Preparation method of lithium ion battery electrolyte corrosion resisting double-component epoxy adhesive

A lithium-ion battery, epoxy adhesive technology, applied in the direction of adhesives, epoxy resin adhesives, non-polymer adhesive additives, etc. Strength, the effect of meeting diverse needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

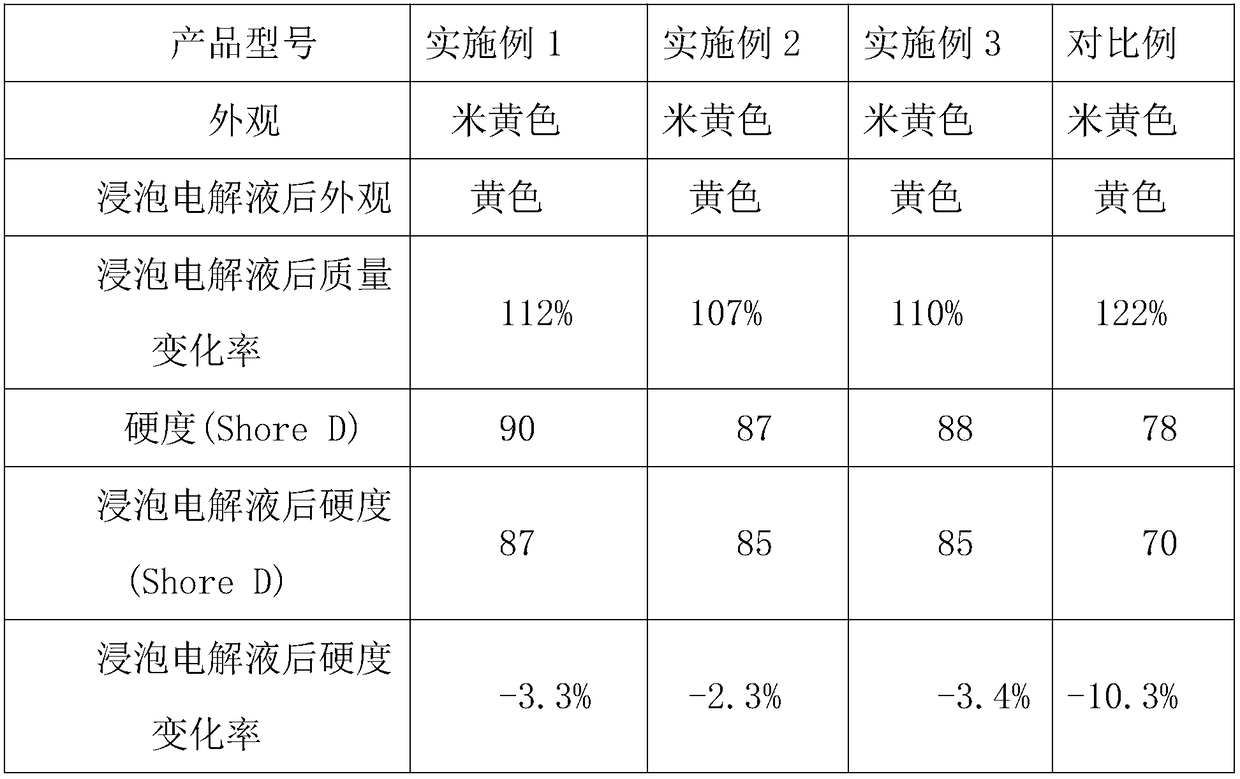

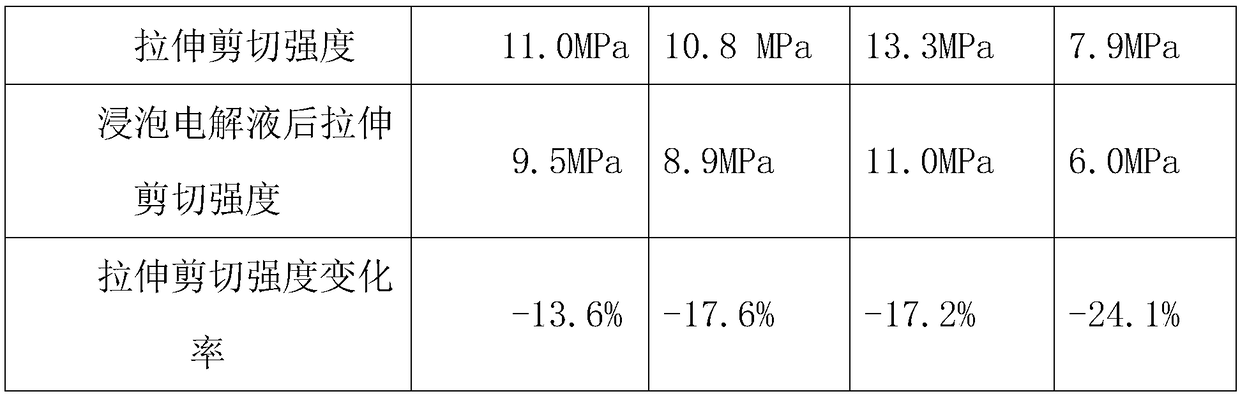

Examples

Embodiment 1

[0038] (1) In the planetary stirring tank, add 45 parts by mass of E51 epoxy resin, 30 parts by mass of polyurethane modified epoxy resin (self-made), γ-(2,3-glycidoxy) propyltrimethoxysilane 1.5 parts by mass, 3.6 parts by mass of 1,4-butanediol diglycidyl ether, stirred at 45 rpm for 10 min.

[0039] (2) Add 22 parts by mass of active calcium carbonate, stir and disperse at a vacuum degree of 0.090Mpa at a stirring speed of 45rpm and a dispersing speed of 2000rpm to obtain component A.

[0040] (3) In the planetary stirring tank, add 60 parts by mass of modified amine curing agent, 5 parts by mass of aliphatic amine curing agent, 1 part by mass of imidazole curing agent, 2,4,6-tris(dimethylaminomethyl ) 1.5 parts by mass of phenol, stirred at 45 rpm for 10 min.

[0041] (4) Add 35 parts by mass of active calcium carbonate, stir and disperse at a vacuum degree of 0.090 Mpa at a stirring speed of 45 rpm and a dispersing speed of 2000 rpm to obtain component B.

[0042] (5) M...

Embodiment 2

[0044] (1) In the planetary stirring tank, add 30 parts by mass of E51 epoxy resin, 40 parts by mass of polyurethane modified epoxy resin (self-made), γ-(2,3-epoxypropoxy)propyltrimethoxysilane 1 part by mass, 2 parts by mass of 1,4-butanediol diglycidyl ether, stirred at 45 rpm for 10 min.

[0045] (2) Add 15 parts by mass of active calcium carbonate, stir and disperse at a vacuum degree of 0.090 Mpa at a stirring speed of 45 rpm and a dispersion speed of 2000 rpm to obtain component A.

[0046] (3) Add 50 parts by mass of a modified amine curing agent, 2 parts by mass of an aliphatic amine curing agent, and 1 part by mass of 2,4,6-tris(dimethylaminomethyl)phenol, and stir at 45 rpm for 10 minutes.

[0047] (4) Add 20 parts by mass of active calcium carbonate, stir and disperse at a vacuum degree of 0.090 Mpa at a stirring speed of 45 rpm and a dispersion speed of 2000 rpm to obtain component B.

[0048] (5) Mix the above-mentioned components A and B at room temperature with...

Embodiment 3

[0050] (1) Add 50 parts by mass of E51 epoxy resin, 20 parts by mass of polyurethane modified epoxy resin (self-made), 4 parts by mass of γ-(2,3-epoxypropoxy)propyltrimethoxysilane, 1, 8 mass parts of 4-butanediol diglycidyl ether were stirred at 45 rpm for 10 min.

[0051] (2) Add 35 parts by mass of active calcium carbonate, stir and disperse at a vacuum degree of 0.090 Mpa at a stirring speed of 45 rpm and a dispersion speed of 2000 rpm to obtain component A.

[0052] (3) Add 70 parts by mass of a modified amine curing agent, 8 parts by mass of an aliphatic amine curing agent, 2 parts by mass of an imidazole curing agent, and 3 parts by mass of 2,4,6-tris(dimethylaminomethyl)phenol, Stir at 45rpm for 10min.

[0053] (4) Add 40 parts by mass of active calcium carbonate, stir and disperse at a vacuum degree of 0.090 Mpa at a stirring speed of 45 rpm and a dispersion speed of 2000 rpm to obtain component B.

[0054] (5) Mix the above-mentioned components A and B at room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com