LED display screen

A technology of LED display and display screen, applied in the direction of instruments, identification devices, etc., can solve the problems of inability to meet the structure, high precision requirements, insufficient stability, etc., and achieve the effects of convenient debugging, good heat dissipation and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

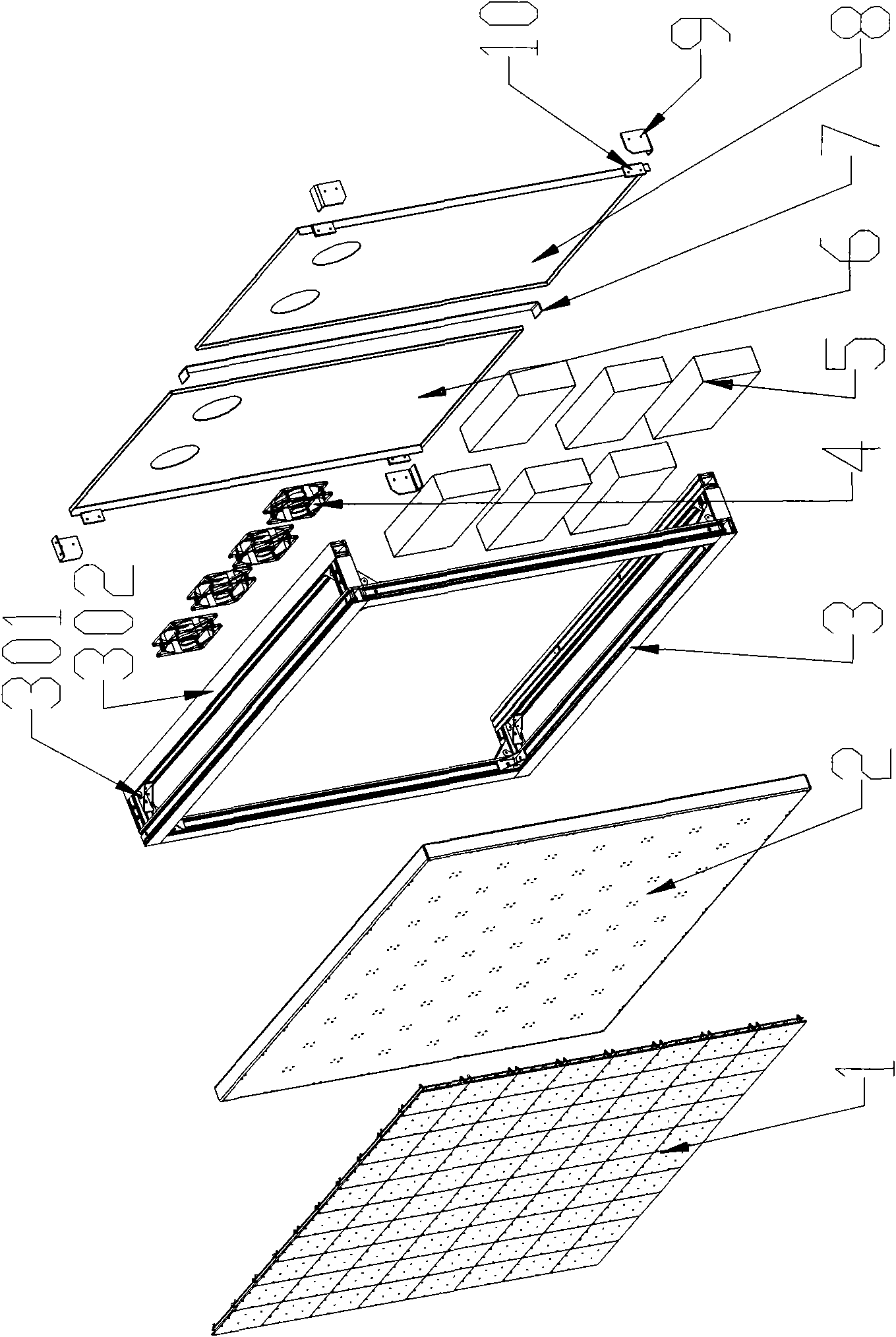

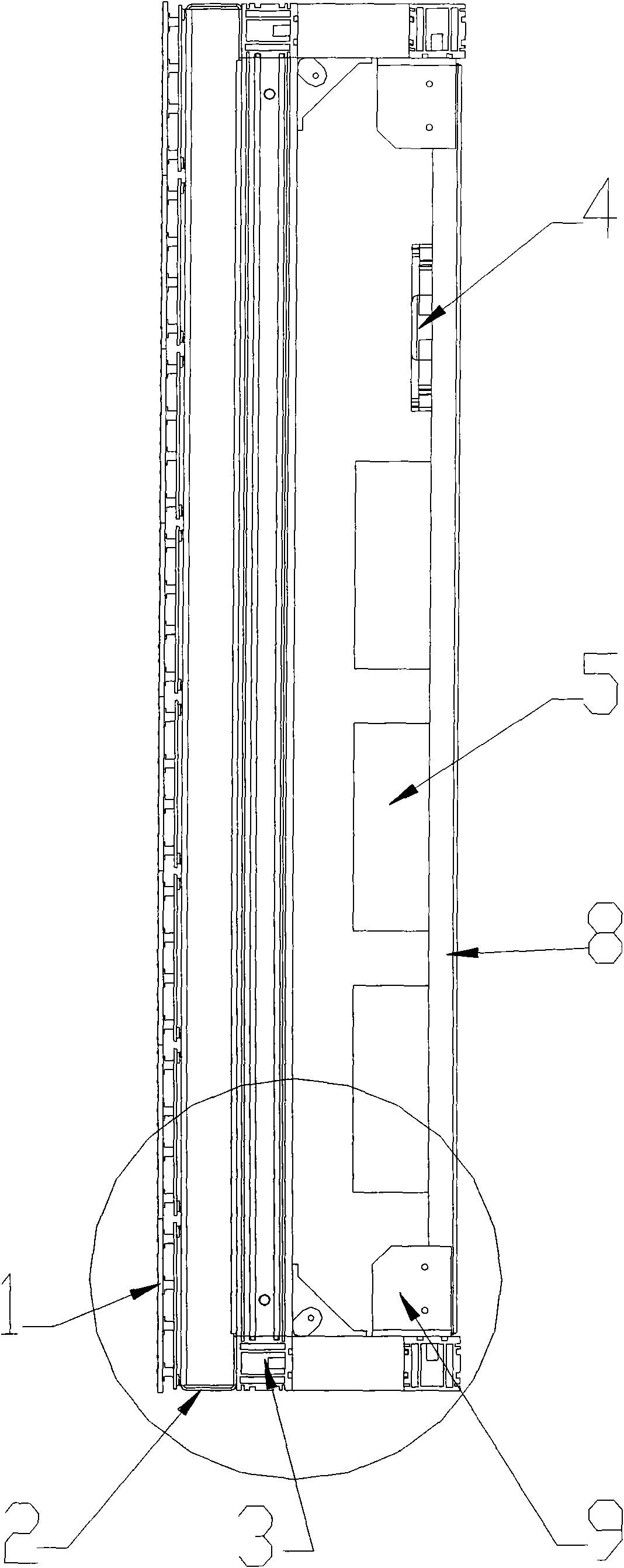

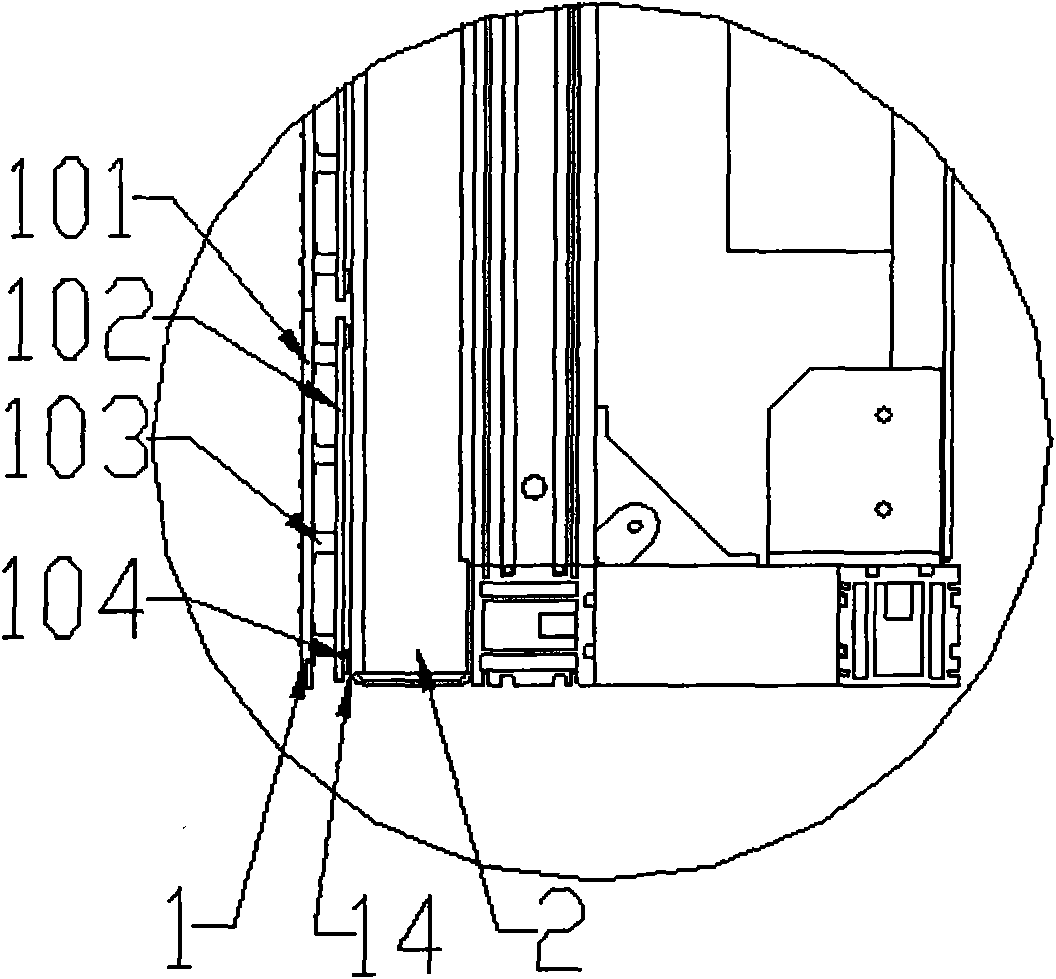

[0044] An LED display screen is composed of several display screen units spliced through a display screen mounting frame 15. The display screen unit includes a display module, a display screen box 3, a heat dissipation device and a connecting device, and the display module is connected to the The display cabinets 3 are connected to each other, and the display cabinets 3 are connected to the cooling device through a connection device; the connection device includes rivets, pins, screws or bolts.

[0045] The display screen box 3 is a three-dimensional frame structure composed of 10 mutually perpendicular brackets. Angle code 301 is used to fix the bracket parts, and the bracket parts are connected by threaded connection. The support member is a hollow profile.

[0046]The display screen box 3 is a three-dimensional frame structure composed of 10 mutually perpendicular brackets, specifically consisting of 4 horizontally long brackets, 2 vertically long brackets and 4 short br...

Embodiment 2

[0054] An LED display screen is composed of several display screen units spliced through a display screen mounting frame 15. The display screen unit includes a display module, a display screen box 3, a heat dissipation device and a connecting device, and the display module is connected to the The display case 3 is connected, and the display case 3 is connected with the heat dissipation device through a connecting device, and the connecting device includes a rivet, a bolt, a screw or a bolt.

[0055] The display screen box 3 is a three-dimensional frame structure composed of 10 mutually perpendicular brackets. Angle code 301 is used to fix the bracket parts, and the bracket parts are connected by threaded connection. The bracket is an L-shaped profile.

[0056] The display screen box 3 is a three-dimensional frame structure composed of 10 mutually perpendicular brackets, specifically consisting of 4 horizontally long brackets, 2 vertically long brackets and 4 short brackets,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com