Telescopic type pulling hole packer

A telescopic, hole-sealing technology, which is used in gas discharge, safety devices, mining equipment, etc., can solve the problems of high drilling quality requirements, poor sealing effect, and low sealing quality in the sealing section. Shorten working time, reduce maintenance effort and cost, and make the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

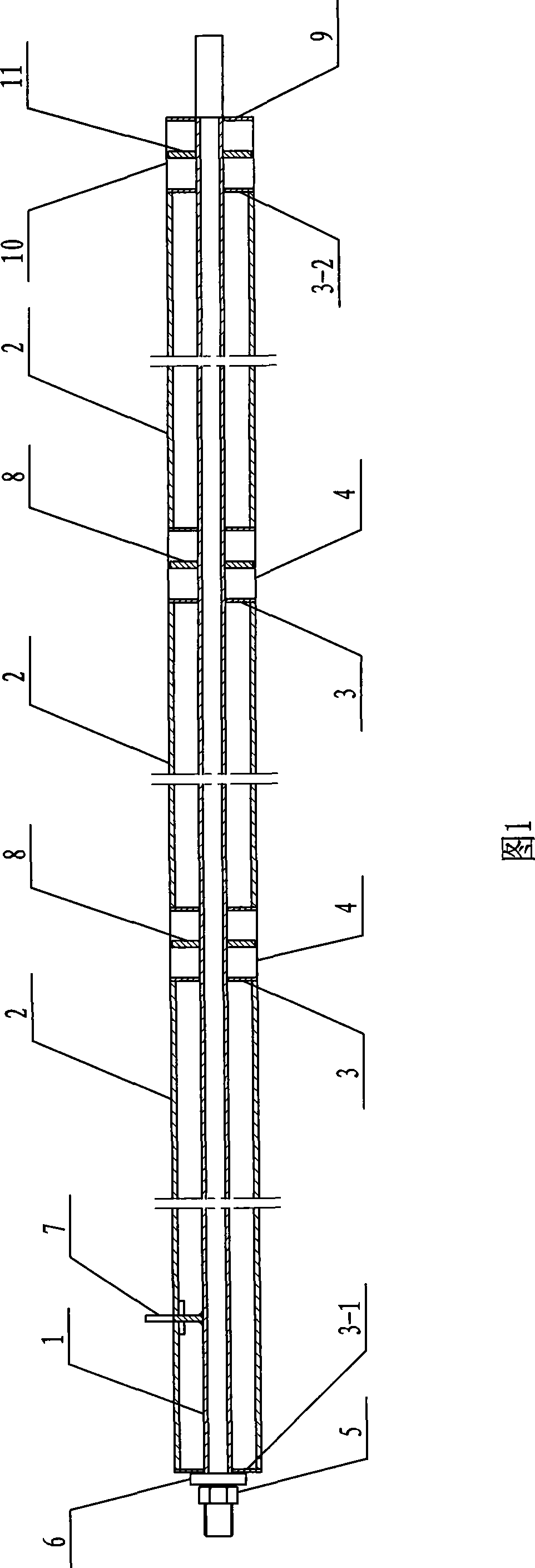

[0011] As shown in Figure 1, the telescopic extraction and sealing device of the present invention comprises an extraction tube 1, and a coaxial sealing tube 2 is set on the outside of the extraction tube 1, and the extraction tube 1 and the sealing tube 2 are without seam steel pipe, the drainage pipe 1 is longer than the sealing pipe 2, there are three sealing pipes 2, the two ends of the sealing pipe 2 are provided with blocking plates 3, and the blocking plates 3 of adjacent sealing pipes 2 are provided with the same The cylindrical airbag 4 of the shaft, the blocking plate 3 is bonded to the airbag 4, and the coaxial flat pad 8 is installed on the discharge pipe 1 inside the airbag 4, and the discharge pipe 1 penetrates the blocking plate 3 and the airbag 4 and rotates with them Connected, the air bag 4, the flat pad 8 are consistent with the outer diameter of the sealing tube 2. The outside of the blocking plate 3-1 at the rear end of the sealing pipe 2 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com