Hot backup dual-redundancy electro-hydraulic servo valve control system based on pipeline fluid parameter design

An electro-hydraulic servo valve and fluid parameter technology, which is applied to fluid pressure actuation system components, mechanical equipment, servo motor components, etc., can solve problems such as the inability to independently manufacture hot backup double-redundant electro-hydraulic servo valves, and reduce development Cost and risk, improve system reliability, shorten the effect of development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

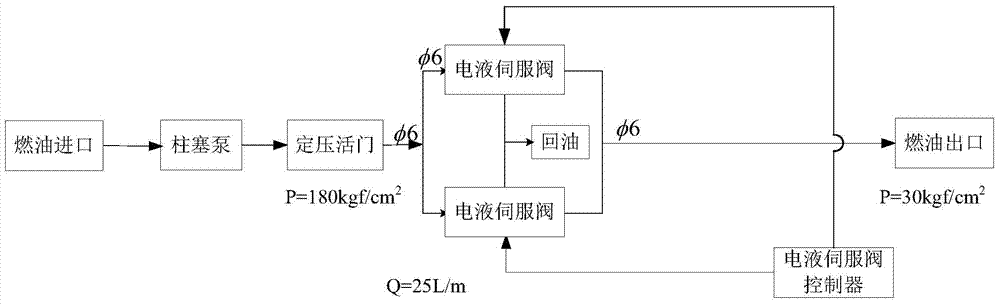

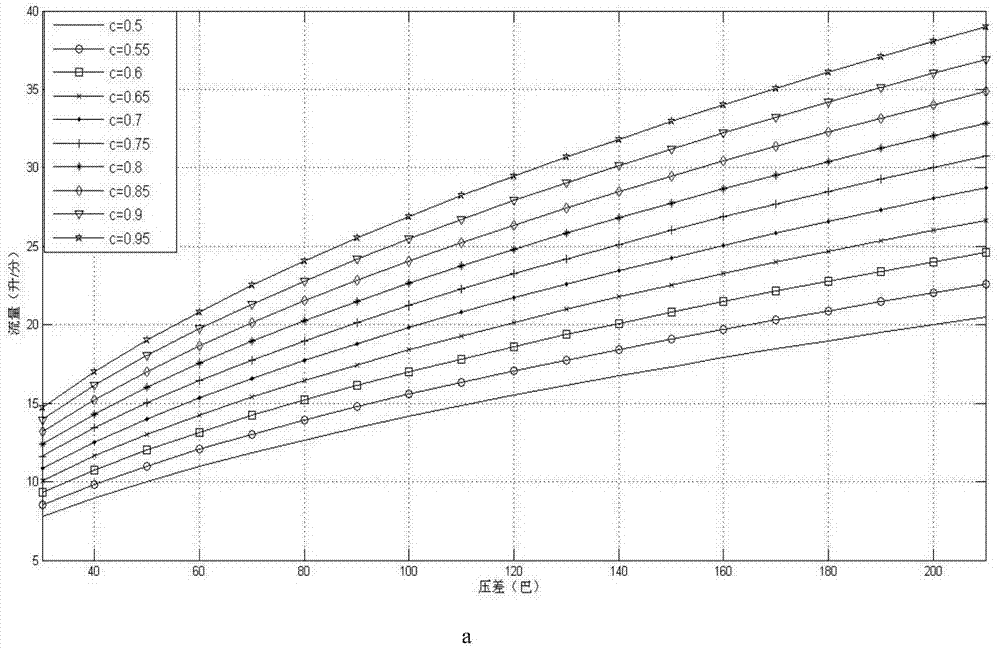

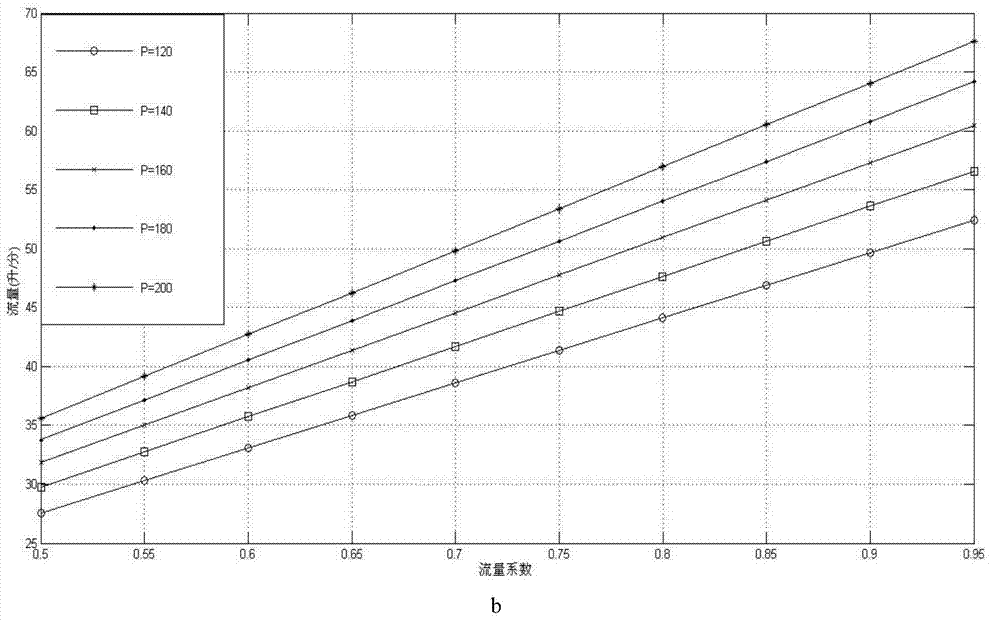

[0027] Taking the fuel supply system of a certain type of aeroengine as an example, to ensure that the engine works at a state where the high-pressure rotor speed is ≥85%, the required fuel flow rate should be ≥25L / min. according to figure 1 Design the system structure, in which the working pressure of the fuel oil at the inlet of the electro-hydraulic servo valve is 17~21Mpa, the outlet pressure of the fuel oil (that is, the pressure of the combustion chamber)≯3Mpa, the corresponding pressure difference between the inlet and outlet is 14~18Mpa, and the pipe diameter of the fuel system is Ф6.

[0028] This embodiment includes a plunger pump, a constant pressure valve, an adapter block inlet pipe diameter and an outlet pipe diameter matching the pipeline flow parameters, and a double-redundancy electro-hydraulic servo valve; the output end of the double-redundancy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com