Abstergent of saving oil, gas and coal

A detergent and gas-saving technology, applied in the petroleum industry, liquid carbon-containing fuel, fuel, etc., can solve the problems of insufficient combustion of fuel, easy coking, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0007] Embodiment 1: Furnace heavy oil, residual oil, crude oil, shale crude oil, coal tar fuel-saving, gas-saving and coal-saving detergent is composed of the following components by weight: 95% to 99% of water, emulsifier SE-10 0.2~0.4%, emulsifier OJI-10 0.1~0.3%, emulsifier EL-40 0.3~0.6%, zinc naphthenate 0.4~0.5%, iron naphthenate 0.3~0.5%, ferrocene 0.3~0.6% , Pingping plus 0-9 0.3 ~ 0.5%.

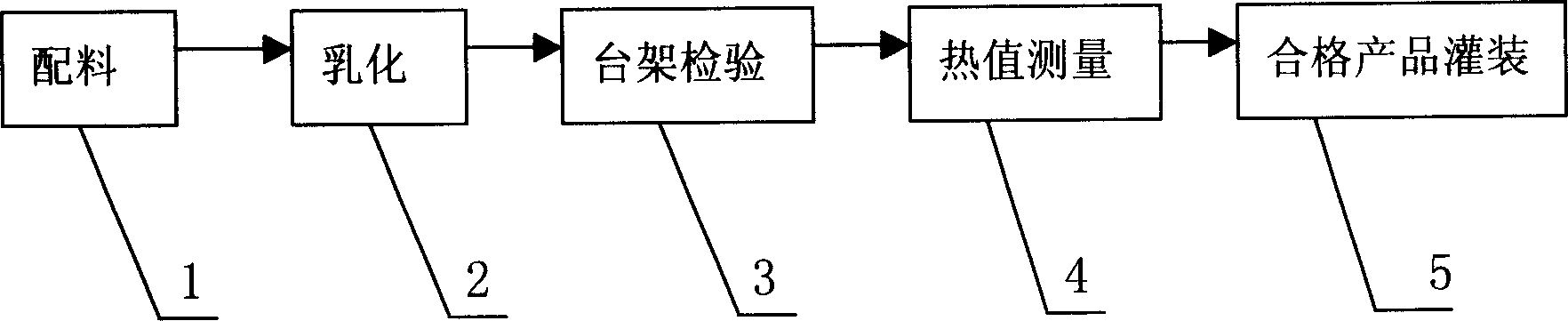

[0008] The process equipment of this agent is composed of: 1 mixer, 2 emulsifying machine, 3 gasoline and diesel engine stand, 4 calorific value measuring instrument, 5 filling machine.

[0009] Add water, zinc naphthenate, iron naphthenate, ferrocene, and Pingpingjia 0-9 to mixer 1 according to the formula ratio and stir for 30-40 minutes. After stirring fully, enter emulsifier 2 and add emulsifier SE-10, Agent OJI-10, emulsifier EL-40, emulsified for 10-12 hours at 25-40°C to make heavy oil, residual oil, crude oil, shale crude oil, coal tar oil-saving, gas-saving and coal-saving...

Embodiment 2

[0010] Embodiment 2: the formula of fuel-saving detergent for gasoline and diesel internal combustion engine, gasoline and diesel stove is: water 95~99%, emulsifier SE-10 0.2~0.4%, emulsifier OJI-10 0.1~0.3%, emulsifier EL- 40 0.3-0.6%, zinc naphthenate 0.4-0.5%, iron naphthenate 0.3-0.5%, ferrocene 0.3-0.6%, Pingpinga 0-9 0.3-0.5%.

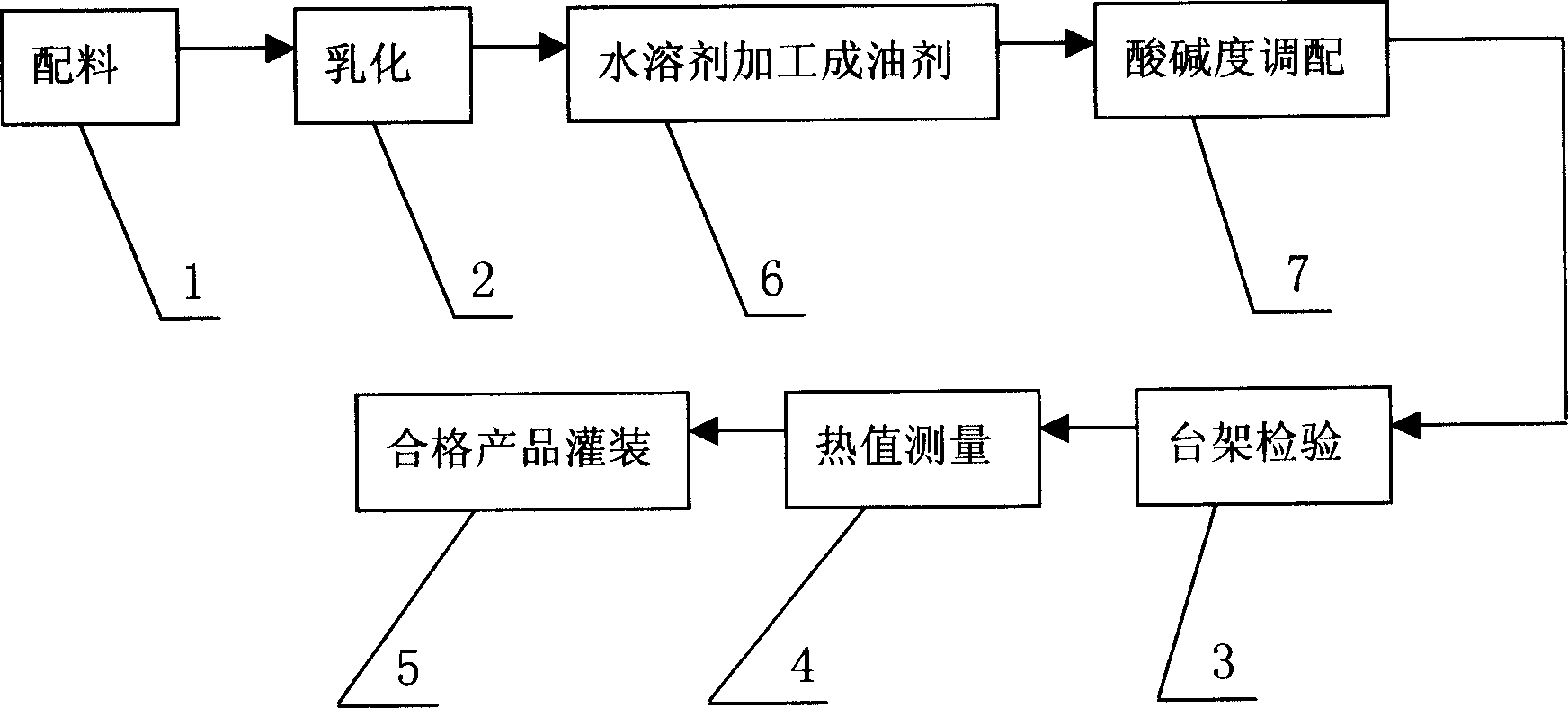

[0011] The process equipment of this agent is composed of: 1 mixer, 2 emulsifying machine, 3 gasoline and diesel engine stand, 4 calorific value measuring instrument, 5 filling machine, 6 oil mixing machine, 7 acid-base meter.

[0012] Add water, zinc naphthenate, iron naphthenate, ferrocene, and Pingpingjia 0-9 to mixer 1 according to the formula ratio and stir for 30-40 minutes. After stirring fully, enter emulsifier 2 and add emulsifier SE-10, Agent OJI-10, emulsifier EL-40, emulsified for 10-12 hours at 25-40°C to make heavy oil, residual oil, crude oil, shale crude oil, coal tar oil-saving, gas-saving and coal-saving detergents for furnaces,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com