Lightweighting pure electric automobile body and design method thereof

A pure electric vehicle, lightweight technology, applied in computing, vehicle components, electrical digital data processing and other directions, can solve the problem of unreasonable design of battery pack structure, battery pack fixed structure, can not meet the performance requirements of high-speed electric vehicles, body weight reduction body Low contribution to structural strength and other issues, to achieve the effect of improving functional integration, low cost, and reducing the number of parts and welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

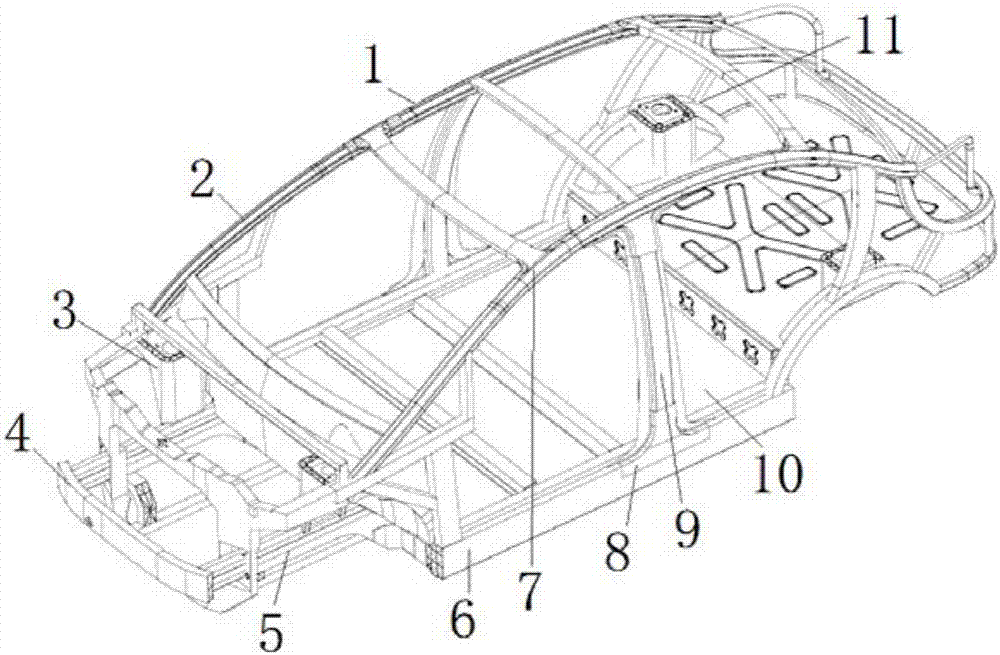

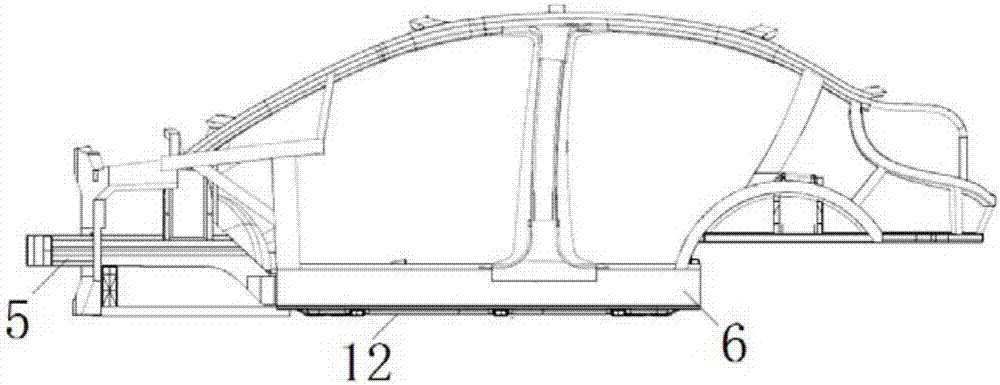

[0041] Such as Figure 1 to Figure 6 As shown, the lightweight body of the pure electric vehicle includes a body frame 1 and a battery pack frame. The body frame 1 is provided with an outer cover, a fender, a body floor 10, front and rear bumper structures, and an energy-absorbing structure. The frame and battery pack frame are all aluminum alloy profile space frame structures, and the outer panels, fenders, body floors, front and rear bumper structures, and energy-absorbing structures are all made of carbon fiber composite materials.

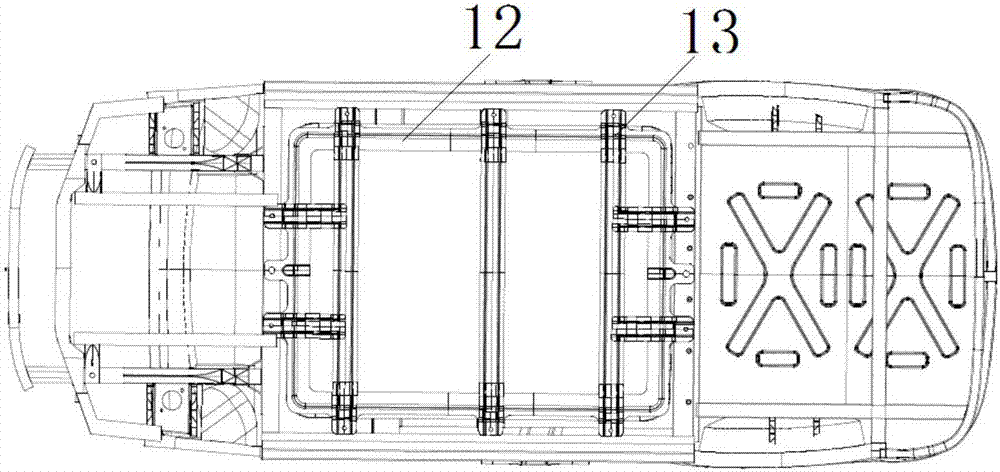

[0042] The battery pack frame is located under the vehicle body floor 10. The battery pack frame includes a battery pack housing and a battery pack fixing frame plate 13 arranged under the battery pack housing. The edges of the battery pack fixing frame plate 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com