Biomass combined type gasification furnace

A compound gasification furnace technology, applied in coking ovens, household furnaces/stoves, special forms of dry distillation, etc., can solve problems such as easy to generate smoke, contain wood tar, unstable combustion, etc., and achieve stable performance and stable flame , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

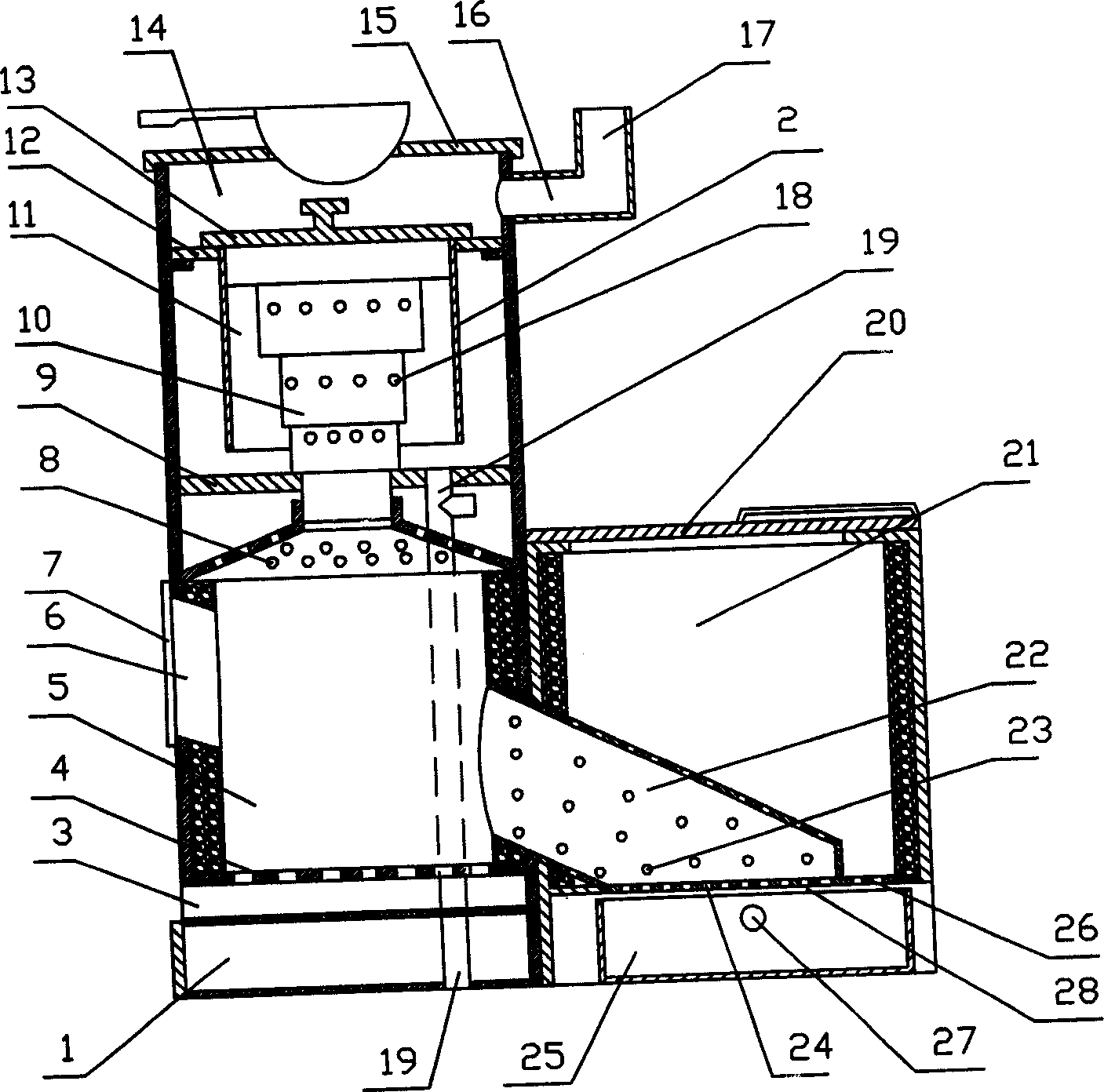

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] The biomass composite gasifier shown in the attached figure has a gas generator 21, a furnace hall 5, and a burner 2. The gas generator 21 is located at the side of the furnace hall 5 and is connected as a whole, and the burner 2 is installed in the furnace hall. 5 above and communicates with furnace hall 5. The gas-making box 21 and the inner wall of the furnace hall 5 have a heat-insulating and temperature-resistant layer, and the gas-making box 21 has a movable sealing cover 20. In the gas-making box 21, there is an oxidation combustion tube 22 arranged obliquely. The hall 5 is connected, and the lower end communicates with the ash bin 25 under the gas-making box 21, and the ash bin 25 communicates with the atmosphere. There is an air guide hole 23 on the oxidation combustion pipe 22, and the air guide hole 23 makes the gas making box 21 communicate with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com