Flat steel bifurcated pipe and manufacturing method thereof

A manufacturing method and technology of steel bifurcated pipes, applied to pipes, branch pipelines, pipes/pipe joints/pipe fittings, etc., can solve the problems that cannot consider the requirements of self-flowing drainage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

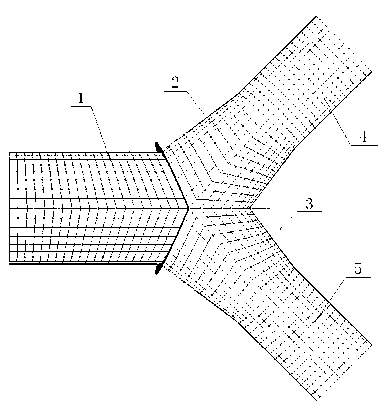

[0053] The flat-bottomed steel branch pipe of the present invention comprises a main pipe 1, a left support cone 2 whose one end communicates with an end of the main pipe 1, a right support cone 3 whose one end communicates with an end of the main pipe 1, a side of the left support cone 2 and a right branch One side of the cone 3 is attached and fixed by welding; the other end of the left cone 2 and the other end of the right cone 3 are respectively connected with a left branch pipe 4 and a right branch pipe 5, and the main pipe 1, the left cone 2, and the right cone 3 The bottoms of the left branch pipe 4 and the right branch pipe 5 are all located at the same elevation.

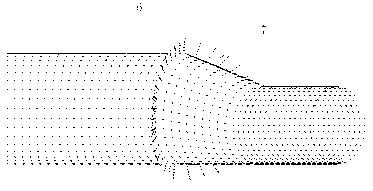

[0054] Among them, a waist beam 6 is provided along the outer wall of the main pipe 1 at the connection between the left support cone 2 and the right support cone 3 and the main pipe 1; a U-shaped frame 7 is provided circumferentially at the welding and fixing place between the left support cone 2 and the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com