Liquid fuel gasification combustor

A liquid fuel and burner technology, which is applied in the directions of burners, combustion methods, combustion types, etc., can solve problems such as restricting the use and promotion of alcohol-based fuels, insufficient fuel combustion, unstable combustion flame, etc., and achieve significant economic and social benefits. Benefit, fast heating, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

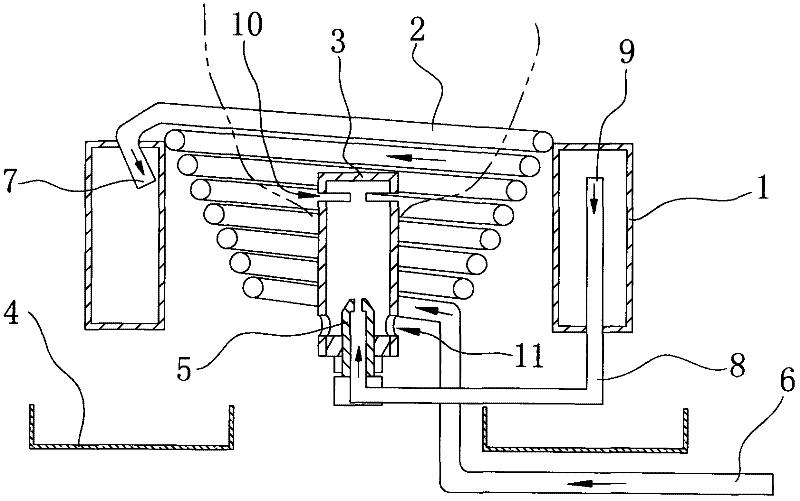

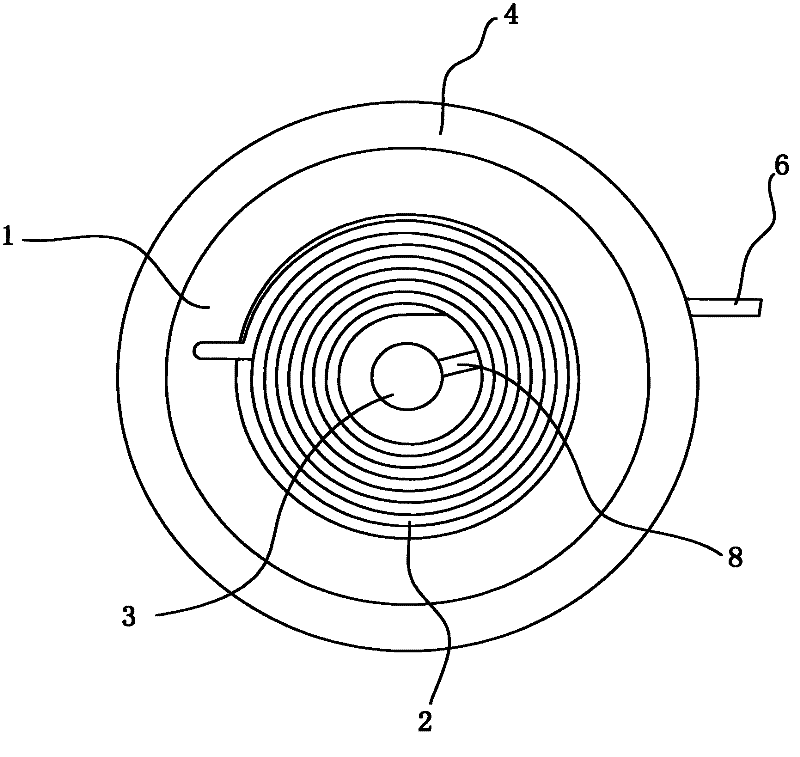

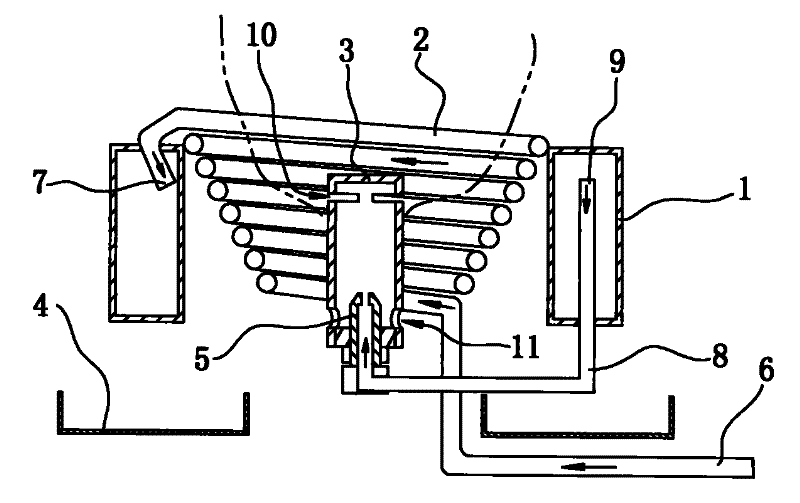

[0010] Such as figure 1 , 2 As shown, a liquid fuel burner includes a feed pipe 6 for supplying fuel and a nozzle 5 for ejecting fuel for combustion. The feed pipe 6 is connected to a fuel vaporizer, and the outlet 7 of the vaporizer is connected to gas-liquid separation The exhaust port of the gas-liquid separator is connected to the nozzle 5. Of course, the feed pipe 6 is also connected with a valve, even a feed pump and other mechanisms, and the connection technology and fixing technology of each component are well-known technologies, and will not be repeated.

[0011] The improvement of the present invention lies in the use of gasification and combustion, and at the same time a gas-liquid separator is provided to ensure the reliability of gasification; the two synergistically ensure the gasification effect and combustion efficiency. As for the nozzle 5 described in the prior art, it can be any nozzle that sprays gas, or a nozzle that functions as a spray or liquid; there are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com