Coal and firewood two purpose gas burning stove

A gas furnace and dual-purpose technology, which is applied in the field of coal and firewood dual-purpose gas furnaces, can solve the problems of inability to produce gas continuously, the inability of the steam-water separator to purify the gas source, and the impact on the thermal efficiency of the gas source, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

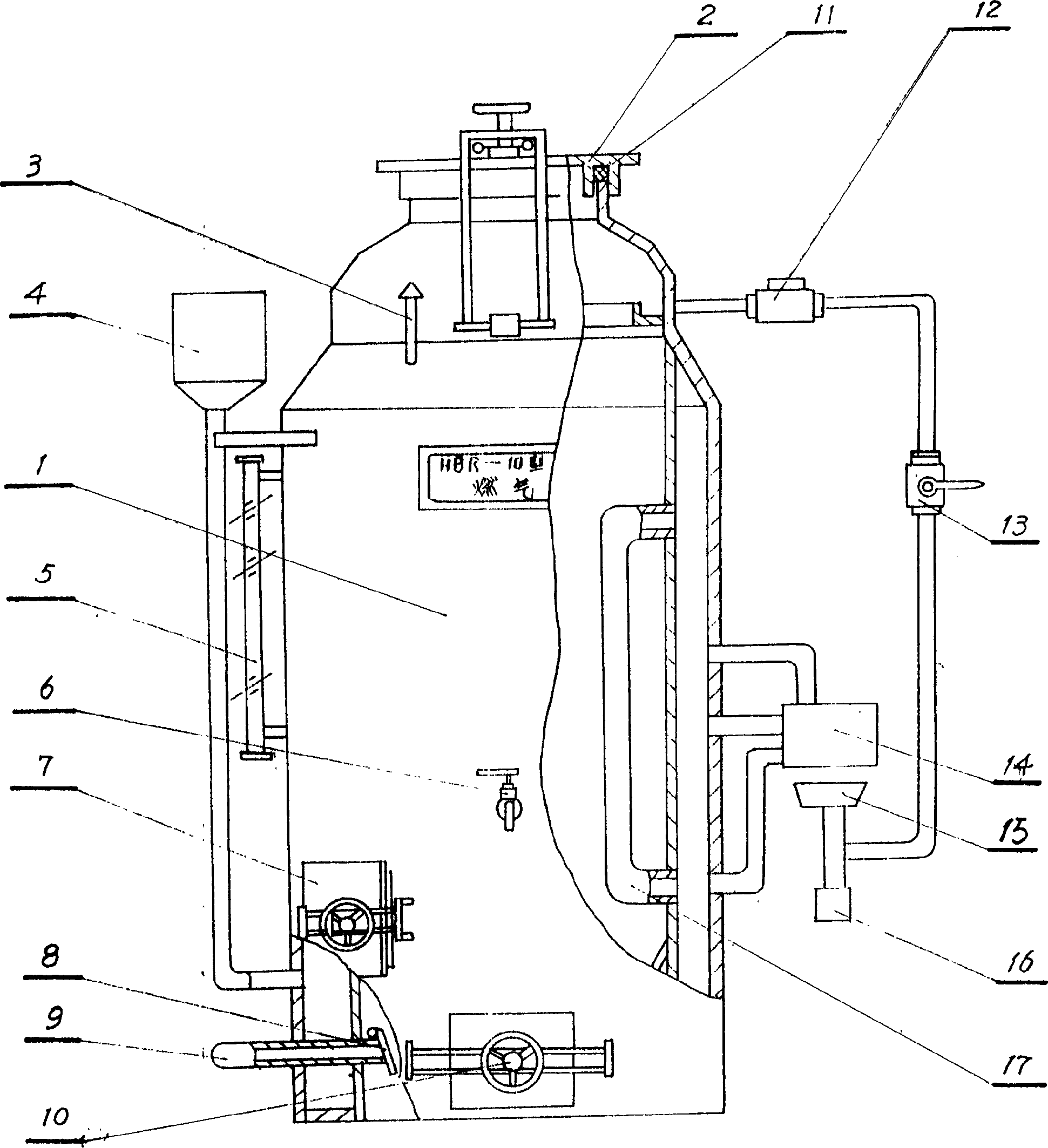

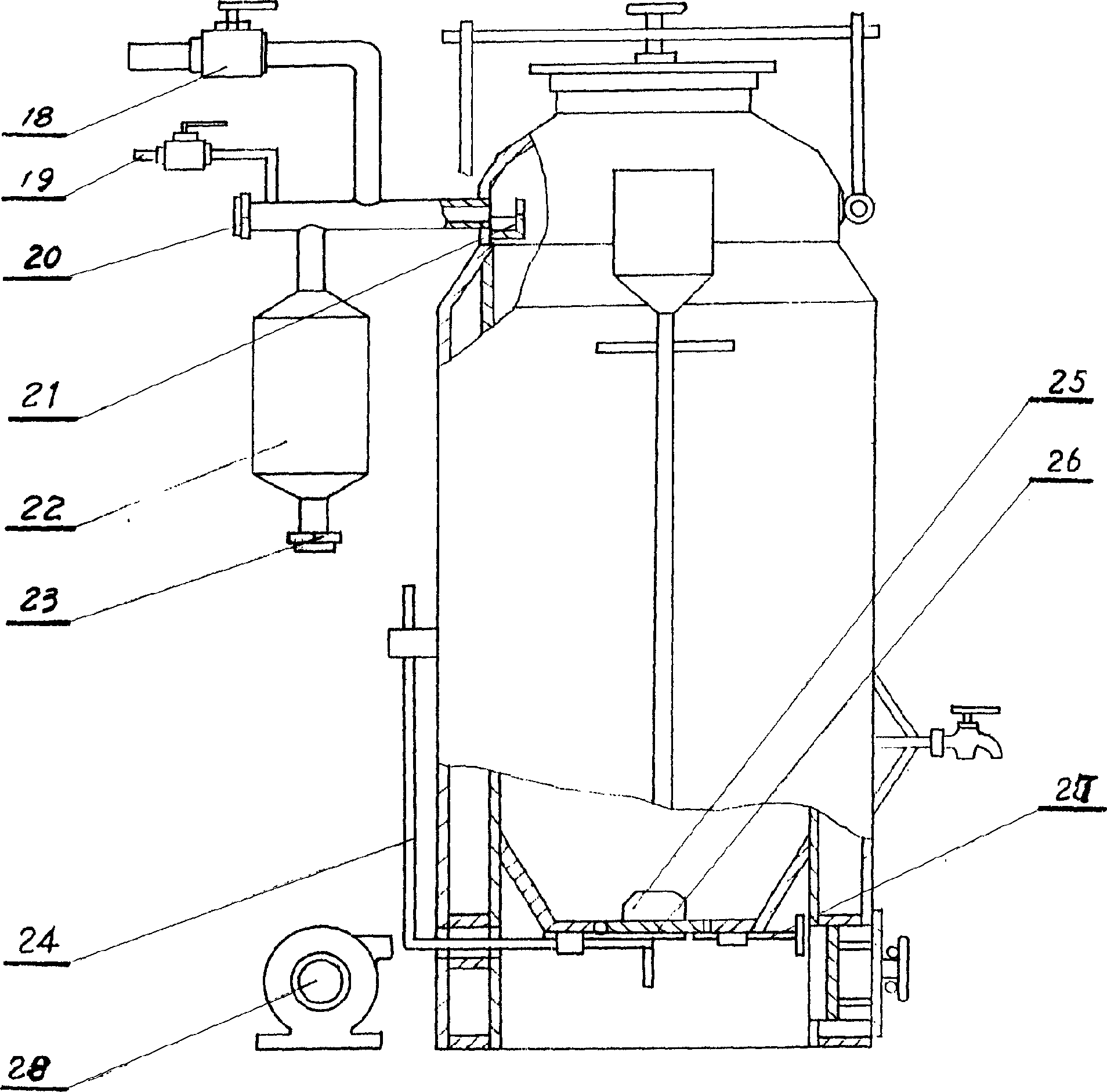

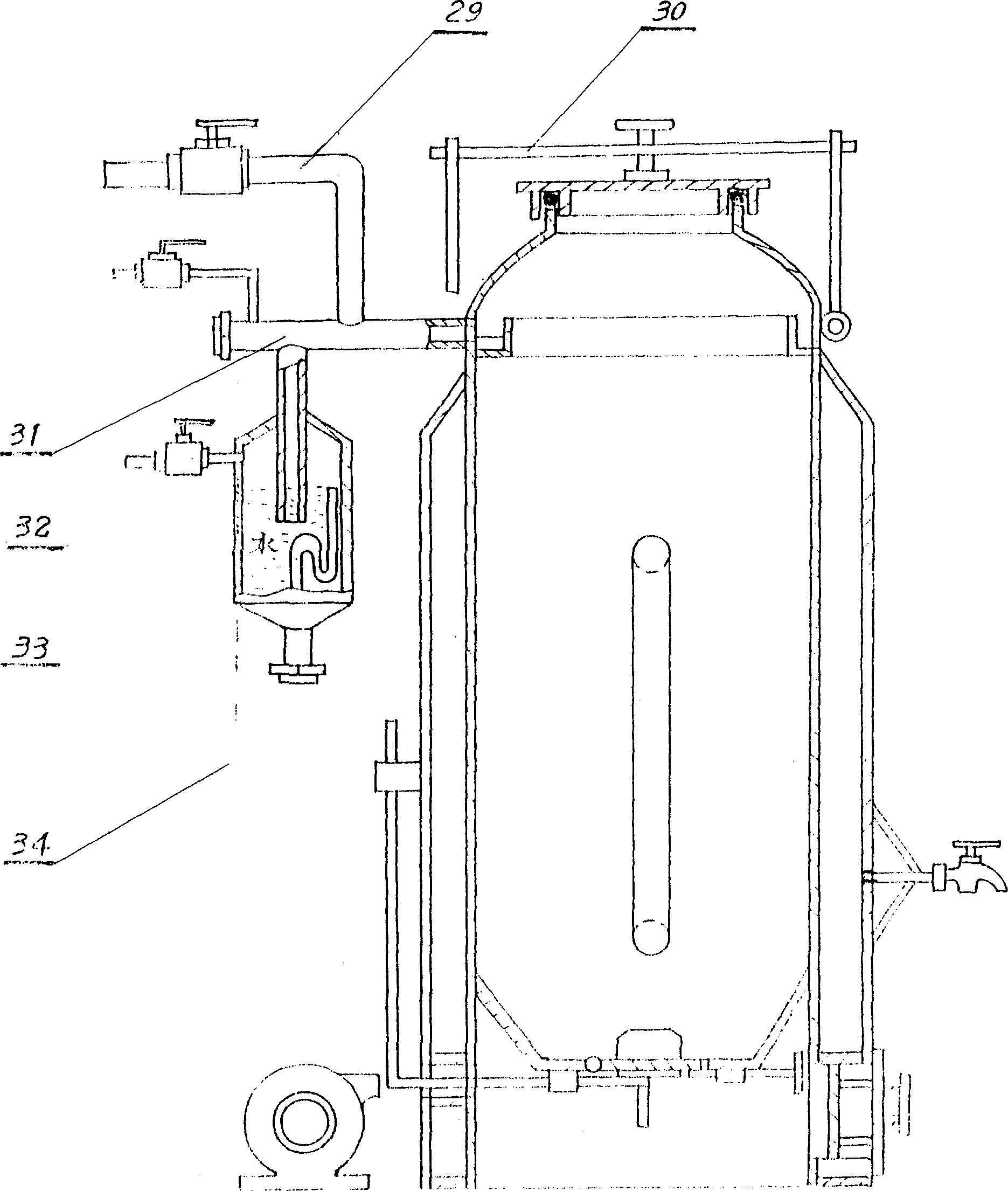

[0011] Refer to attached Figure 1-3 , open the upper cover locking device 30, the gland 2 is opened, place a igniter at the bottom of the furnace, then put in fuel, seal the upper cover locking device 30 on the gland 2 and the ash removal door 10, and ignite it at the coke removal door 7 Close the coke removal door 7 behind the igniter, open the smoke exhaust valve 18 simultaneously to make the blower fan 28 energized, introduce wind and pressurize through the air inlet 9, and the gas furnace produces gas after 7-9min. Now open the gas valve 13, ignite the burner 15 and close the smoke exhaust valve 18, heat the heater 14, and start heating. When the gas is produced for about 90-120 minutes, coking occurs due to the combustion of the fuel, and the top coke lever 24 is moved. Lift the generated coke to the upper part of the fuel so that the fuel can be in good contact with the primer, and then the gas can be produced continuously. During the gas production process, with the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com