Special furnace end for alcohol base liquid fuel

A liquid fuel, burner technology, applied in the burner, combustion method, combustion type and other directions, can solve problems such as low thermal efficiency, and achieve the effects of improved thermal efficiency, sufficient combustion, and uniform wind distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

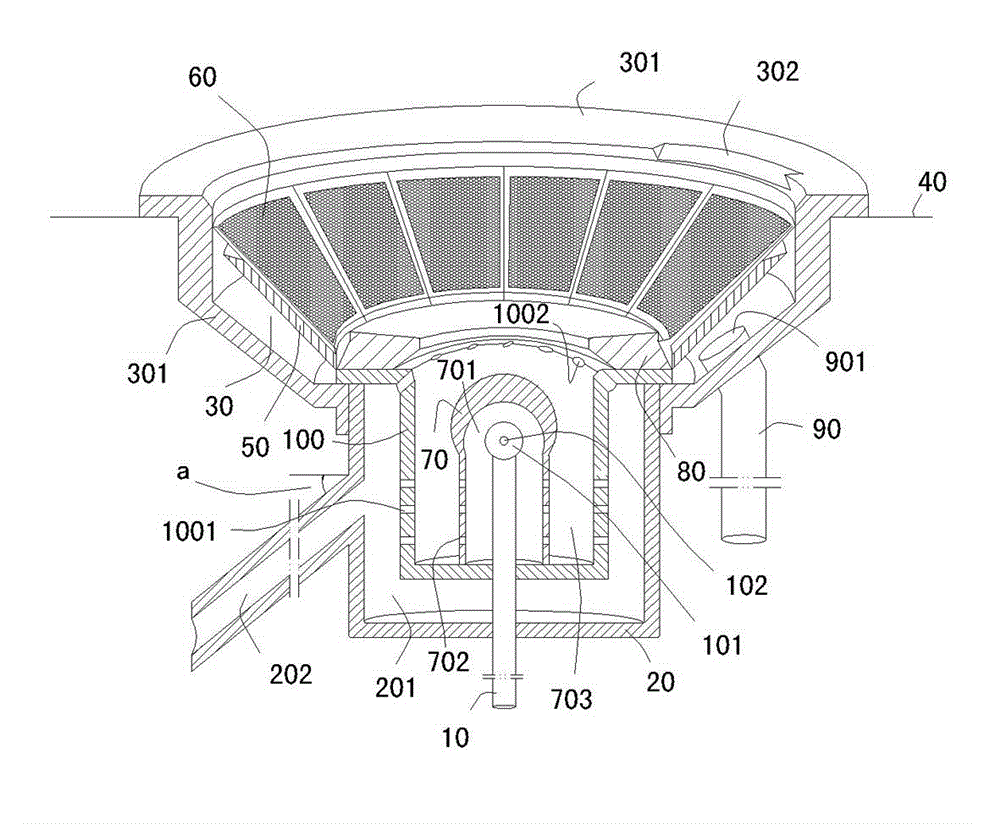

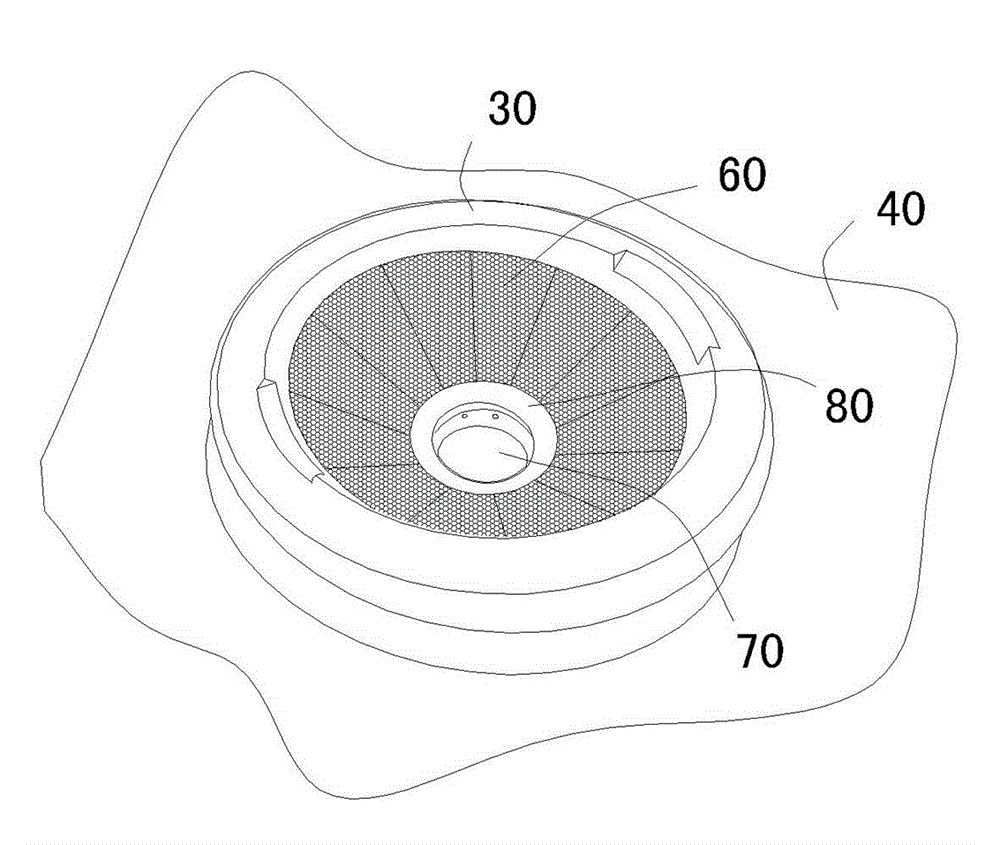

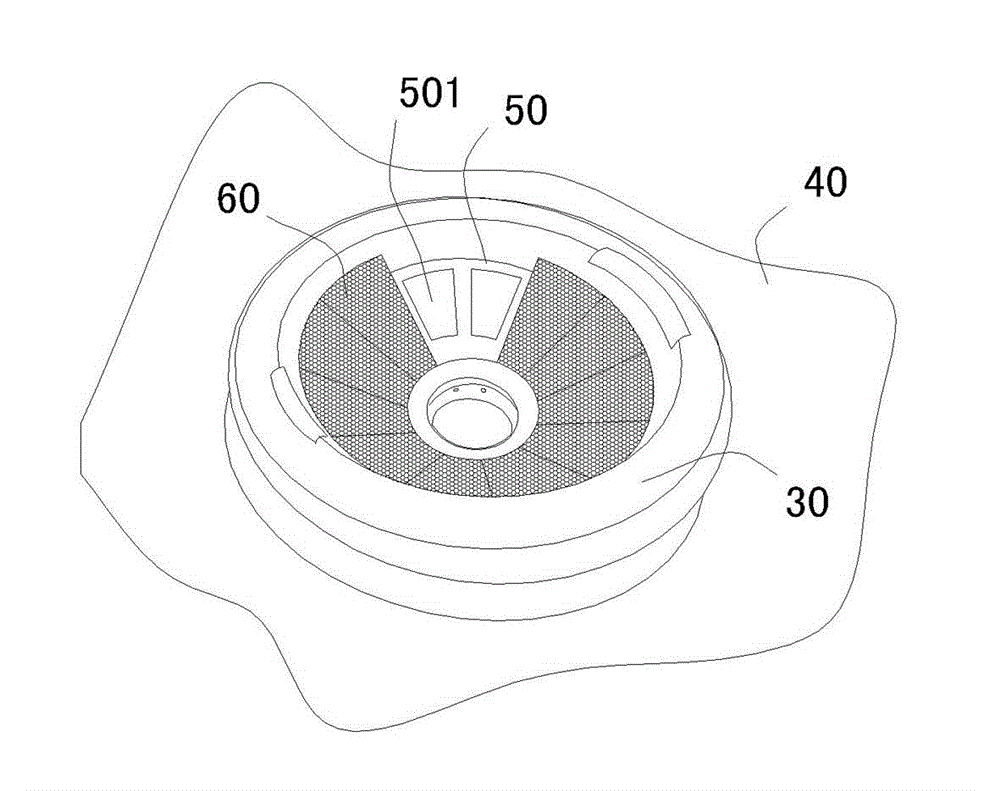

[0020] see figure 1 . The burner structure of the present invention includes an oil inlet pipe 10 , a vaporization head 70 , a combustion bowl 100 , an air inlet bowl 20 , a furnace wall 301 , an air inlet pipe 202 and an air outlet pipe 90 from bottom to top. The air inlet bowl 20 and the combustion bowl 100 are respectively two circular cylinders with different diameters which are hermetically sealed together. The vaporizing head 70 is accommodated in the middle of the inner cavity of the combustion bowl 100, and its top is a spherical closed body, and a plurality of sidewall holes 702 are opened on the body of the barrel, serving as steam outlets for the vaporized liquid. The oil inlet pipe 10 vertically extends through the bottom wall of the air inlet bowl 20 and the combustion bowl 100 , and the end reaches the upper part of the inner cavity of the vaporizing head 70 , and an oil nozzle 102 is set on the oil injection head 101 . A combustion chamber 703 is formed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com