Combustor and gas stove

A technology of burners and air vents, applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems of unfavorable gas stove cleaning design, high CO content in flue gas, and complex gas distribution plate structure, etc., to ensure Clean design, high cost, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

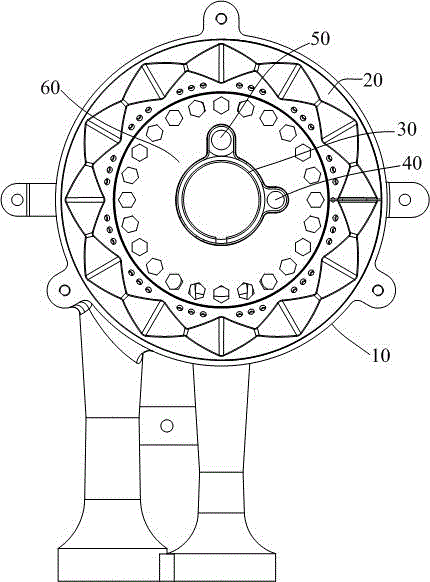

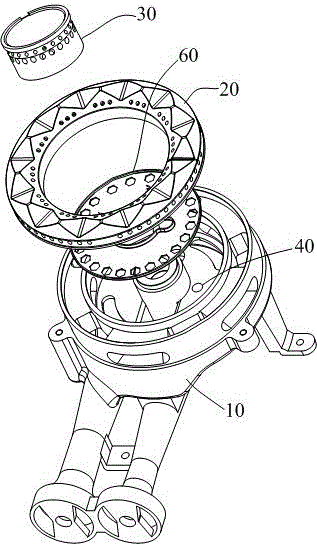

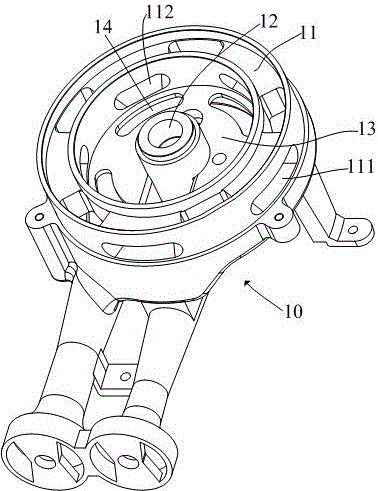

[0022] refer to Figure 1 to Figure 4 , a kind of burner, comprises furnace head 10, outer fire cover 20 and inner fire cover 30, burner head 10 comprises outer ring mixing chamber 11 and inner ring mixing chamber 12; Outer fire cover 20 is located on outer ring mixing chamber 11, and inner The fire cover 20 is located on the outer ring mixing chamber 11, and a vent hole 14 is arranged on the bottom wall of the passage area 13 between the outer ring mixing chamber 11 and the inner ring mixing chamber 12 on the burner head 10, and the vent hole 14 is connected with the burner head 10 below. The atmosphere in the channel area 13 is also provided with a cleaning dish 60. The cleaning dish 60 has a central through hole 61 for the inner ring mixing chamber 12, the thermocouple 40 of the burner and the ignition needle 50 to pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com