Gas-liquid proportioning mixed foam maker of compressed gas foam fire-fighting system

A compressed gas and foam fire extinguishing technology, applied in fire rescue and other directions, can solve the problems of low foaming ratio, large fire scale, low utilization rate of water and foam liquid, etc. long time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

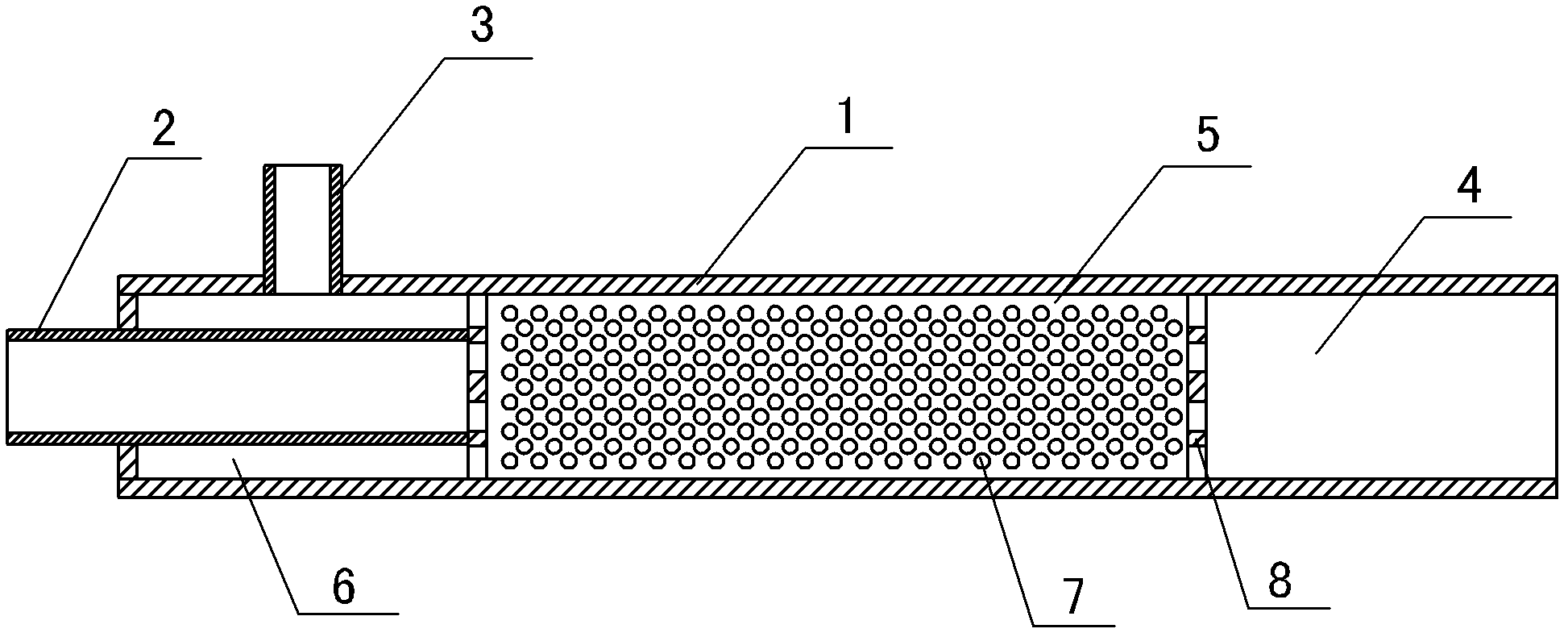

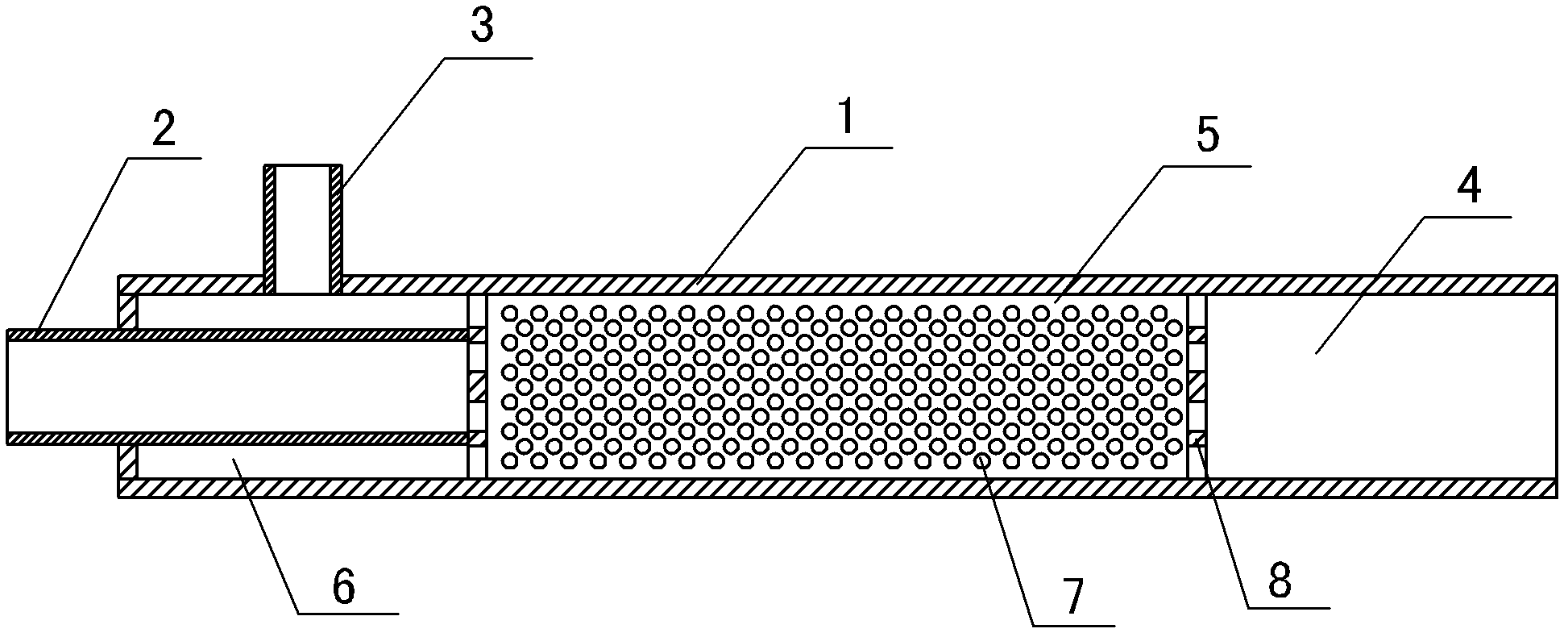

[0012] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0013] Such as figure 1 As shown, one end of the housing 1 is connected with a foam liquid inlet pipe 2 and a compressed gas inlet pipe 3, and the other end is an output chamber 4, and the mixing and foaming chamber 5 occupies the inner middle of the housing 1, and the input of the mixing and foaming chamber 5 The end is connected with the foam liquid inlet pipe 2 and the air chamber 6, wherein the air chamber 6 is the space surrounded by the inner wall of the shell 1, the outer wall of the foam liquid inlet pipe 2 and the mixing and foaming chamber 5, and the air chamber 6 is connected with the compressed gas inlet pipe 3 Communication, the output end of the mixing and foaming chamber 5 communicates with the output chamber 4, the mixing and foaming chamber 5 is filled with refined ceramic balls 7, and the two ends of the mixing and foaming chamber 5 are stainle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com