Method for reinforcing outburst-prone coal seam cross-cut coal uncovering

A technology for coal excavation and coal seam in Shimen, which is applied in the field of rapid coal excavation in Shimen, can solve the problems of reduced bearing capacity, reduced bearing capacity of reinforcements, and inability to send skeletons, so as to improve the ability to resist outburst and increase the speed of safe coal excavation. , the effect of reducing the gas drain time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

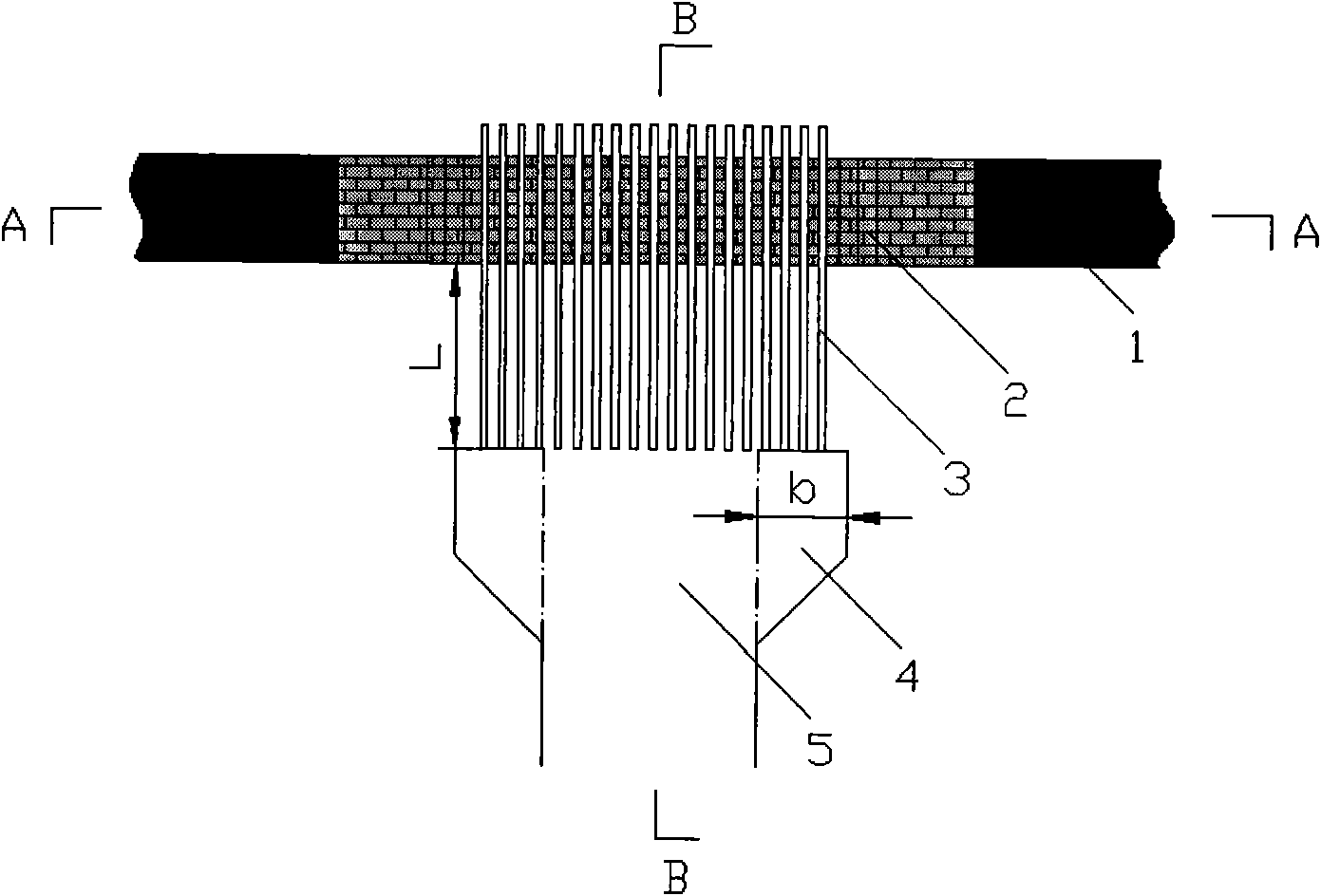

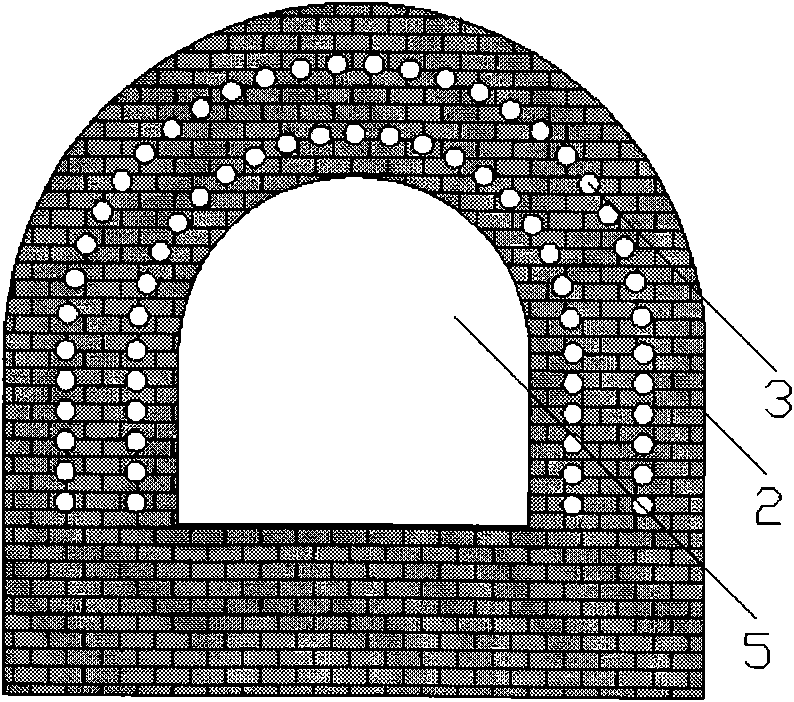

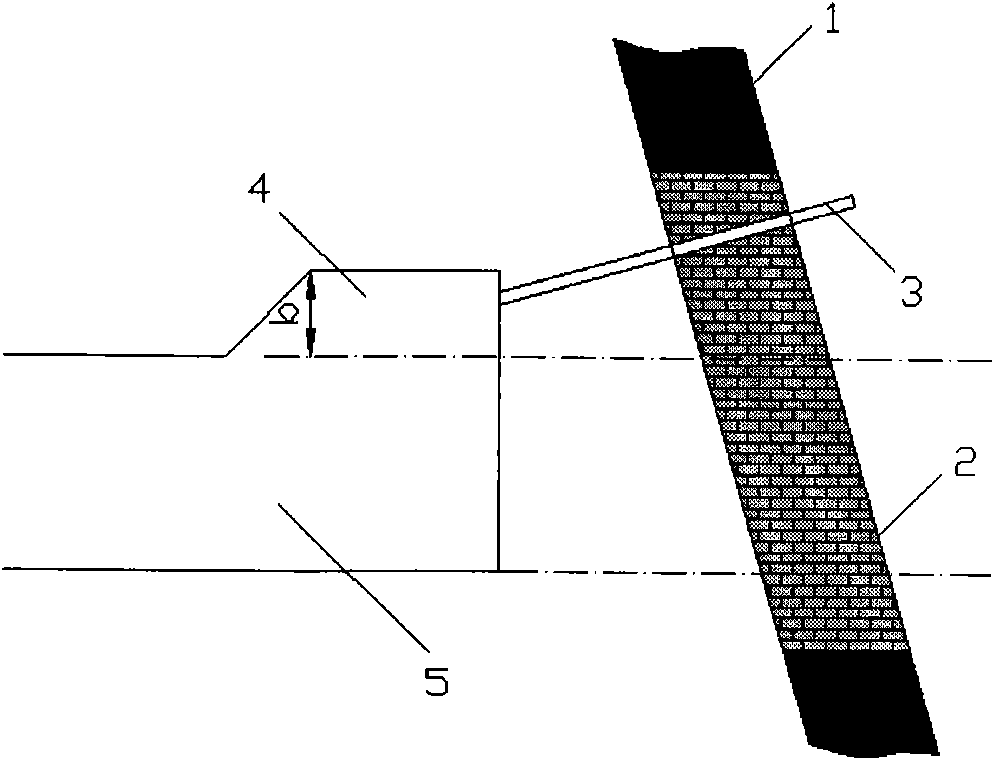

[0016] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

[0017] According to the geological conditions near the coal uncovering point provided by geological exploration, according to the coal seam thickness, inclination, direction, gas parameters, hydrological conditions, the direction and size of the roadway 5, and other factors during construction, the method for uncovering and reinforcing the stone door of the outburst dangerous coal seam according to the present invention If there are required parameters, formulate a detailed coal uncovering plan, do a good job of preparation before coal uncovering, and use conventional methods to deal with crack gas, water and other risk factors at the coal uncovering point to ensure that they will not affect the coal uncovering work. First, relieve the pressure on the coal and rock mass at the head of the roadway, measure the relevant parameters of the coal seam again ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com