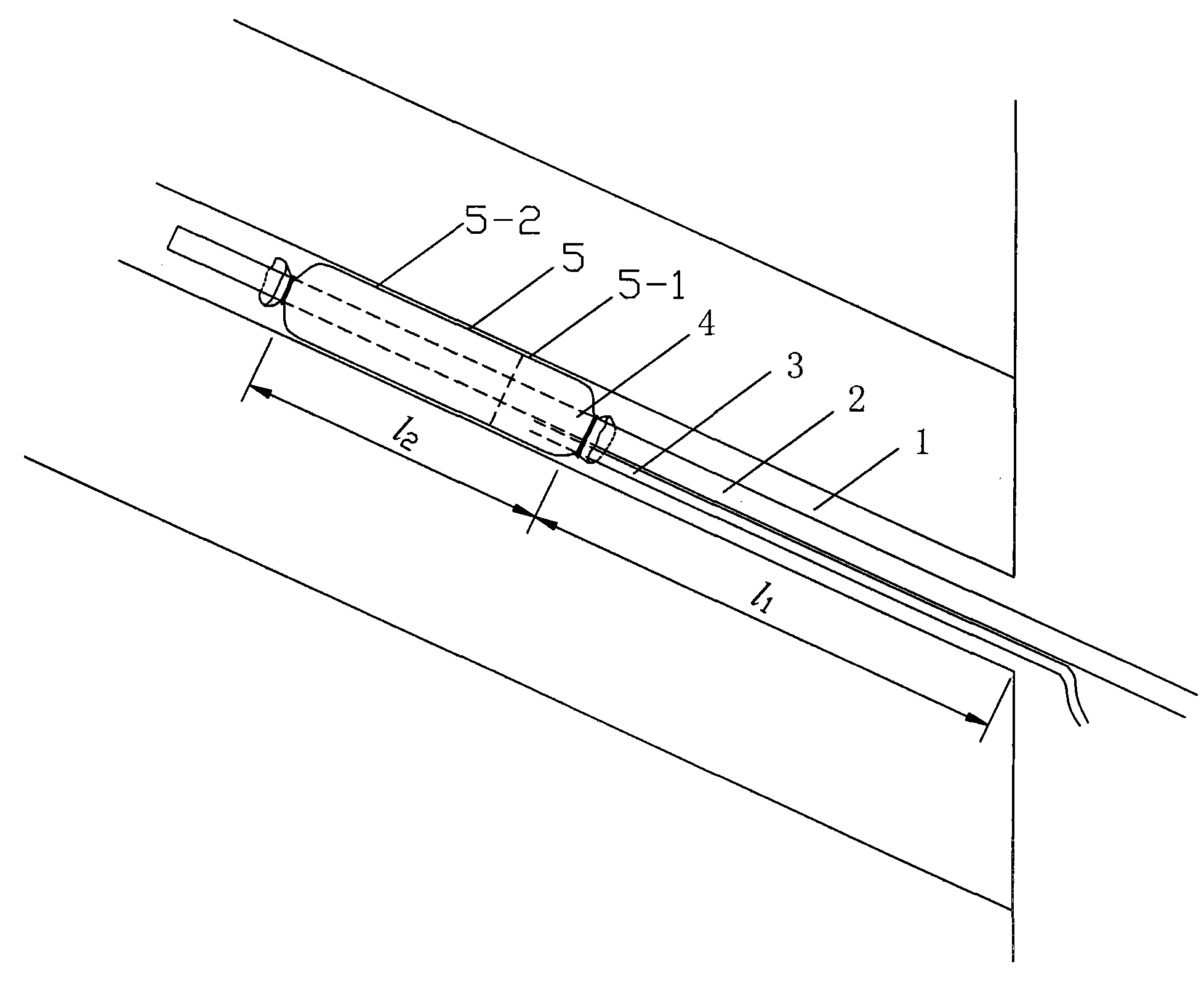

[0019] Embodiment one, figure 1 As shown, the method of sealing the ascending hole: the front part of the gas extraction pipe 2 to be inserted into the gas extraction hole 1 is covered with a cotton cuff section 5-2 and an antistatic tarpaulin cuff section 5-1. The total length l 2 The diameter of the flexible cuff 5 is larger than that of the gas drainage borehole 1, so that the sealing filling material 4 can contact the wall of the gas drainage borehole 1 after expanding. Cotton cuff section 5-2 faces inward, antistatic tarpaulin cuff section 5-1 faces outward, and the pore size of cotton cuff section 5-2 is 0.3-2 mm, allowing the liquid sealing filling material 4 to be placed on the cotton cloth A small amount of infiltration can be carried out when it flows upwards, which is beneficial to combine with the drainage hole wall; the length of the antistatic tarpaulin cuff section 5-1 is 0.3-1m to ensure that the slurry does not leak out. Insert the grouting tube 3 into the f...

Embodiment 2

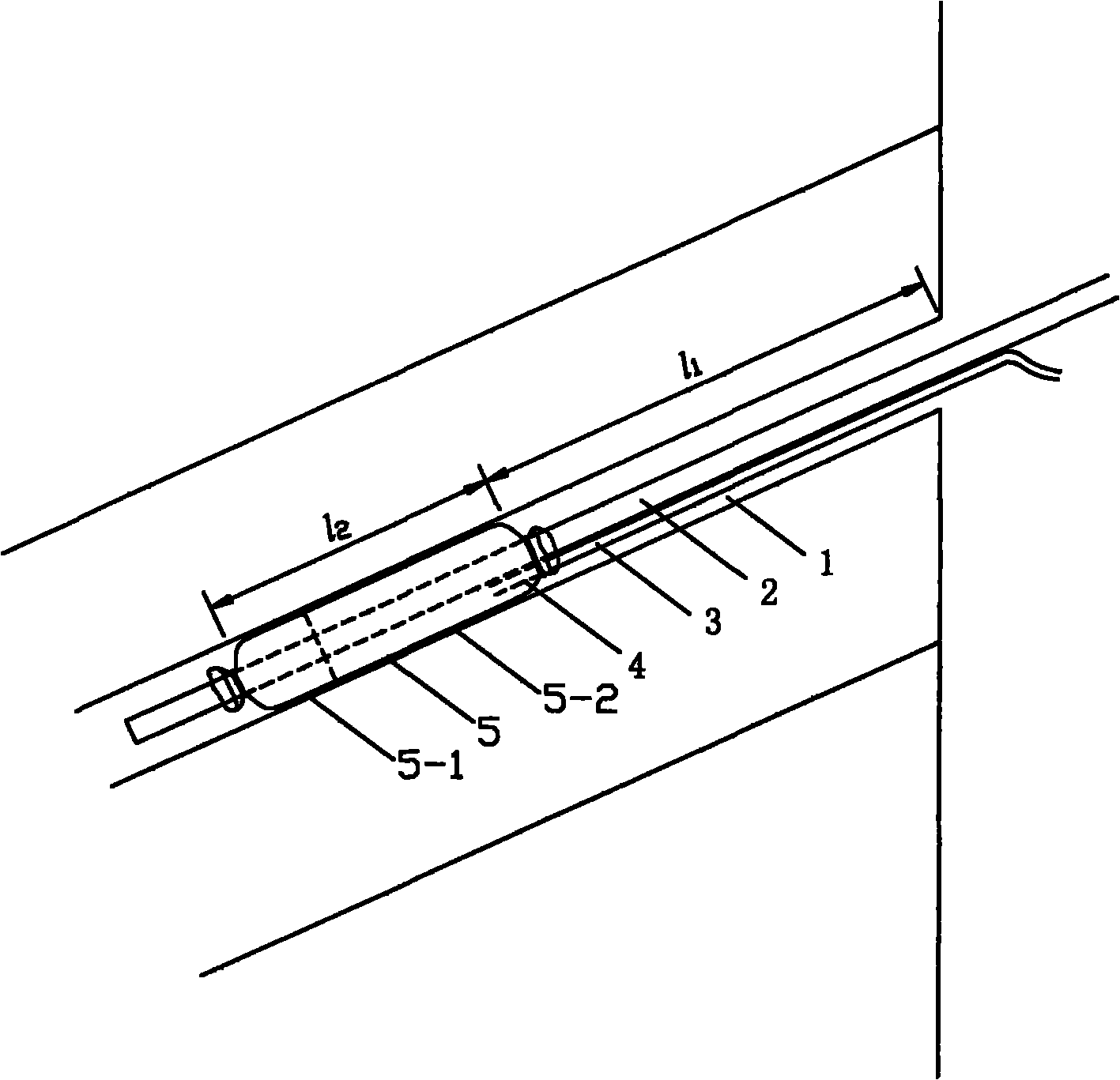

[0020] Embodiment two, figure 2 As shown, the method of sealing the down hole: since the angle direction of the sealing hole is downward, which is opposite to the angle direction of the upward sealing hole, the cotton cuff section 5-2 and the antistatic tarpaulin are set on the front part of the extraction pipe 2. The total length l of cuff segment 5-1 2 The flexible cuff 5 of 2~4m is also opposite, promptly the cotton cuff section 5-2 outwards, the waterproof cloth cuff section 5-1 section of antistatic is inward, and other is all identical with embodiment one, identical part is omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com