Energy-saving fuel gas combustor

A burner and gas technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of incomplete combustion, harm to the health of chefs, uneven flames, etc., to reduce the cost of gas use and have excellent wind resistance. , adapt to a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

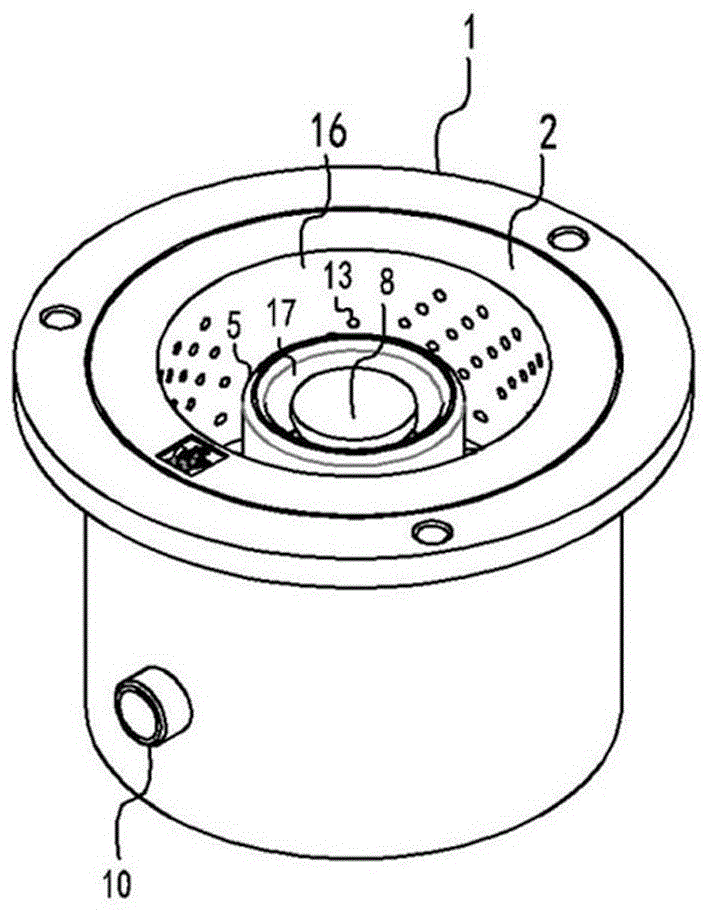

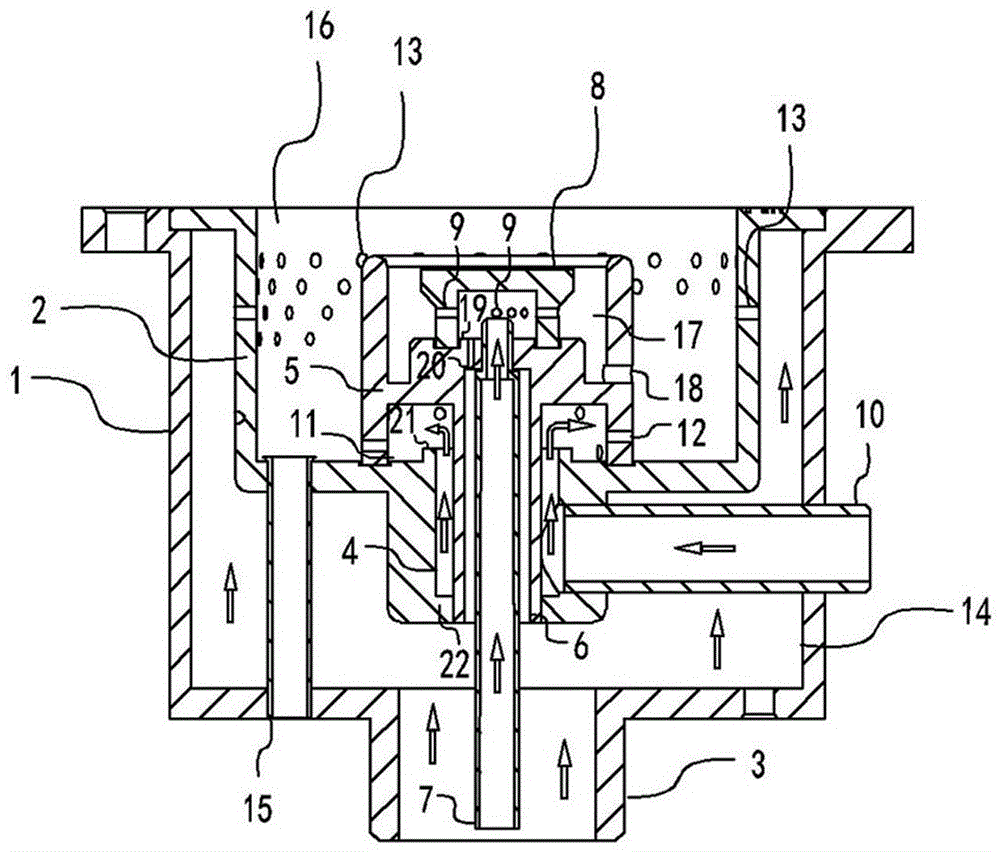

[0029] Such as Figure 1~3 As shown, the gas energy-saving burner includes an outer stove 1 and an inner stove 2; it is characterized in that the inner stove 2 is suspended in the outer stove 1; the bottom of the outer stove 1 is provided with a blower duct inlet 3; The bottom of the inner stove 2 is provided with an assembly channel opening 4; in the middle area of the inner stove 2 is provided a gas fire ring 5; the middle of the gas fire ring 5 is provided with a gas inlet channel 6; A small gas supply pipe 7 is arranged longitudinally in the air passage 6 and the blower duct inlet 3; a dust cap 8 is provided at the end of the small gas supply pipe 7; a dust cap 8 is provided on the side wall of the dust cap 8 Nozzle 9; a main gas inlet pipe 10 is fixed horizontally between the outer stove 1 and the inner stove 2; the ring between the air supply port of the main gas inlet pipe 10 and the gas inlet channel 6 and the assembly channel opening 4 The gas distribution cavity 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com