Foam detecting method of washing machine

A detection method and washing machine technology, applied in the control device of washing machine, other washing machines, washing devices, etc., can solve the problems of increased after-sales service factors, reduced product reliability, fire occurrence, etc., to eliminate after-sales service factors and avoid disadvantages. Affect, increase the effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

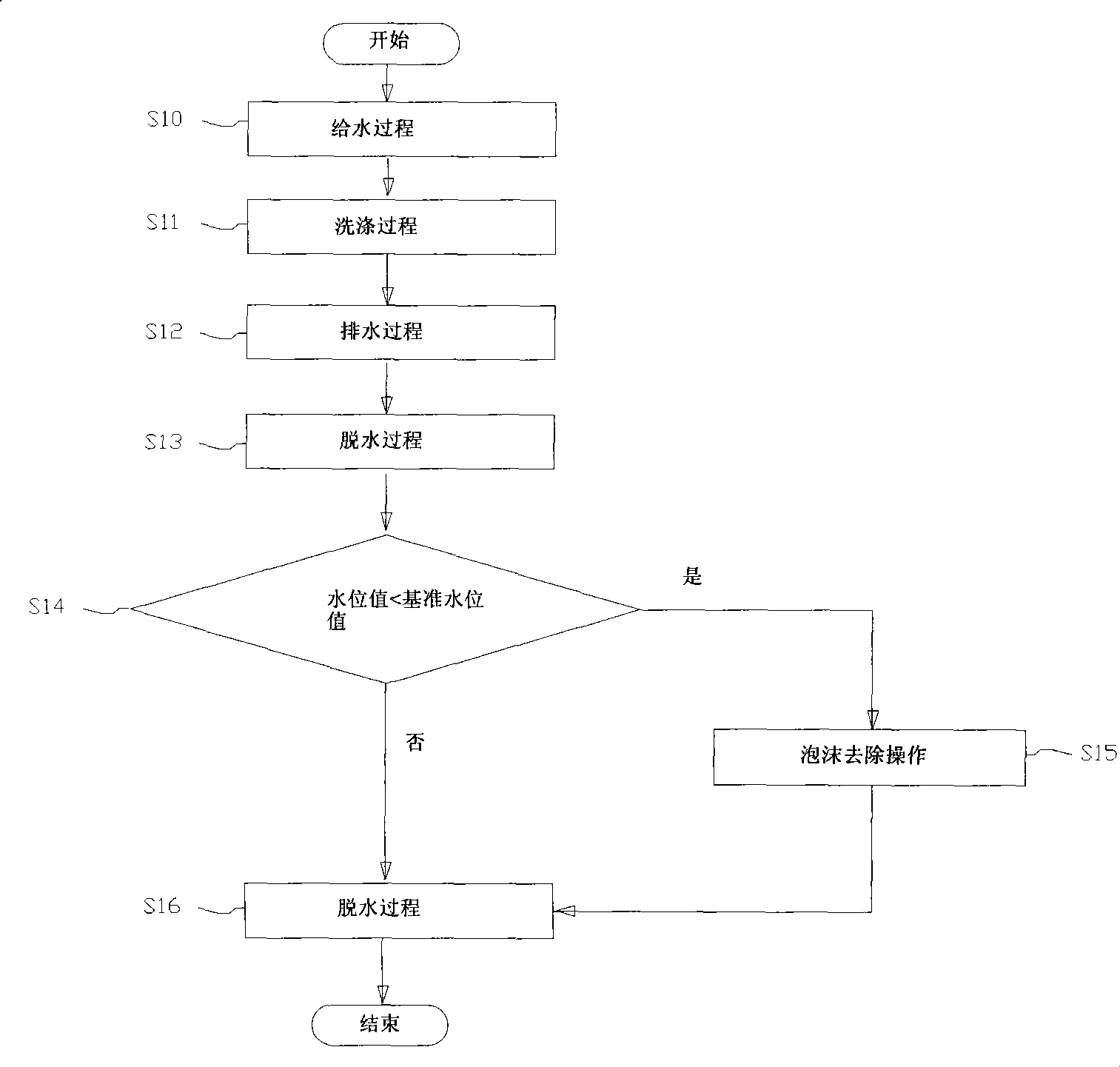

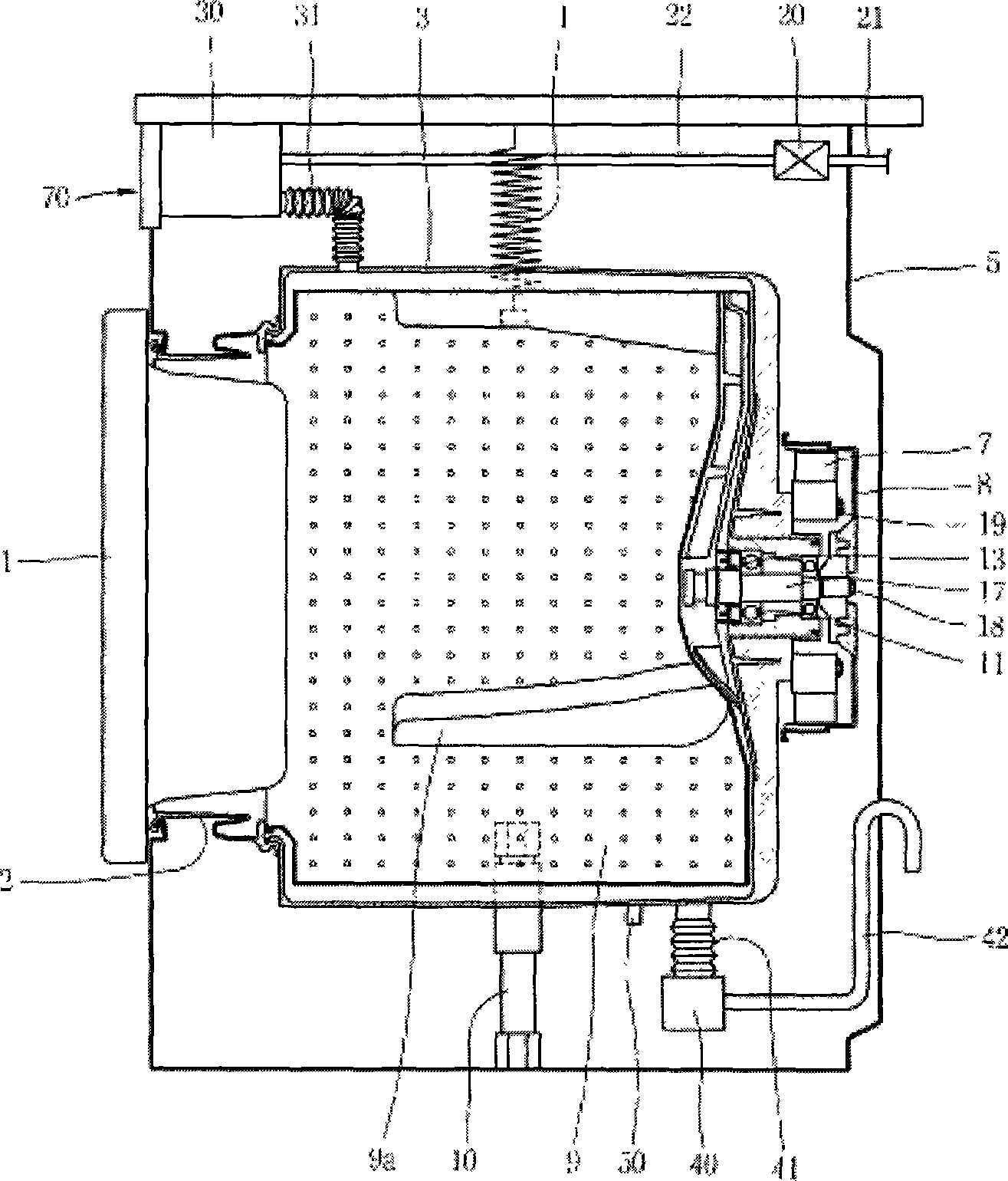

[0024] Next, a method for detecting foam in a washing machine in an embodiment of the present invention will be described in detail. image 3 is a schematic diagram of a washing machine implementing the foam detection method in an embodiment of the present invention; Figure 4 is included image 3 Flowchart of the washing stroke of the suds detection method.

[0025] refer to image 3 , the washing machine that implements the foam detection method in an embodiment of the present invention includes: a housing 5 forming an appearance; a washing tub 3 installed inside the housing 5 and used to store washing water; rotatably installed in In the above-mentioned washing drum 3, and for putting in the drum 9 of washing; for rotating the washing motors 7, 8 of the above-mentioned drums 9; for transferring the rotational force of the washing motors 7, 8 to the rotating shaft 17 of the above-mentioned drums 9; The bearing 11 for supporting the above-mentioned rotating shaft 17; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com