Projection exposure device and splicing method

An exposure device and projection technology, applied in the field of lithography, can solve the problems of high requirements for splicing images, displacement of one image point, distortion of projected images, etc., and achieve the effect of improving exposure quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

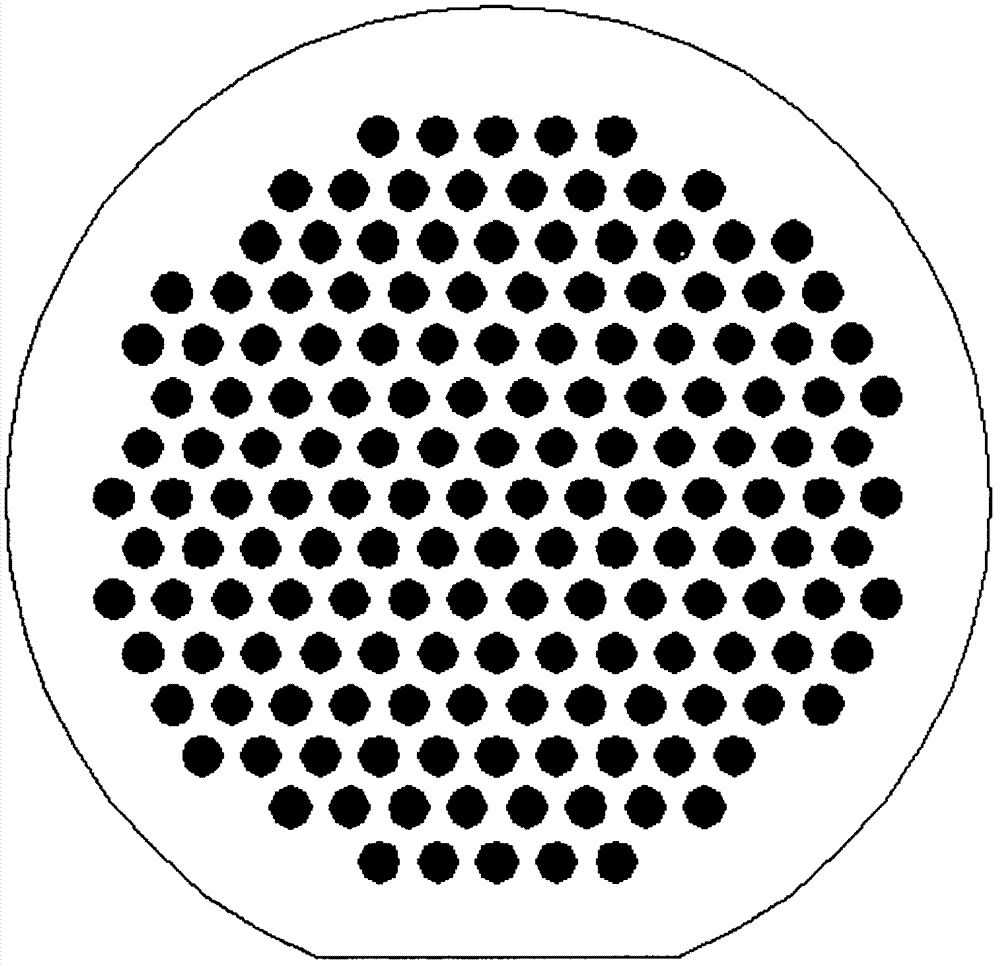

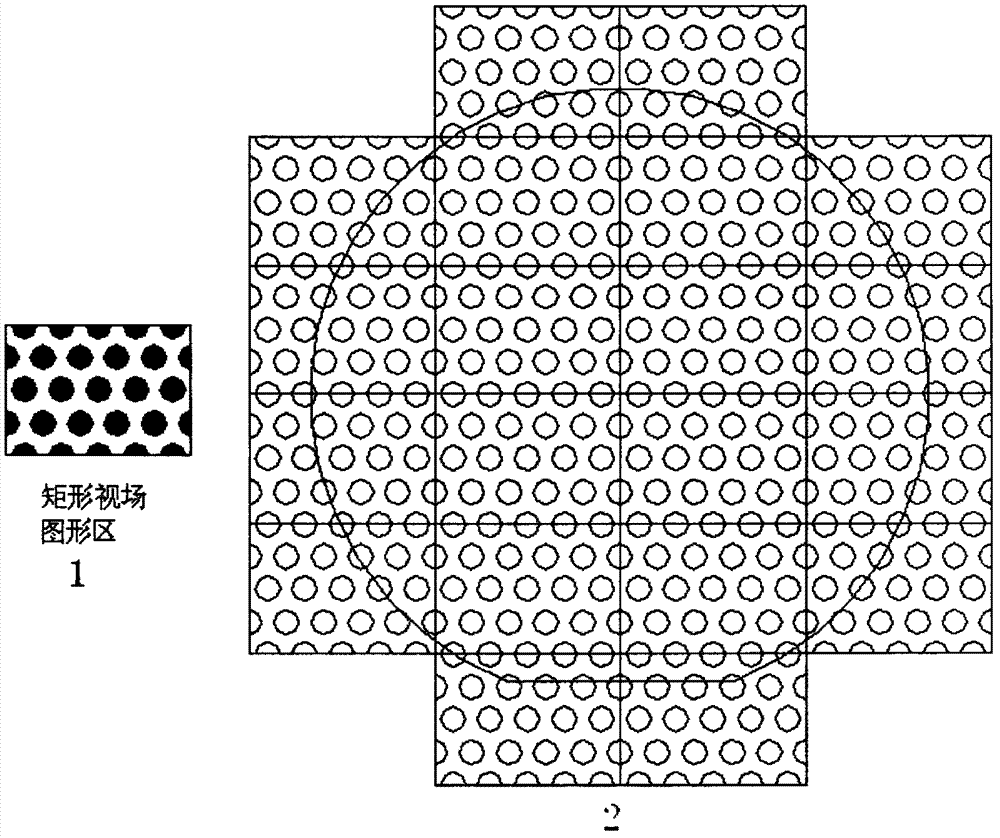

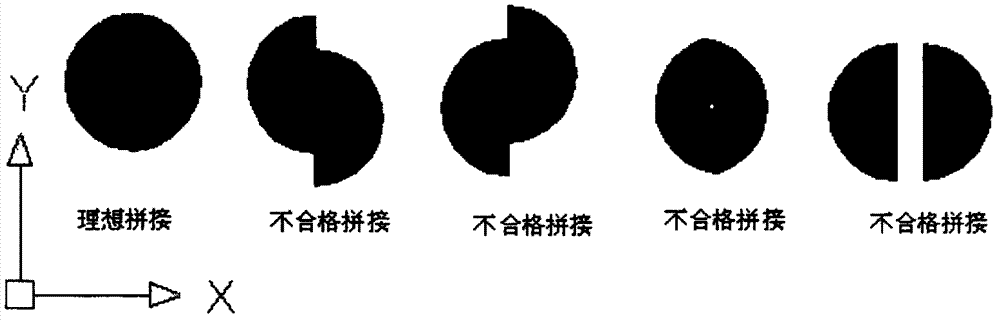

[0049] In this embodiment, the sapphire material with a diameter of 50 mm is used as the substrate, and the exposed circular patterns need to be arranged in a diamond shape. The diameter of the pattern is 2 microns, and the pattern spacing is 1 micron. The schematic diagram of the arrangement is as follows Figure 9 shown. The initial state of the four blades is as follows Figure 6 shown. Rotate the knife edges 9 and 11 clockwise by 30 degrees each, so that the stitching line between the fields of view does not pass through the graphics area, and the diamond-shaped field of view is as follows Figure 9 As shown, all four sides of the field of view are 0.5 μm from the edge of the graph. The action steps to form the diamond-shaped field of view are:

[0050] 1. First, the 9 blades are rotated 30 degrees clockwise with the upper left corner as the origin;

[0051] 2. Then the 11 knife edge is rotated 30 degrees clockwise with the upper right corner as the origin;

[0052] 3...

no. 2 approach

[0066] Figure 16 Shown is the exposure schematic diagram of the stepper photolithography machine adopting two kinds of fields of view: equilateral triangle field of view and trapezoidal field of view according to the present invention. The formation methods of equilateral triangular field of view and trapezoidal field of view are similar to the formation of prismatic field of view in Example 1. The use of these two non-rectangular fields of view can also avoid the pattern being divided by splicing lines, and its movement mode is similar to that of traditional stepping Lithography machines are the same. As shown in 20 , the triangular field of view first exposes area 1 on the substrate field by field, and then rotates the substrate 180 degrees horizontally, and then exposes area 2 on the substrate field by field. The trapezoidal field of view used in 21 is similar to the equilateral triangle field of view. First, the area 1 on the substrate is exposed field by field, and then...

no. 3 approach

[0075] The third method of the present invention is to adopt traditional methods such as Figure 6 For the rectangular field of view shown, the mask shape is made as Figure 9 or Figure 12 the rhombus shown or Figure 14 For non-rectangular shapes such as triangles shown, when the mask shape is made into a rhombus, the movement of the workbench of the lithography machine is as follows figure 2 Shown is similar to Example 1. Its workflow is:

[0076] 1. Put the mask into the mask holder through the transmission system;

[0077] 2. Transfer the 4-inch sapphire substrate to the top of the workpiece table, put it down, start the vacuum adsorption, and adsorb the substrate on the vacuum suction cup;

[0078] 3. According to the shape of the field of view, such as Figure 12 In the step-by-step recipe shown, the workpiece table is moved to move the desired exposure area of the substrate to the bottom of the mask and expose each field of view one by one.

[0079] Figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com