Patents

Literature

32results about How to "Avoid flash explosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based high-temperature-resistant anti-corrosion composition

PendingCN112831252AImprove anti-corrosion performanceImprove performanceFireproof paintsAntifouling/underwater paintsAdhesive cementMischmetal

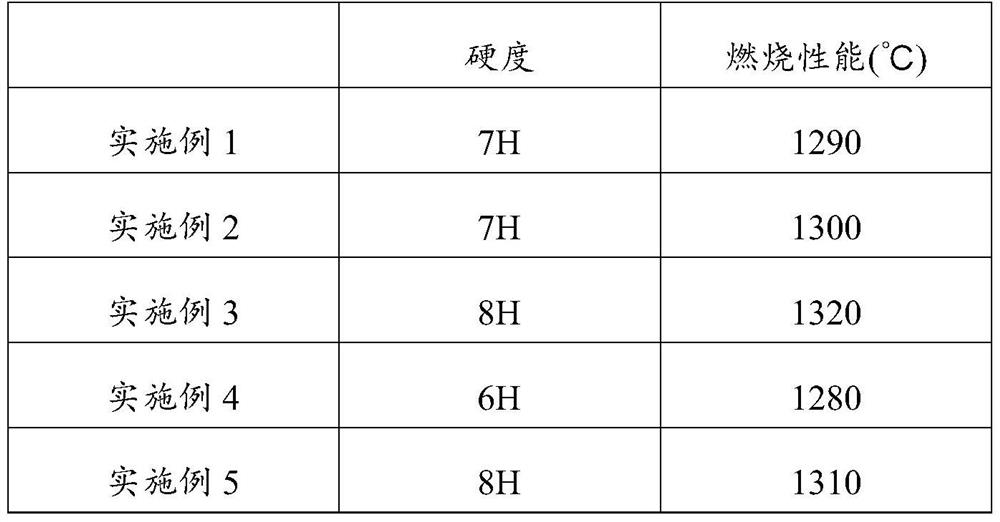

The invention discloses a water-based high-temperature-resistant anti-corrosion composition which comprises the following components in parts by weight: 45-90 parts of a polymer matrix, 15-70 parts of compact filling powder, 0.5-4 parts of rare earth metal, 5-40 parts of a dispersing agent, 2-25 parts of a flatting agent and 10-30 parts of an inorganic adhesive. The water-based high-temperature-resistant anti-corrosion composition is good in anti-corrosion performance, does not re-rust in a high-salt environment and particularly has more outstanding performance in corrosion environments such as salt mist and acid rain, the ultraviolet aging resistance is 3-5 times that of a traditional coating, the salt mist test can reach 2400 h or above, and the service life of the water-based high-temperature-resistant anti-corrosion composition meets the requirement of Centennial Project. The water-based high-temperature-resistant anti-corrosion composition disclosed by the invention is high-temperature-resistant and non-combustible, is an A-grade fireproof non-combustible material, has ultrahigh surface hardness which can reach 4-9H, particularly outstanding scratch resistance and good impact resistance, and can meet the requirements of various special environments.

Owner:烟台万华新材料技术有限公司

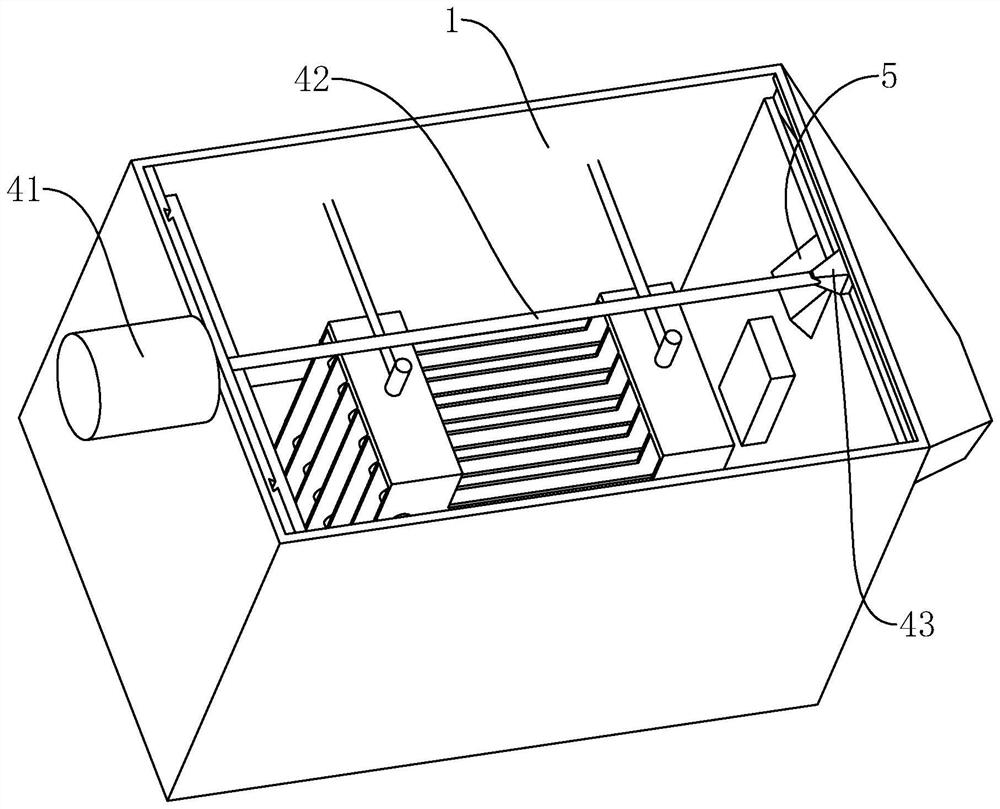

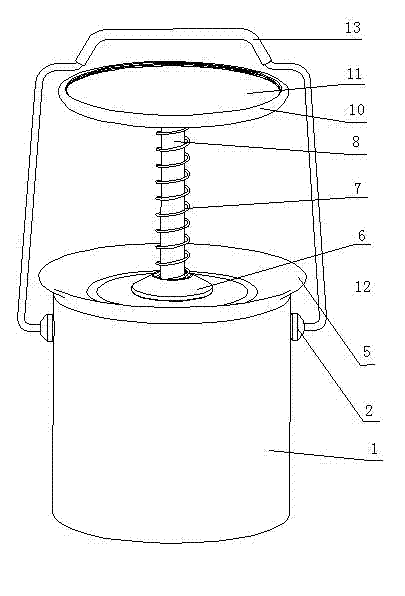

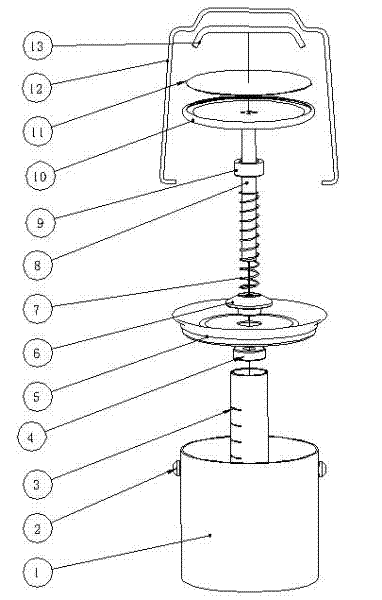

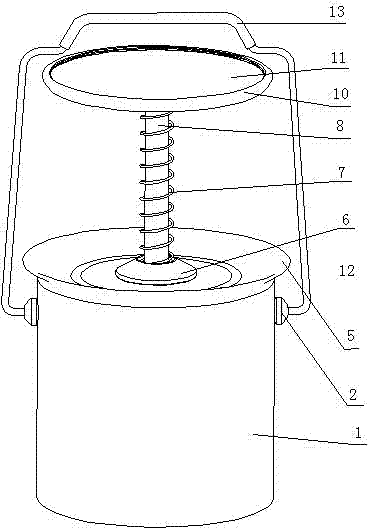

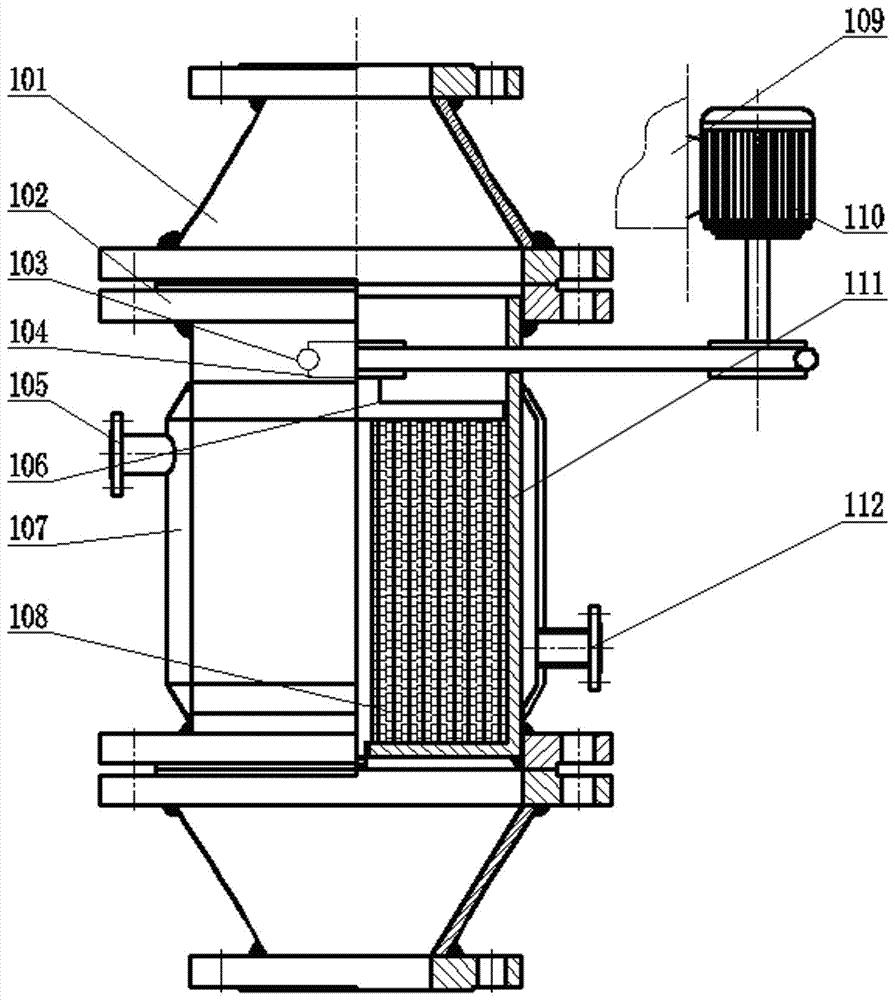

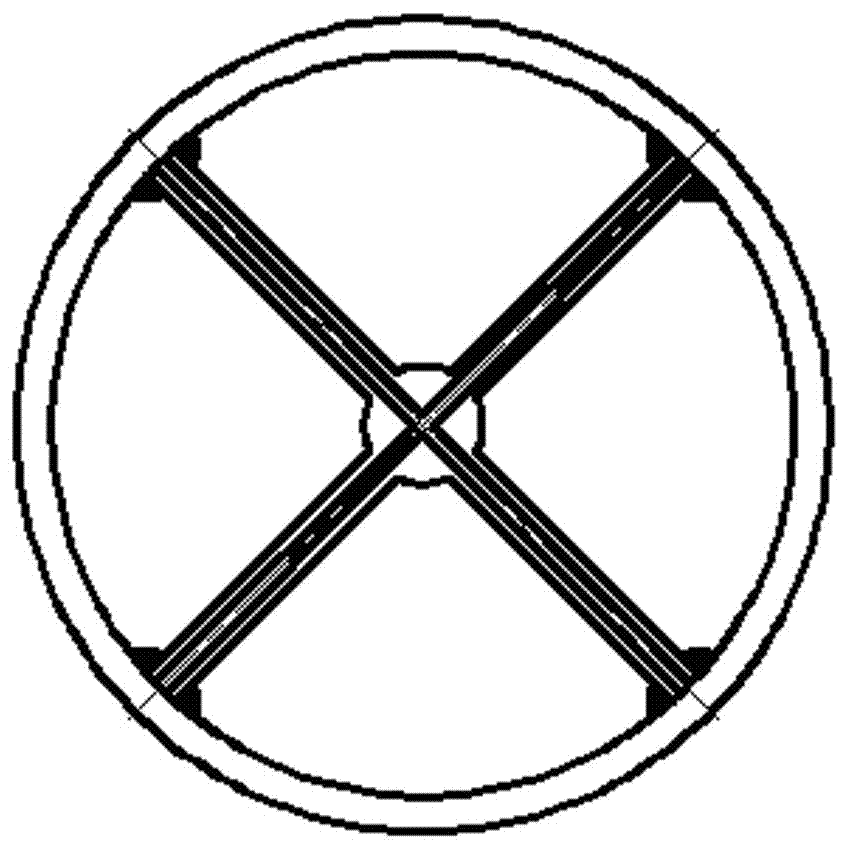

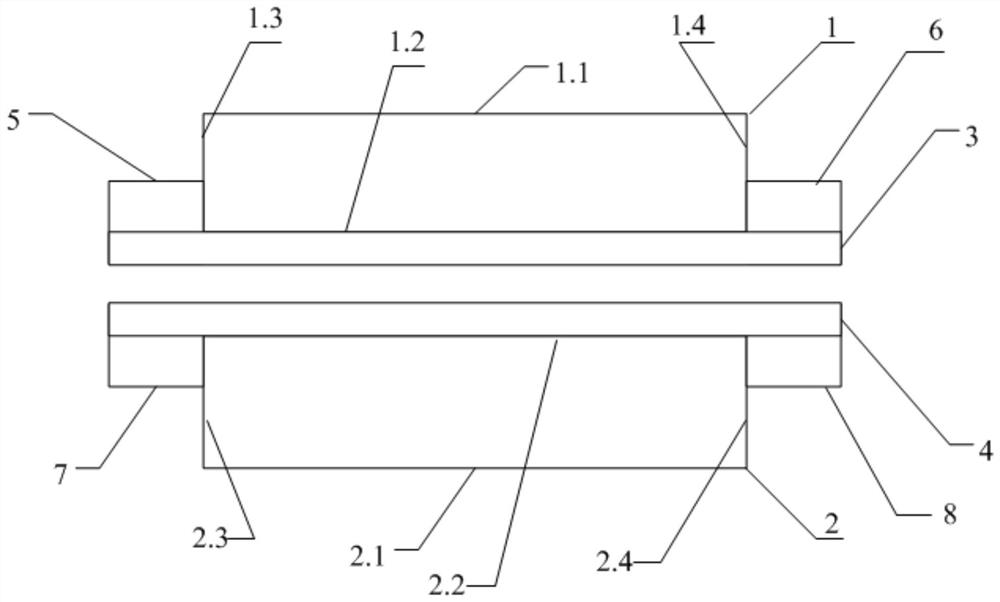

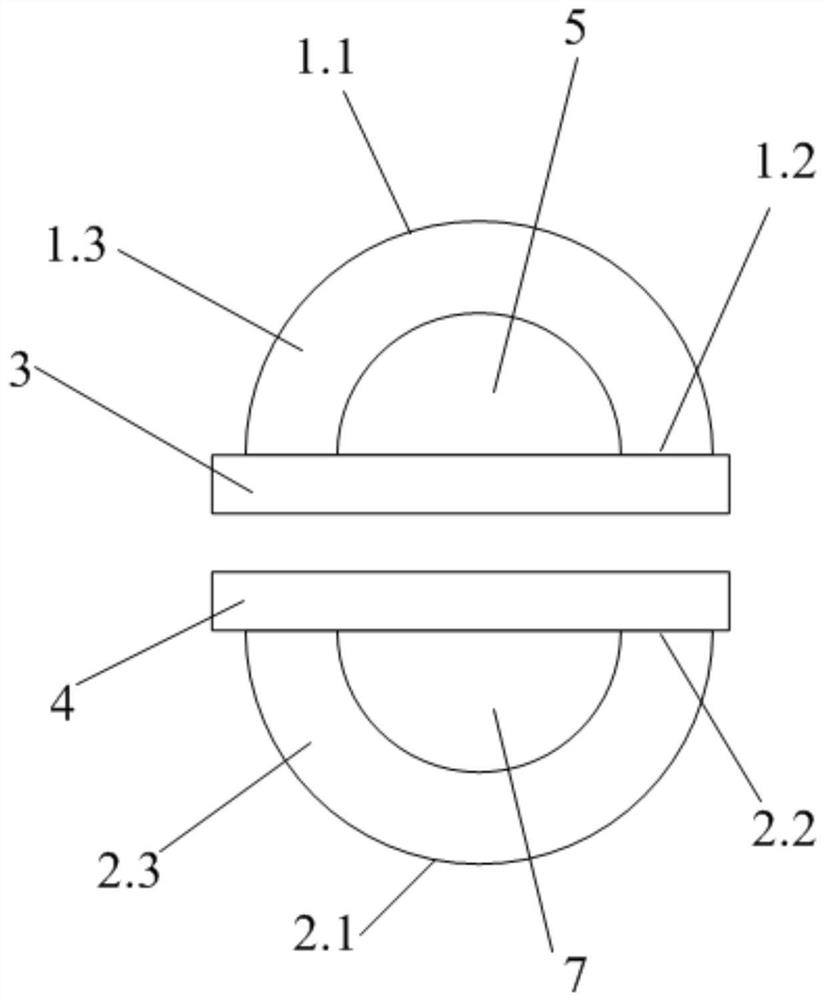

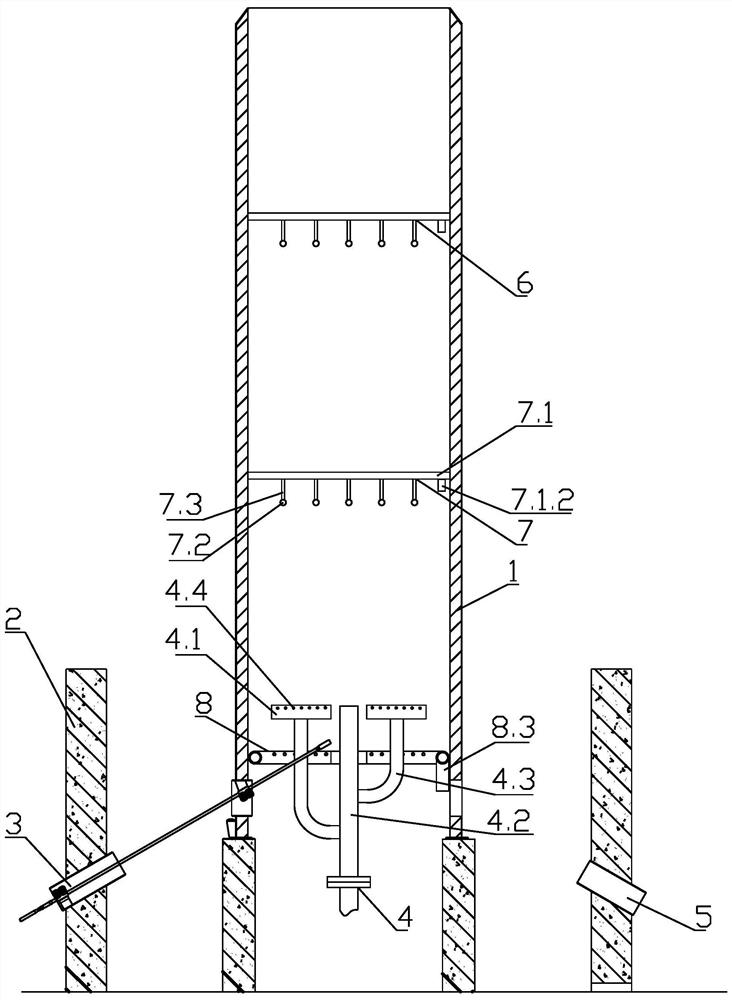

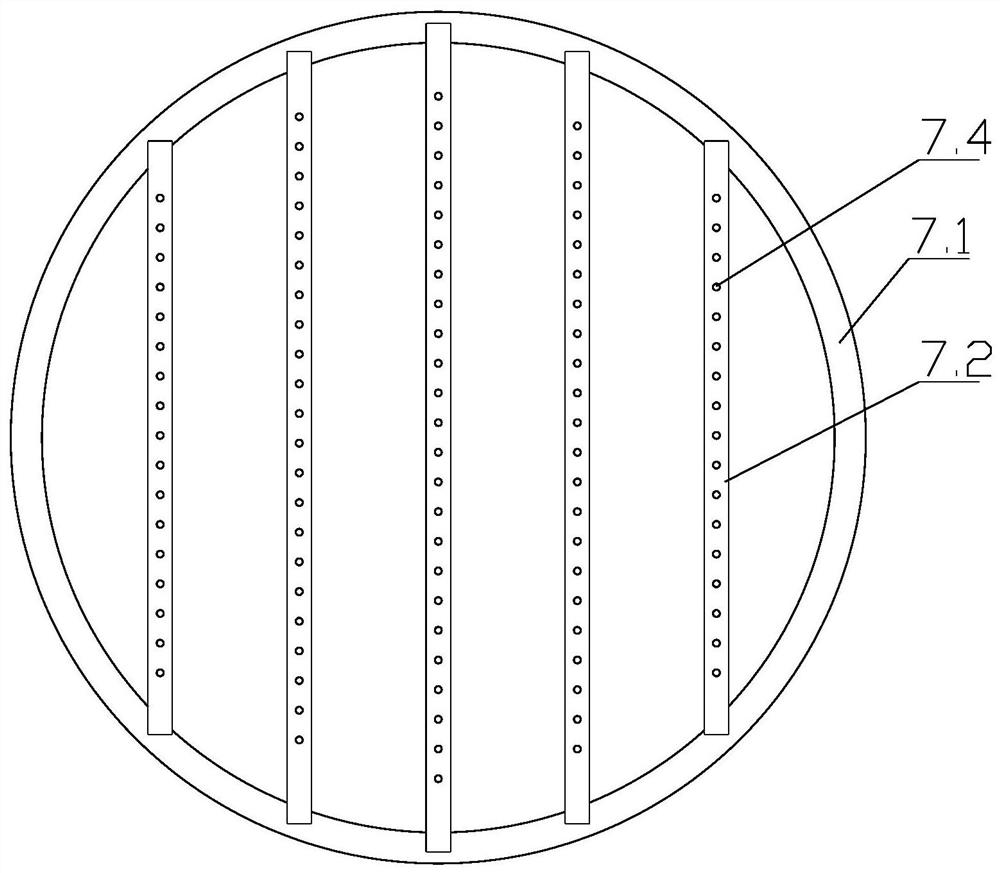

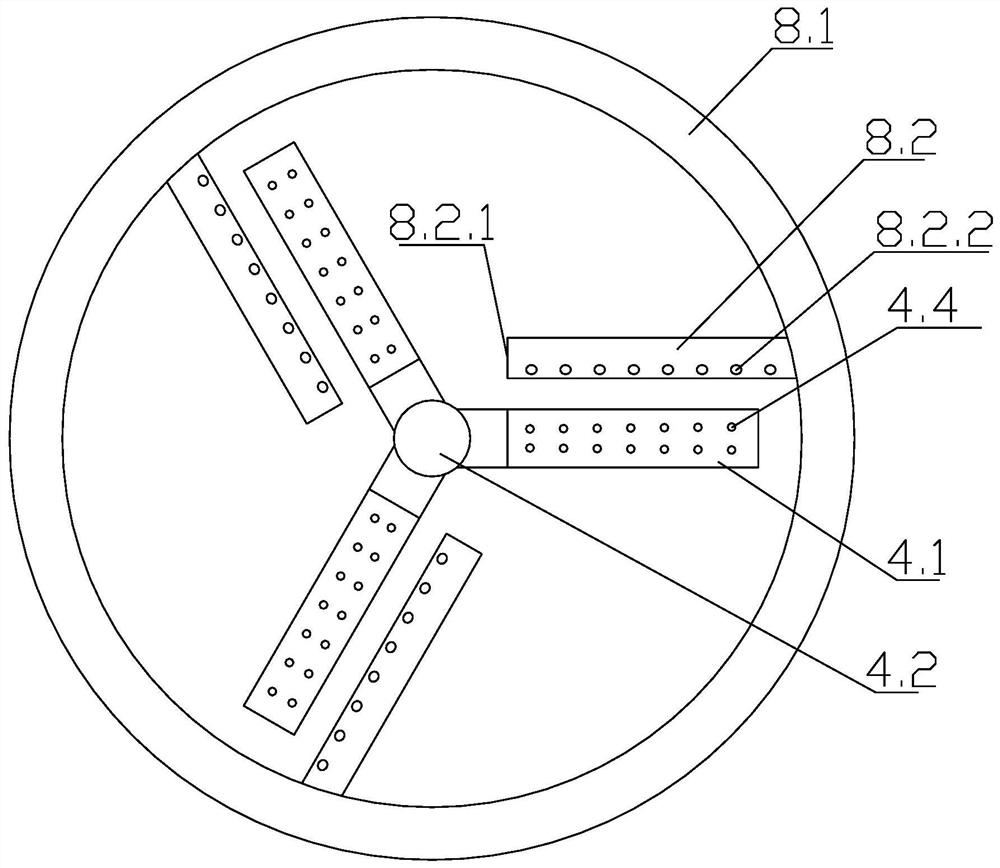

Jacketed multi-loop naphthalene forced crystallization and recycling apparatus

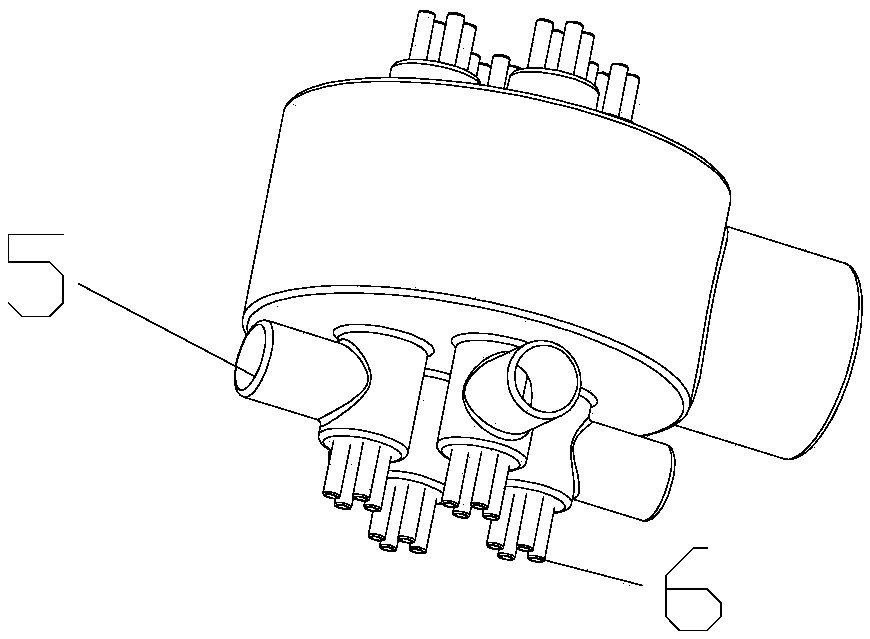

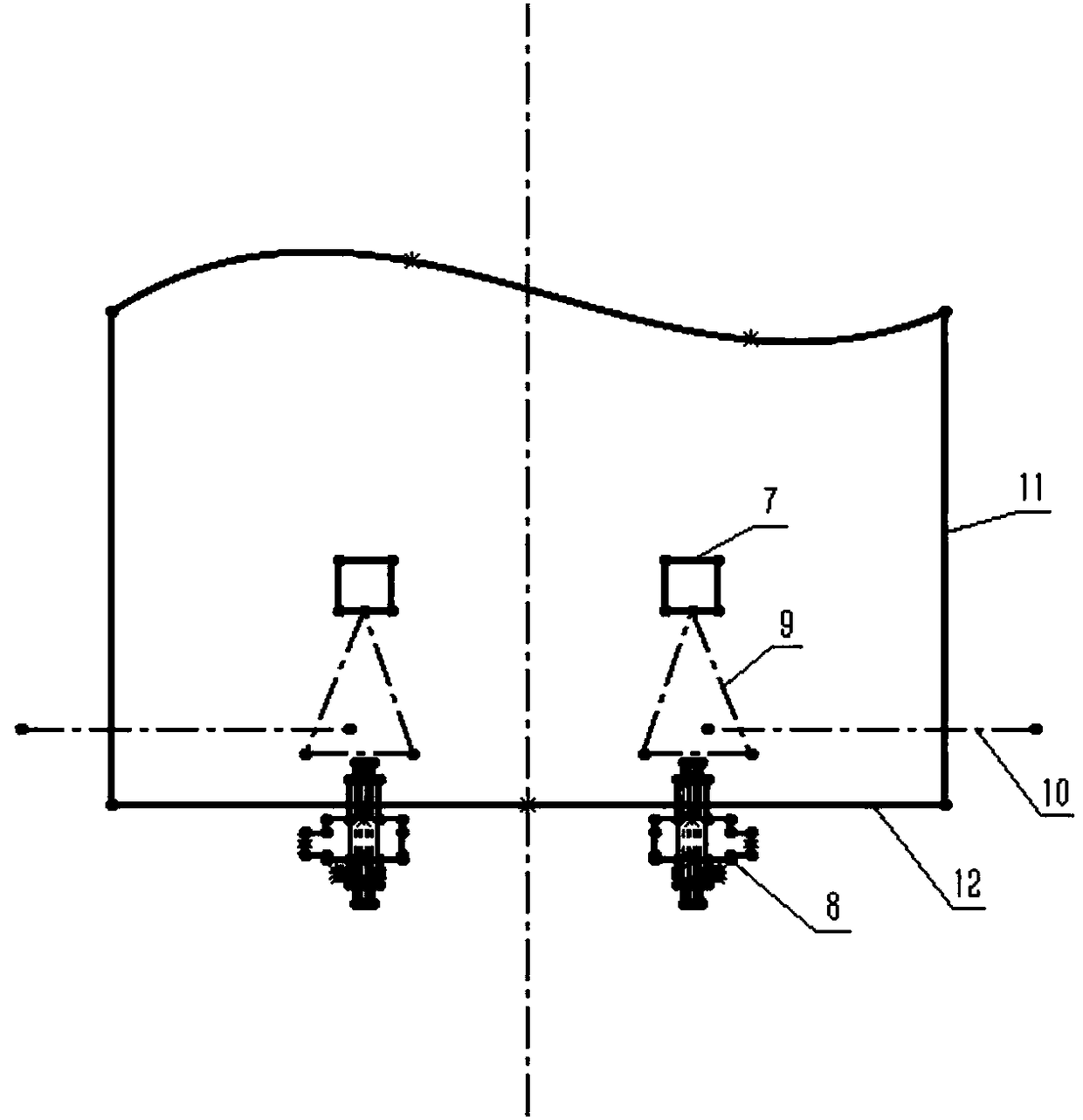

InactiveCN106215452AAvoid crystal pluggingGuaranteed to workSolution crystallizationHeat exchange cooling cystallizationBreatherMotor drive

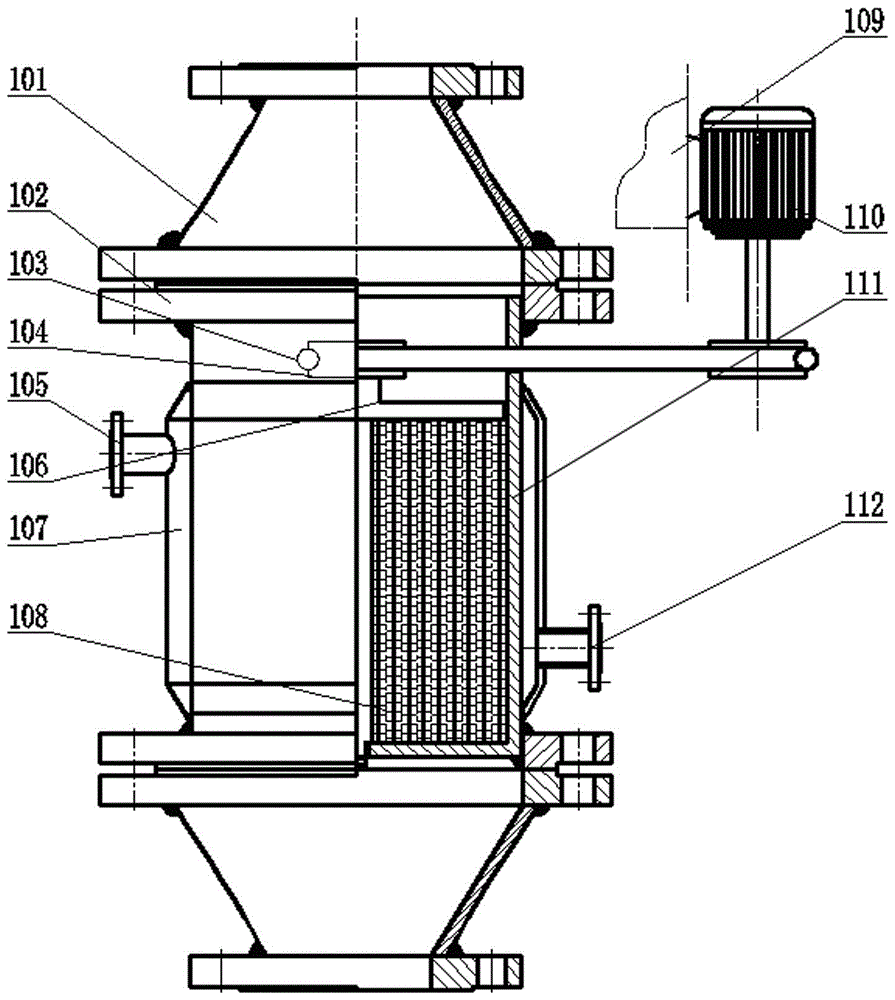

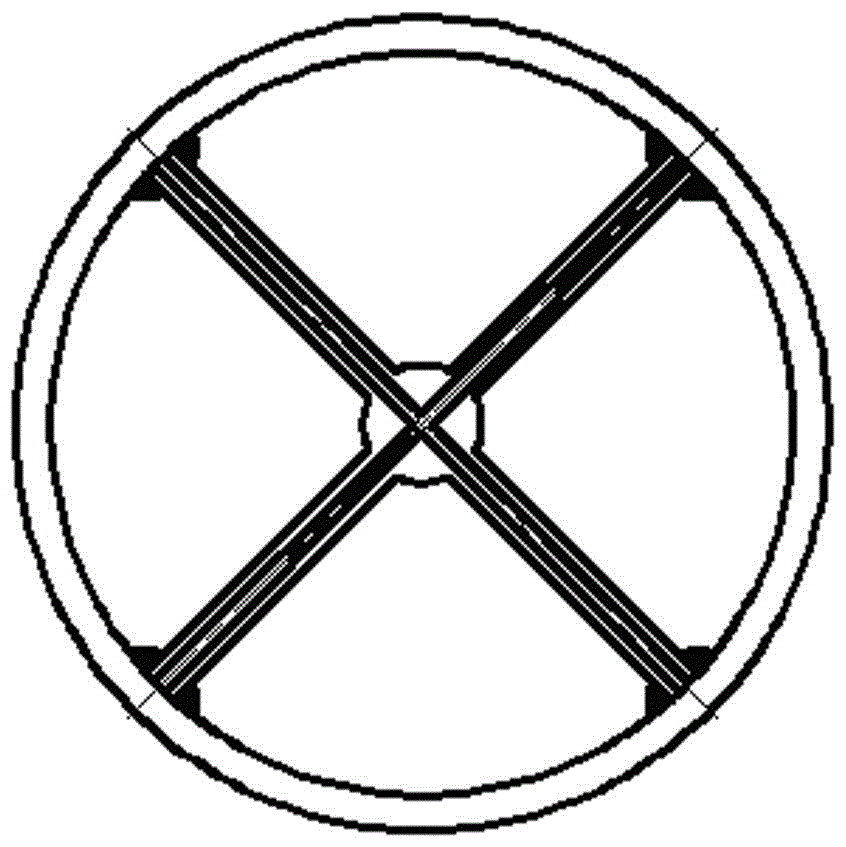

The invention relates to a jacketed multi-loop naphthalene forced crystallization and recycling apparatus, comprising a barrel, a multi-layer screen tube, a grid plate, a needle bearing, an O-shaped belt, a pulley, and a reduction motor; the needle bearing is mounted at the bottom of the barrel, a shaft lever of the grid plate is mounted in the needle bearing, the grid plate and the multi-layer screen tube are nested in a staggered manner to form a multi-loop structure; a fastening structure is provided between the bottom of the multi-layer screen tube and a bottom stand of the barrel to fix the barrel and the multi-layer screen tube; the reduction motor drives the grid plate to rotate through the o-shaped belt; the grid plate is fitted with a brush, the brush comes in frictional contact with the surface of the multi-layer screen tube when the grid plate rotates to scrape off crystal that falls into a tank. The jacketed multi-loop naphthalene forced crystallization and recycling apparatus as an auxiliary device to a naphthalene tank breather valve and is mounted between a naphthalene tank and the breather valve through a reducing flange to carry out naphthalene forced cooling and crystallization and scrape off the crystal into the tank; the jacketed multi-loop naphthalene forced crystallization and recycling apparatus is simple in structure and is easy to implement, and the problem of the prior art that naphthalene crystal blocks the top breather valve of a naphthalene storage tank is solved.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

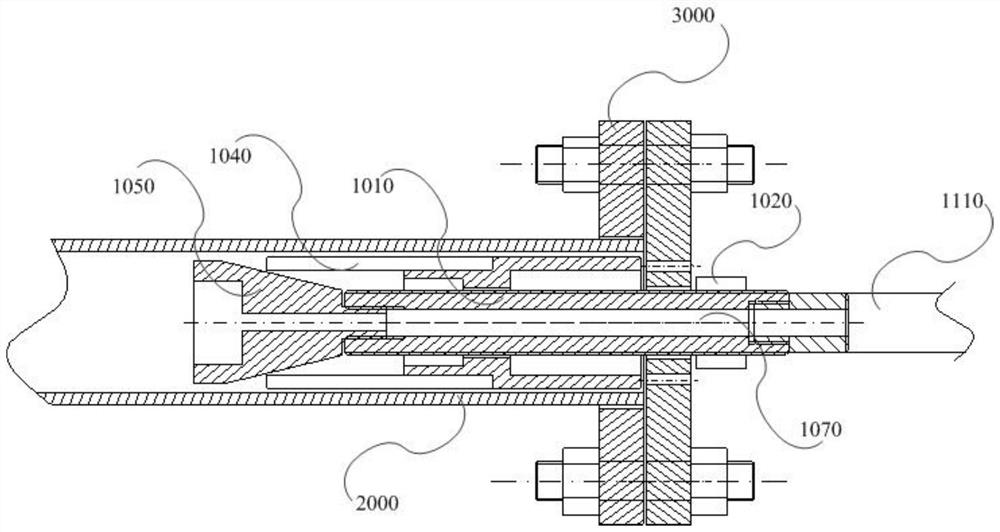

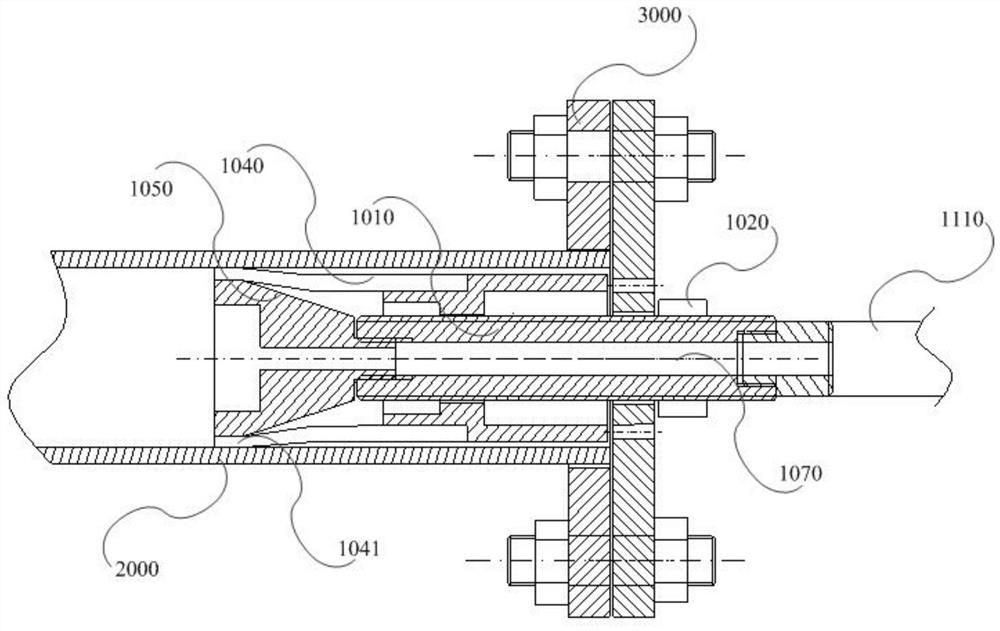

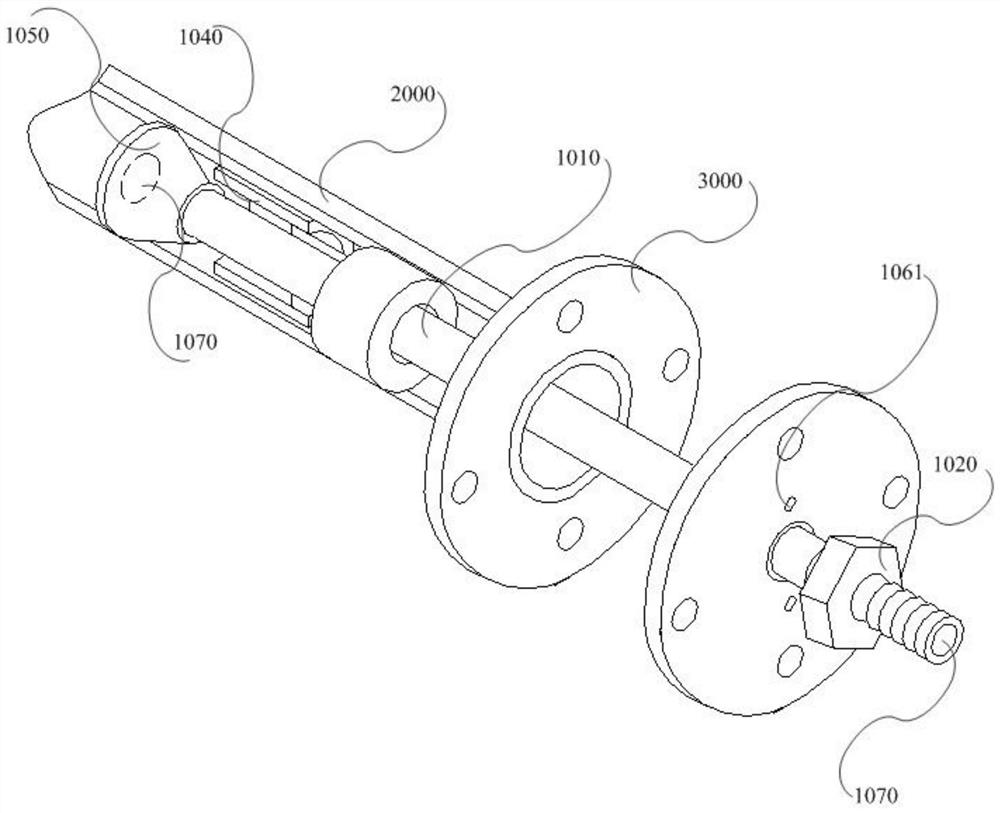

Pipeline welding and plugging device

PendingCN112344126AImprove the efficiency of welding operationsImprove efficiencyFlanged jointsPipe elementsSlag (welding)Mechanical engineering

The invention provides a pipeline welding and plugging device, and relates to the technical field of pipeline welding. The pipeline welding and plugging device provided by the invention is used for plugging a pipeline when a preset flange and the pipeline are welded. The pipeline welding and plugging device comprises a pull rod, wherein an expansion head is connected to the first end of the pull rod, and an air guide hose is connected to the second end; and a screwing nut sleeves the second end of the pull rod, and the pull rod and the expansion head fixed to the pull rod axially move relativeto the pipeline by rotating the screwing nut so as to seal the pipeline. By using the pipeline welding and plugging device, the safety of welding operation is facilitated. Impurities such as high-temperature welding slags can be prevented from entering the to-be-connected pipeline, and the service life of the pipeline can be prolonged.

Owner:PETROCHINA CO LTD

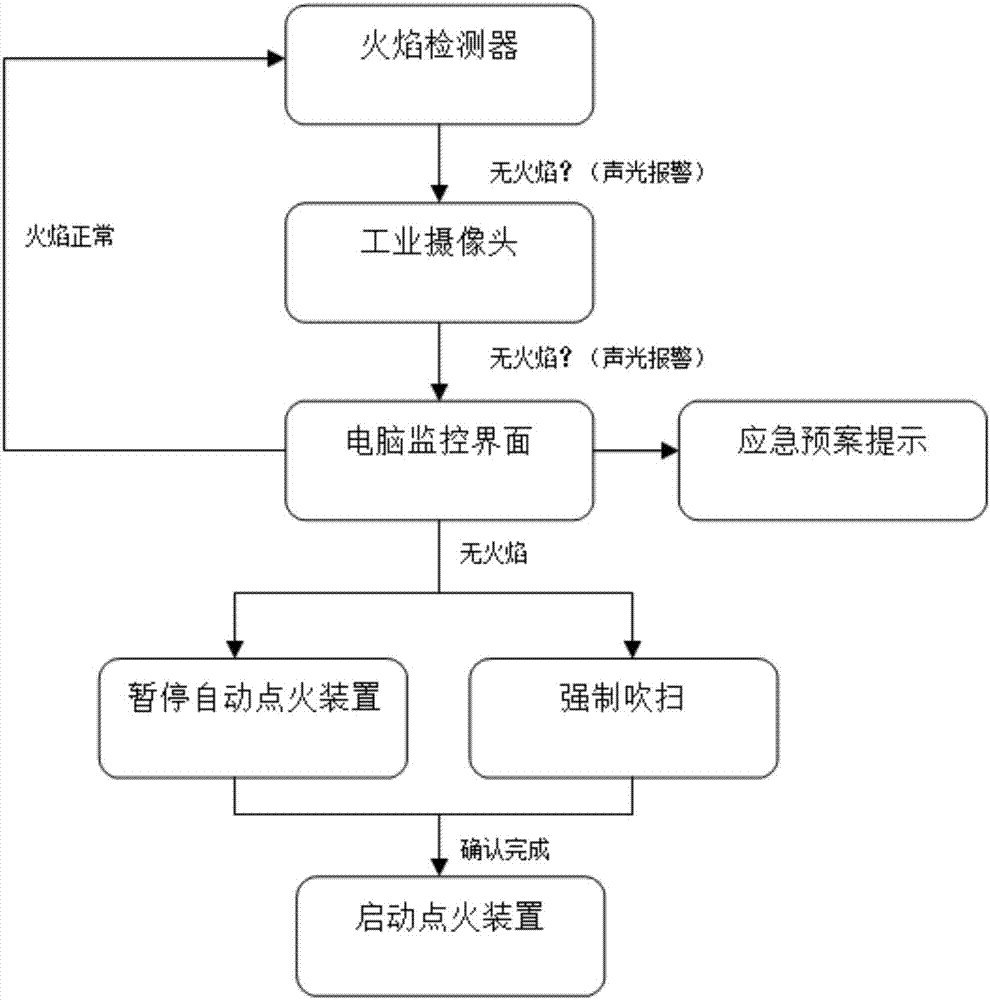

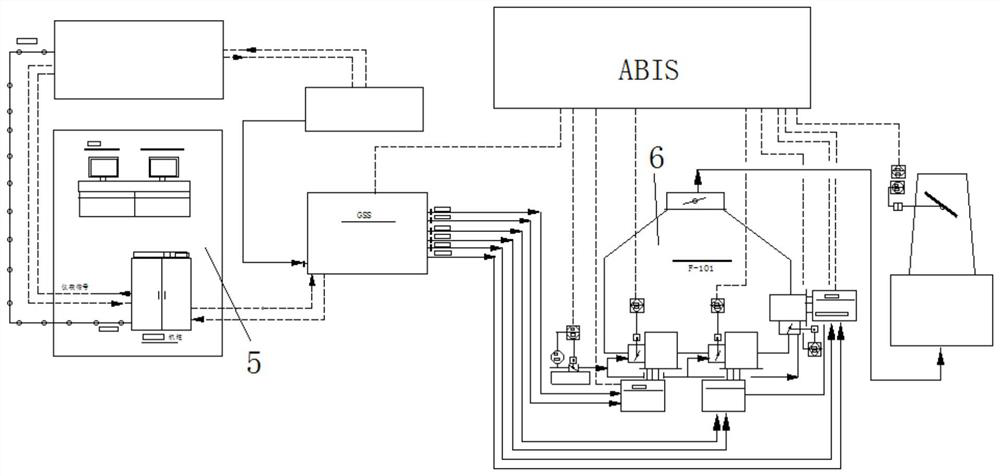

Flame monitoring technology optimization method for improving safety of combustion furnace

InactiveCN107013935ARealize real-time monitoringImplement emergency plan tipsChamber safety arrangementComputer monitorEmergency plan

The invention relates to a flame monitoring technology optimization method for improving the safety of a combustion furnace, which mainly solves the problem that dangerous accidents cannot be effectively avoided in the prior art. The present invention comprises the following steps by adopting a kind of flame monitoring technology optimization method that improves combustion furnace safety: step one, setting flame monitoring equipment, main equipment comprises flame detector and industrial camera; Step 2, setting the alarm of flame detector ( sound and light alarm), and the linkage real-time monitoring (sound and light alarm) of the industrial camera and the flame detector, set the computer monitoring interface to prompt the emergency plan; step 3, set the automatic ignition program to stop using, set the forced purging process steps, wait for the whole The technical scheme of restarting the ignition program after all steps are completed solves the above problems well, and can be used in the safety control of GE coal-water slurry gasifier.

Owner:CHINA PETROLEUM & CHEM CORP +1

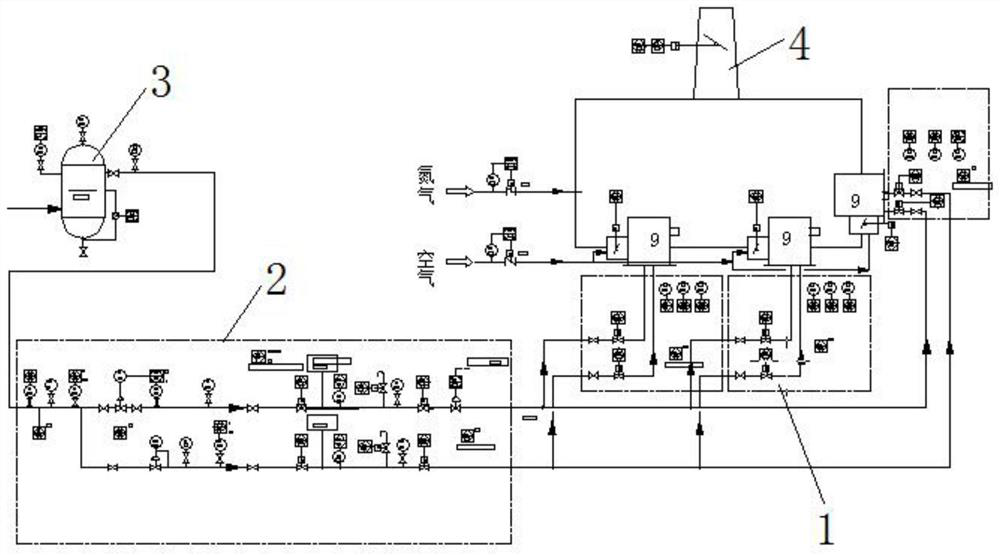

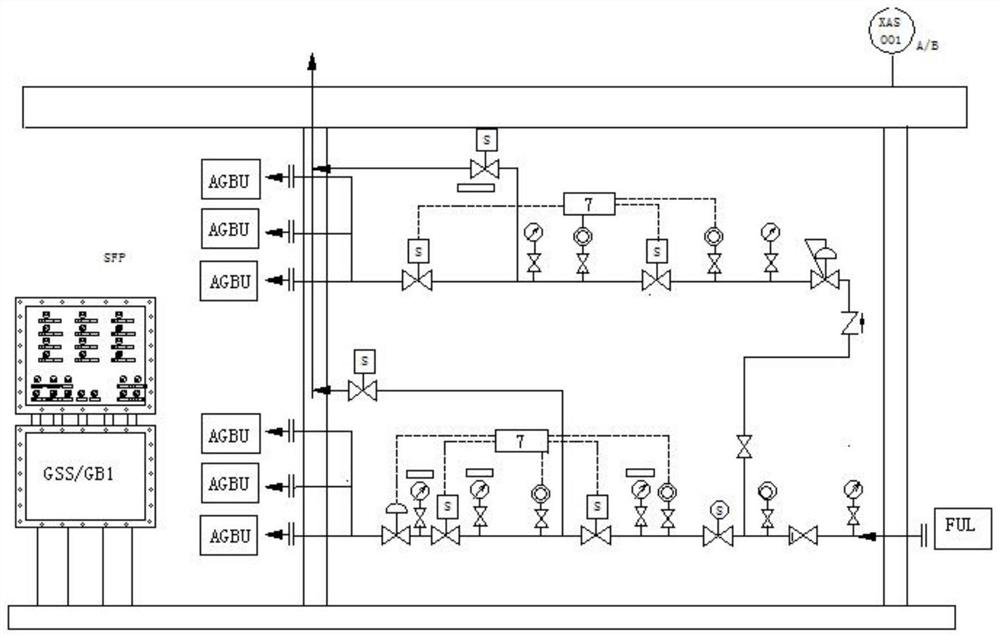

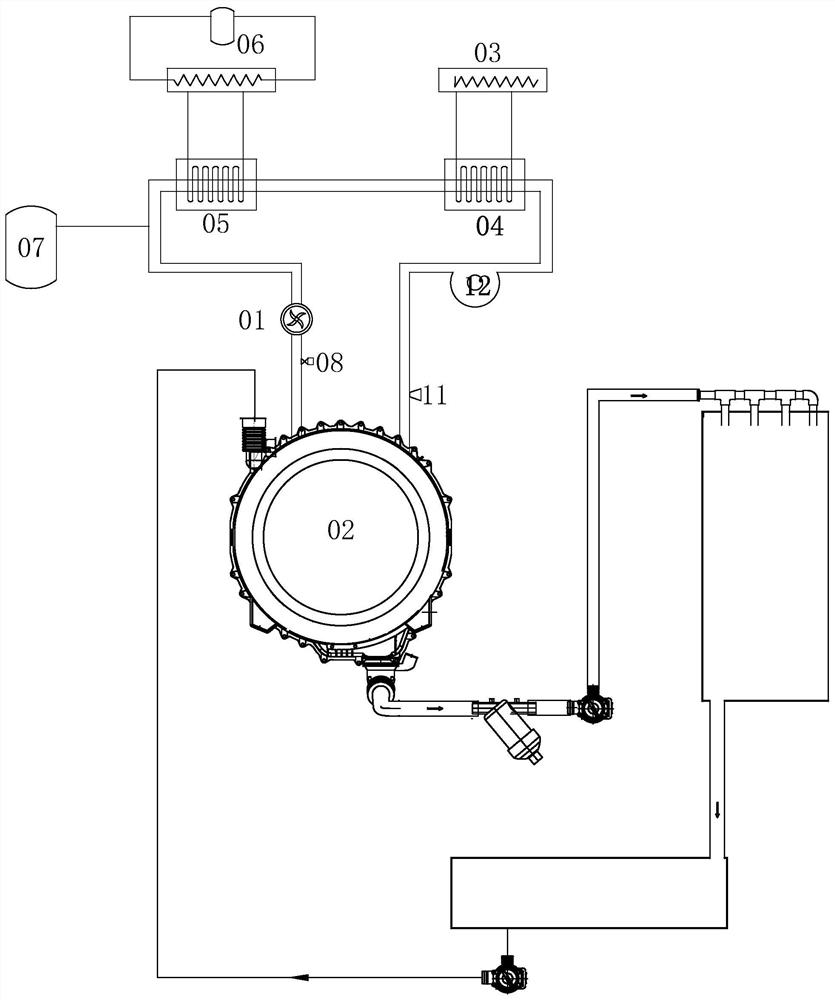

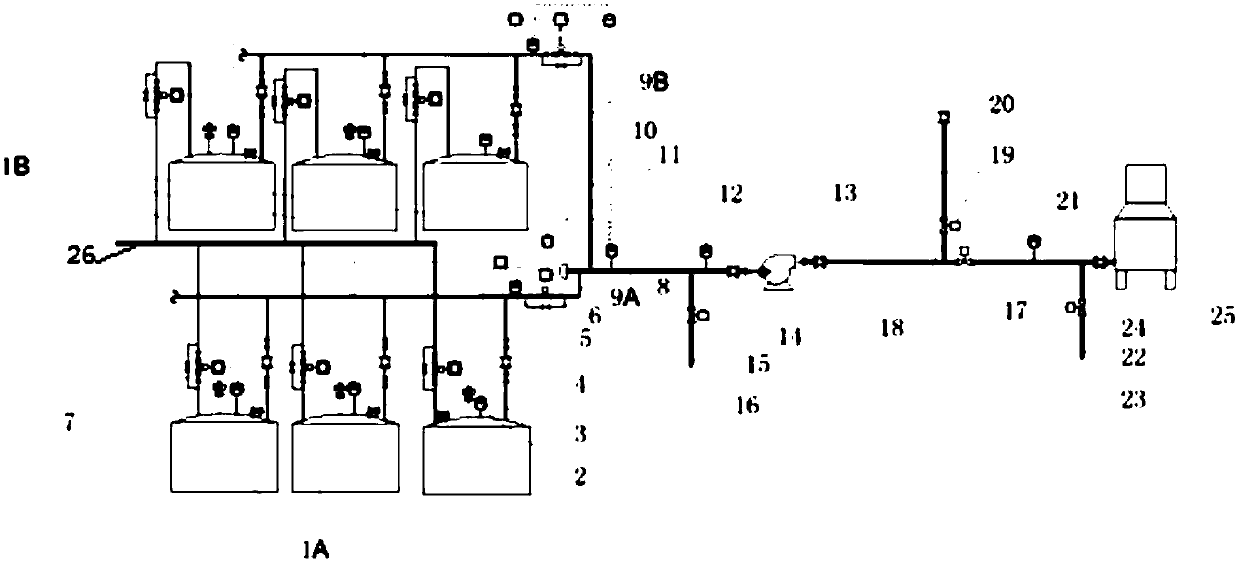

Ignition system of intelligent gas burner

InactiveCN112413640AEnsure ignition reliabilityAvoid flash explosionFire rescueCombustion ignitionNitrogen gasMechanical engineering

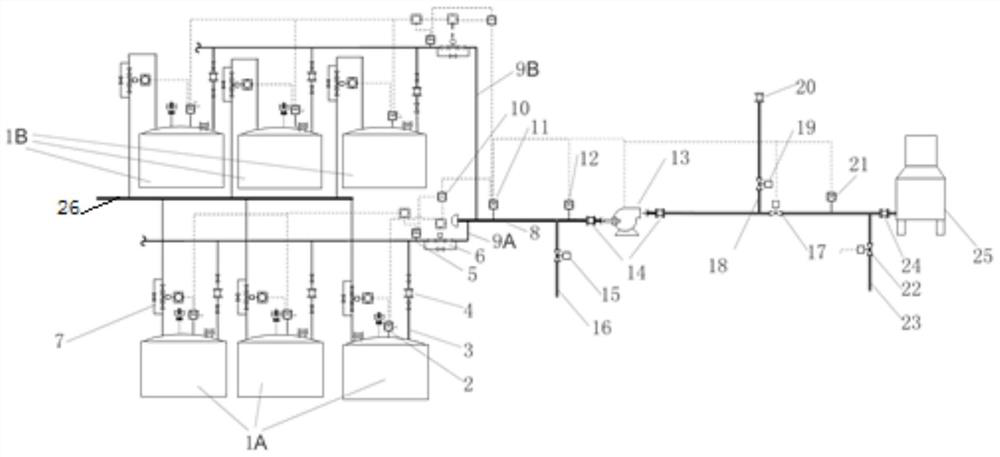

The invention discloses an ignition system of an intelligent gas burner, and relates to the technical field of burner ignition devices. The ignition system comprises a combustor ignition part which isskid-mounted in closed equipment and a gas conveying part which is skid-mounted in another closed equipment, wherein the combustor ignition part is provided with an intelligent ignition state tracking subsystem, an ever-burning lamp ignition subsystem, a combustor ignition subsystem, a nitrogen purging subsystem, a double-valve leakage detection subsystem and a fire extinguishing subsystem; the gas conveying part is provided with the double-valve leakage detection subsystem; and the gas conveying part is used for conveying gas to the combustor ignition part. The ignition efficiency is high, and the safety of the ignition process is high.

Owner:上海轻叶能源股份有限公司

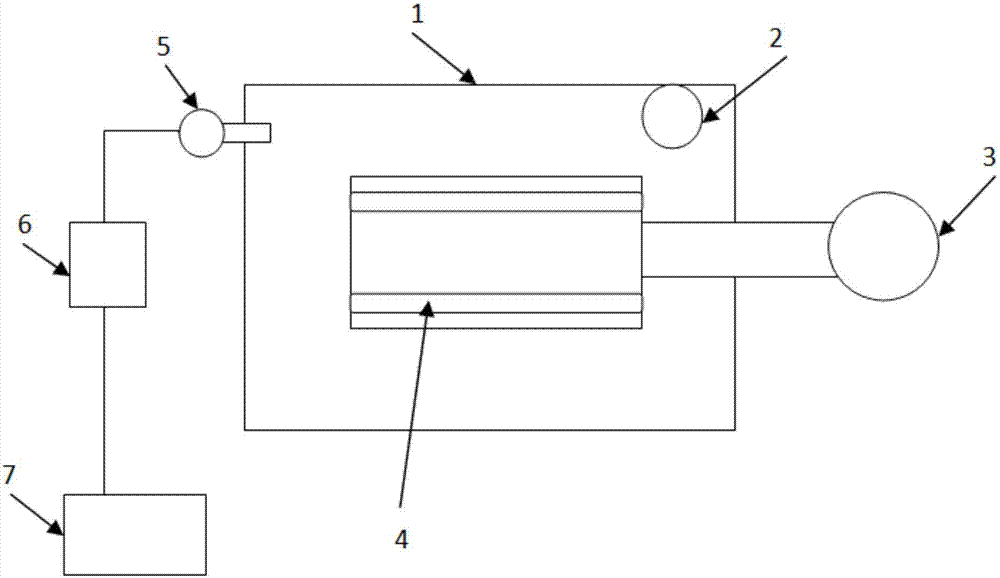

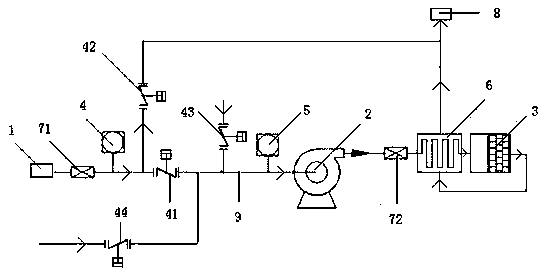

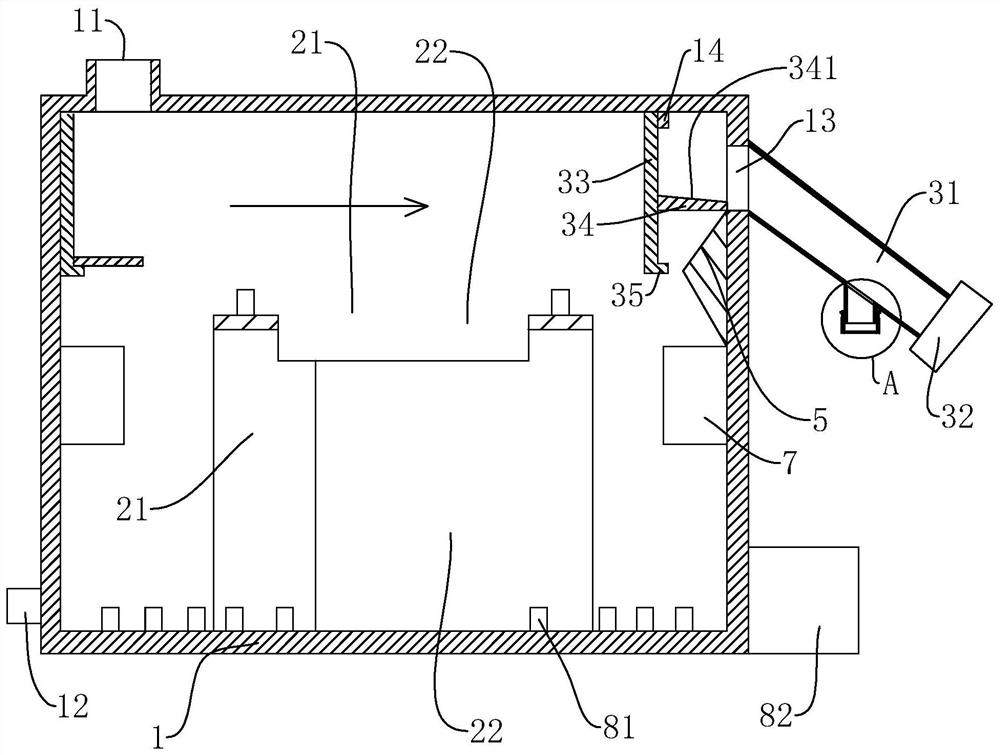

Explosion-proof catalytic oxidation device

PendingCN109200818AAvoid overheatingAvoid flash explosionDispersed particle separationCatalytic oxidationInlet valve

The invention provides an explosion-proof catalytic oxidation device, the explosion-proof catalytic oxidation device comprises an exhaust gas supply device for providing exhaust gas; an induced draftfan for guiding exhaust gas transportation; a catalytic oxidation device connected with an air supply port through a main pipe; a first oxygen content analyzer which is disposed between the exhaust gas supply device and the induced draft fan, and used for monitoring the oxygen content of the exhaust gas supplied by the exhaust gas supply device; and a gas intake valve which is disposed between thefirst oxygen content analyzer and the induced draft fan; a first branch pipe is also disposed between the first oxygen content analyzer and the gas intake valve, and an emergency vent valve is disposed on the first branch pipe; and a second branch pipe is further disposed between the gas intake valve and the induced draft fan, and is used for introducing air, and a second branch valve is arrangedon the second branch pipe. The explosion-proof catalytic oxidation device can effectively avoid the over-temperature operation of a catalytic oxidation unit, and can effectively prevent the flash explosion of a high hydrocarbon-containing gas.

Owner:JIANGSU XINJIUYANG ENVIRONMENTAL PROTECTION EQUIP TECH

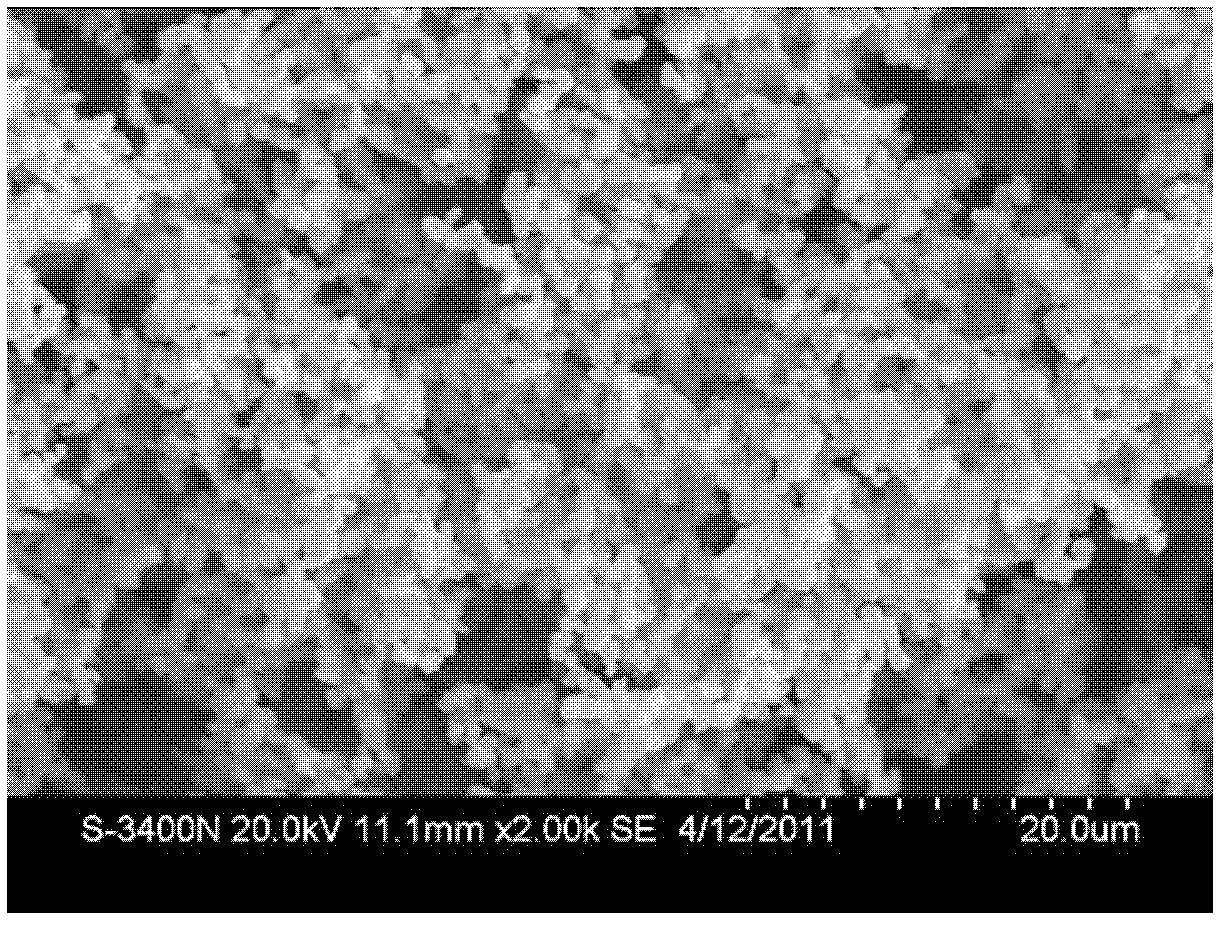

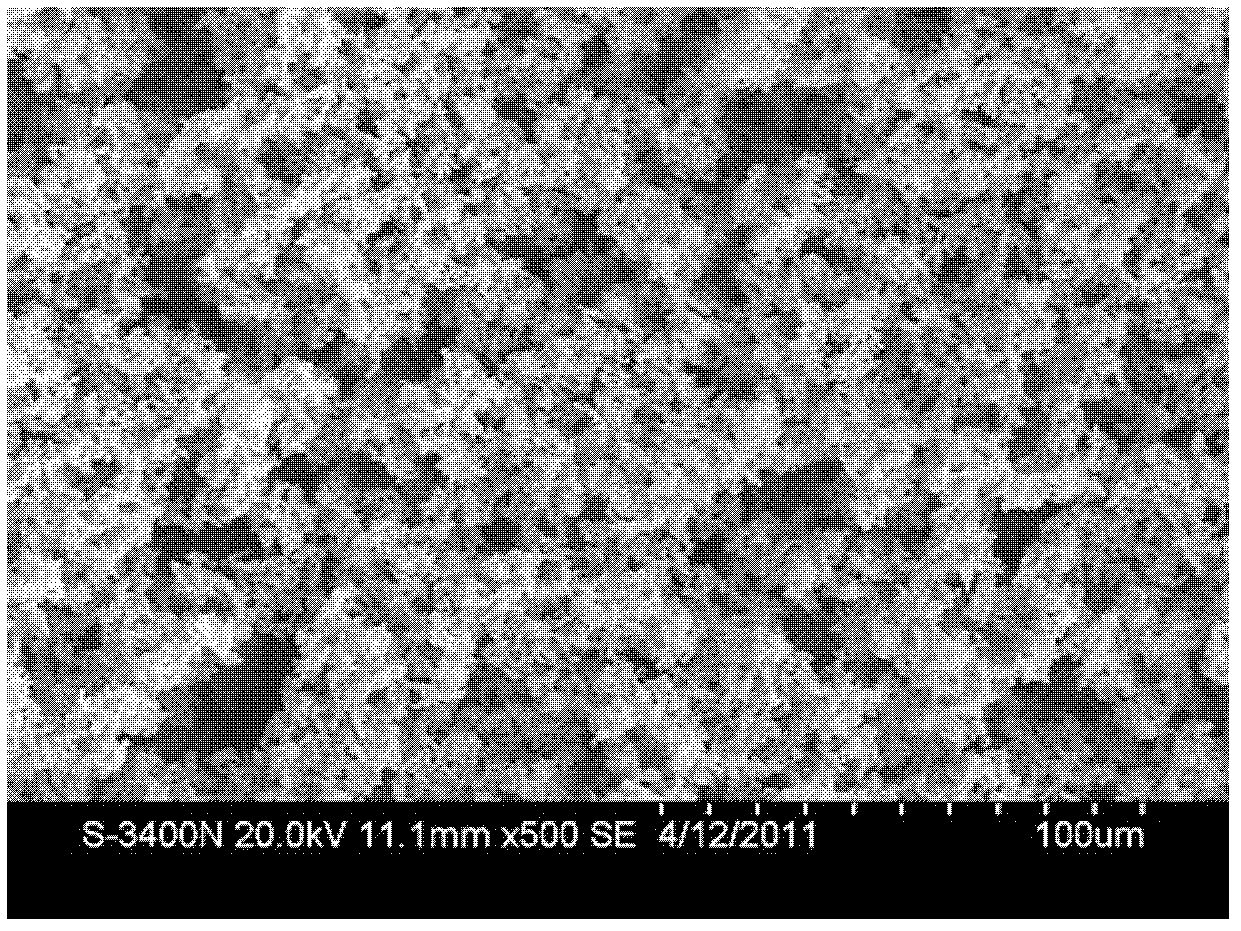

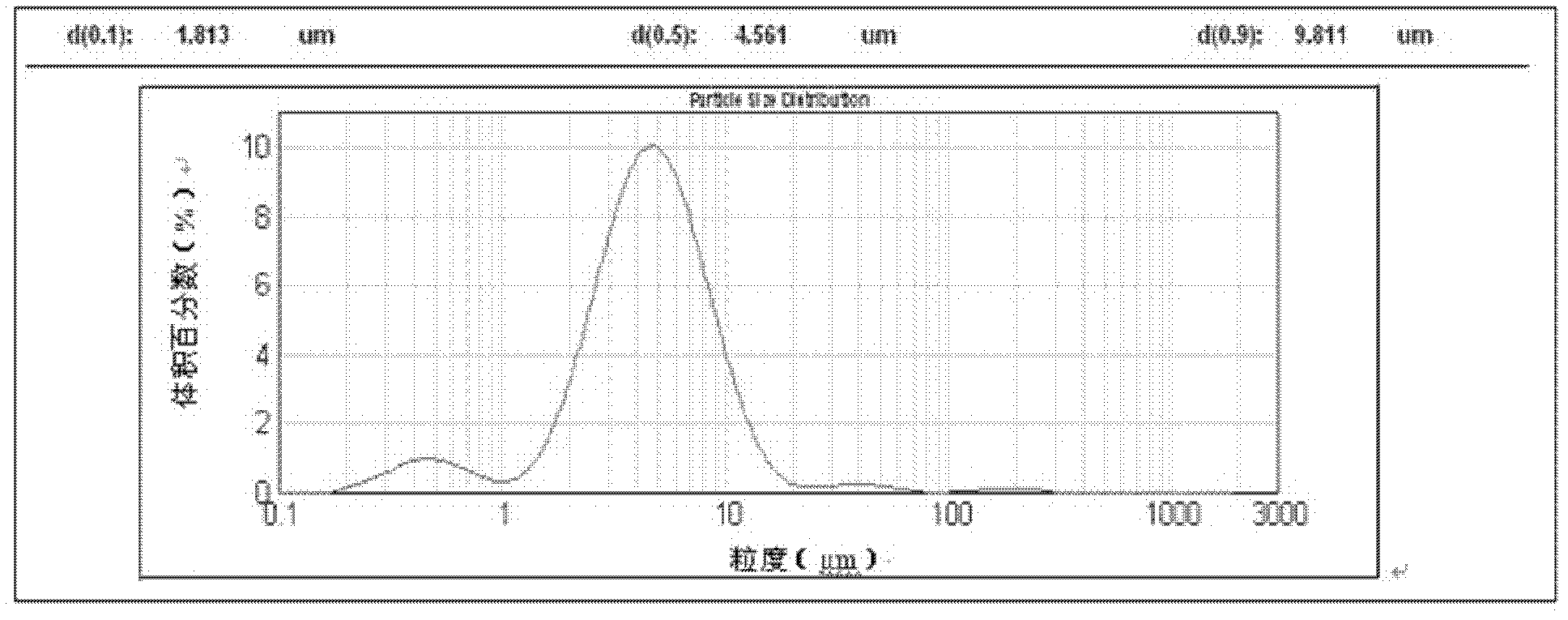

A kind of preparation method of small particle size doped potassium-molybdenum alloy powder

The invention discloses a preparation method of small-granularity potassium-doped molybdenum alloy powder. The method comprises the following steps of: sieving potassium-doped molybdenum dioxide serving as a raw material; placing the sieved raw material into a reduction furnace in a single temperature region; performing reduction treatment for 3.5 to 5.5 hours under the conditions of hydrogen flow of 10 m<3> / h to 14 m<3> / h and constant temperature of between 940 and 970 DEG C; and cooling along with the furnace to obtain the potassium-doped molybdenum alloy powder with the average granularityof 1.5 to 3.5 mu m. The method is simple; the reduction temperature is low; the reduction time is short; the granularity of the reduced molybdenum alloy powder is controlled not to enlarge and the volatile loss of the potassium element is controlled; the wastage rate of the potassium element is not more than 25 percent; the advantages of high efficiency and energy conservation are achieved; and the prepared potassium-doped molybdenum alloy powder can be sintered by the conventional sintering process and the subsequent treatment process is simple.

Owner:JINDUICHENG MOLYBDENUM CO LTD

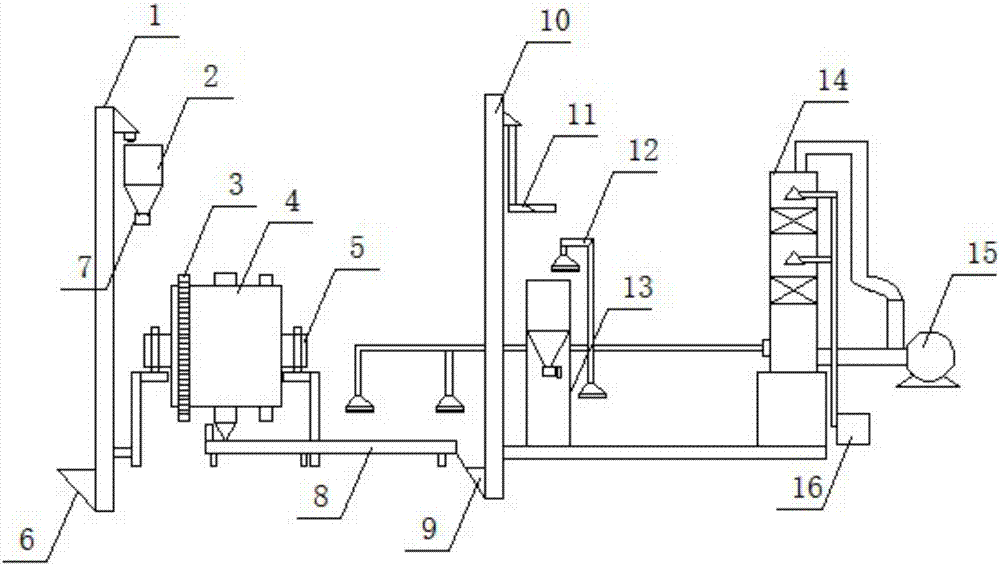

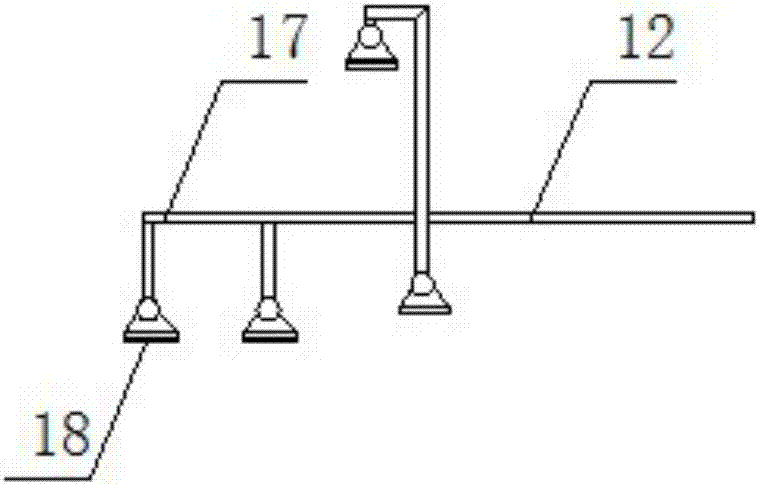

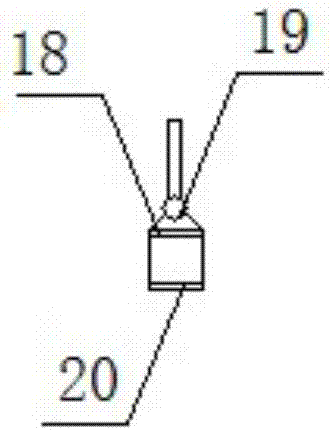

Chlorosilane-containing silane tail gas treatment method

ActiveCN108261883AIncrease throughputReduce lossesGas treatmentDispersed particle separationCombustion systemSilanes

The invention discloses a chlorosilane-containing silane tail gas treatment method, comprising the steps of (1) subjecting chlorosilane to primary condensation; (2) subjecting chlorosilane to secondary condensation; (3) performing separating to obtain chlorosilane; (4) stabilizing pressure with a gas pressure stabilizer tank; (5) combusting silane gas. The chlorosilane-containing silane tail gas treatment method has the advantages that chlorosilane in silane tail gas is recycled, the recycled chlorosilane is reusable for silane production systems, material loss is reduced, and production costis reduced; a combustion system herein has multiple combustion heads, the combustion system has positive pressure, the combustion heads are exposed in air, an anti-irradiation heat-insulating hood isarranged above, and air around a combustor is gathered around the combustor via the chimney effect; compared with traditional combustors, the combustion system allows silane tail gas and air to be mixed more sufficiently, so that combustion efficiency is significantly improved and silane tail gas treatment quantity is increased.

Owner:ORISI SILICON

Explosion-proof rapid grinding production technology

The invention discloses an explosion-proof rapid grinding production technology, which includes the production and processing of inflammable and explosive products such as sulfur powder. The beneficial effects of the present invention are: the import of raw materials adopts strong magnetism to remove iron to avoid spark explosion caused by the impact of the system after the iron enters; all the equipment in contact with the inflow of raw materials and the outflow of finished products are made of non-metallic materials or non-metallic linings, Avoid the explosion of friction sparks with metals; for the grinding process of raw materials, use non-metallic lining grinding equipment with a lower grinding speed and water cooling during the grinding process to avoid high-temperature explosions, and use the system to vacuumize and fill nitrogen for grinding Protection, and a pressure relief device is used to avoid operating accidents caused by excessive pressure. A dust recovery device is installed in the process device to ensure that the operating environment meets occupational hygiene requirements. In addition, the dust recovery device adopts negative pressure suction, and the conveying pipe adopts atomization humidification and water washing for dust removal to avoid dust explosion.

Owner:GUANGXI UNIV +1

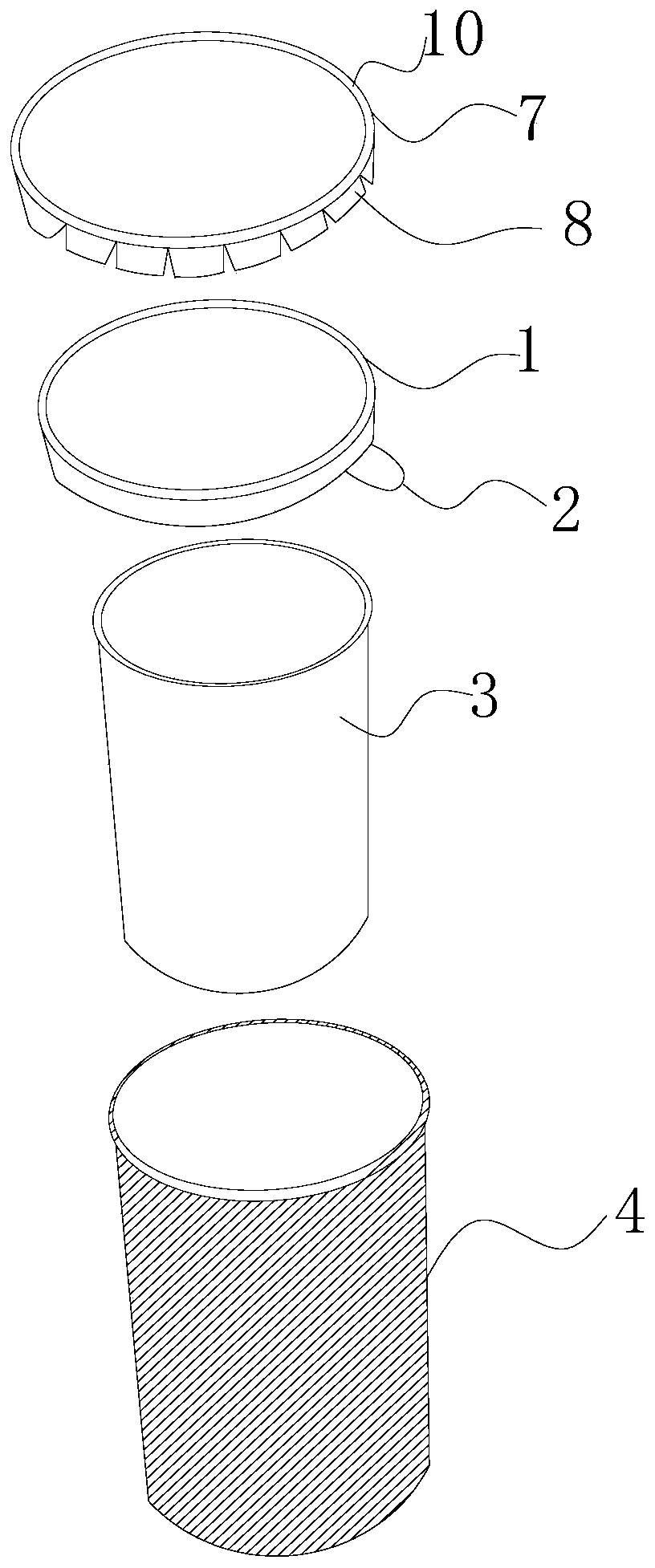

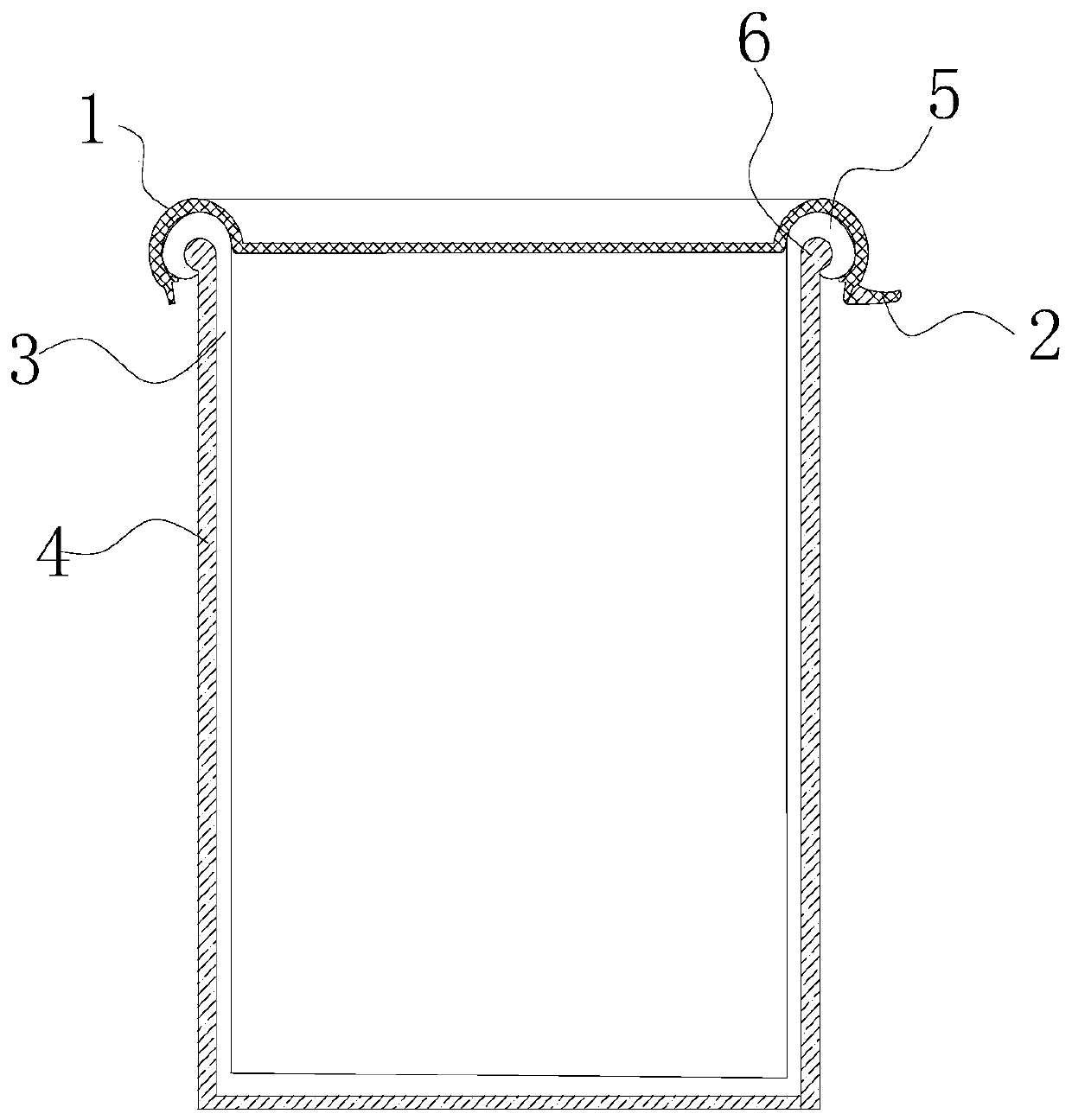

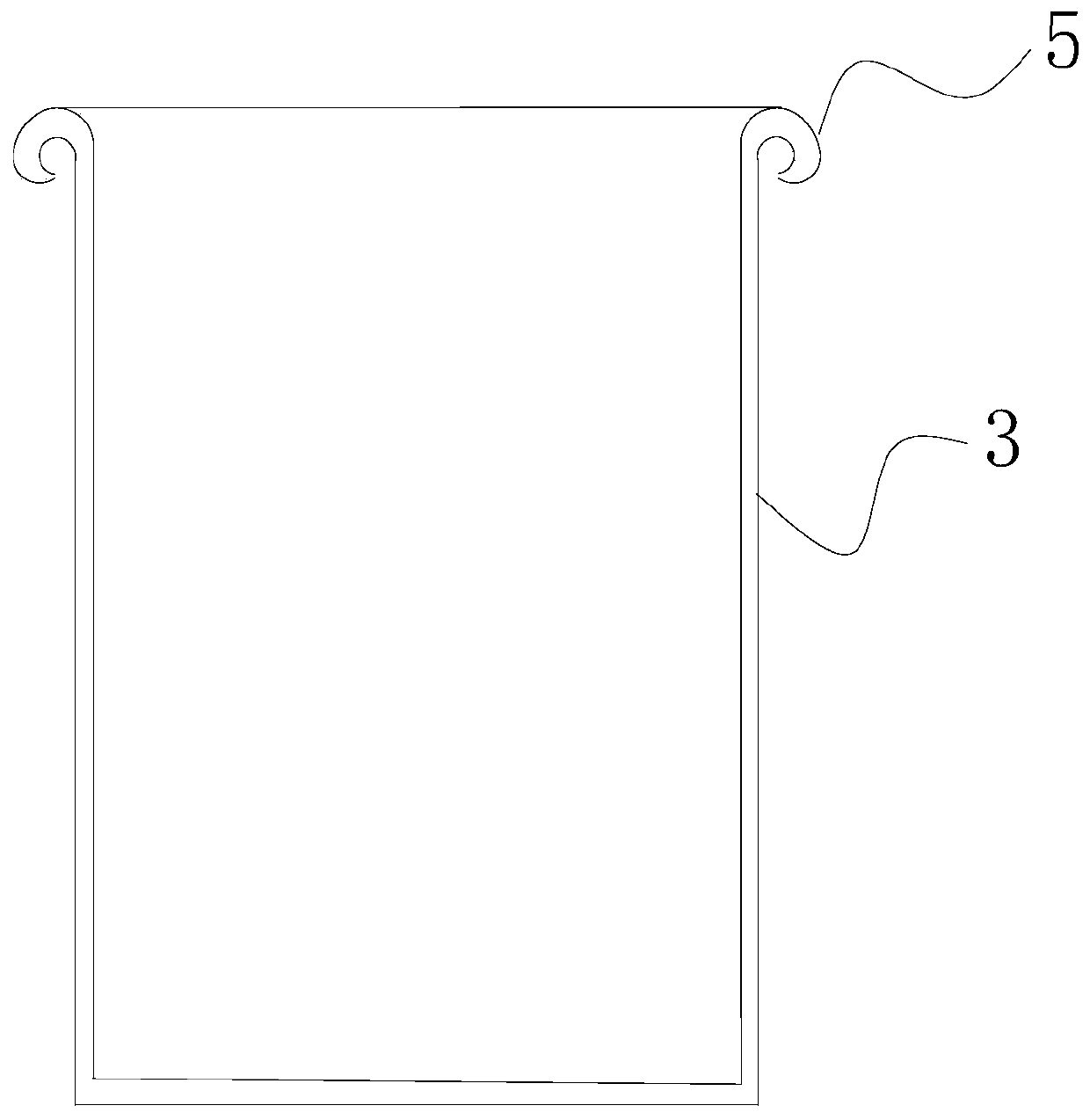

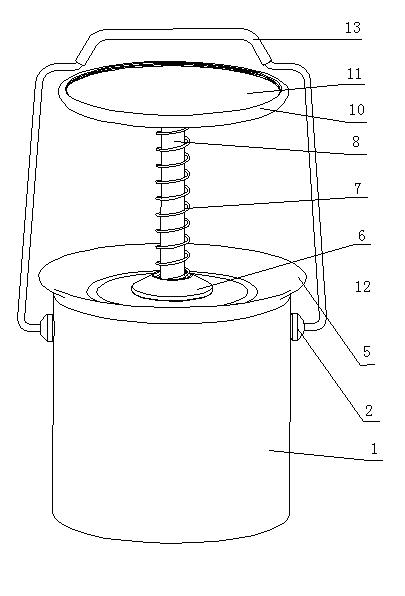

Oil paint packaging container inner sleeve

InactiveCN110525782APrevent proliferationSolve processing problemsClosures with opening deviceClosure with auxillary devicesOil paintMechanical engineering

The invention discloses an oil paint packaging container inner sleeve. The inner sleeve comprises an oil paint container and an oil paint packaging container inner sleeve body, wherein the oil paint packaging container inner sleeve body is separably arranged in the oil paint container; a container buckling edge is wound around the periphery of an opening of the oil paint container, and an inner sleeve buckling edge is wound around the periphery of an opening of the oil paint packaging container inner sleeve body. The inner sleeve buckling edge is separably buckled on the container buckling edge. According to the invention, the problems that oil paint is adhered to the container so that that it is difficult to clean the container and the oil paint residuals are left over and the like can beeffectively avoided, so that the oil paint container is recycled, the disposal quantity of dangerous packing materials is greatly reduced, and the purpose of environmental protection is achieved. Then, static electricity in the barrel is effectively diffused to the packaging container through the inner sleeve and then diffused to the ground through the packaging container, and therefore flash explosion caused by the static electricity is avoided.

Owner:珠海市威旗防腐科技股份有限公司

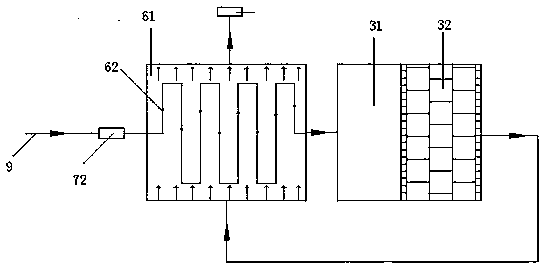

Electrocatalytic oxidation device

PendingCN111661901AEfficient removalNot prone to foulingSpecific water treatment objectivesWater/sewage treatment with mechanical oscillationsCatalytic oxidationMechanical engineering

The invention provides an electrocatalytic oxidation device. The device comprises a tank body, a cathode electrode and an anode electrode are arranged in the tank body, and a power supply is arrangedoutside the tank body; an air outlet is formed in the top of the side surface of the tank body and is connected with an air outlet pipeline, and the tail end of the air outlet pipeline is connected with an exhaust fan; a push plate is arranged at the end, away from the air outlet, in the tank body, the bottom of the push plate is higher than the upper surfaces of the cathode electrode and the anode electrode, a bottom plate is vertically and slidably connected to the push plate, the upper surface of the bottom plate is a sliding slope inclining downwards from the side close to the push plate,and a limiting block for limiting falling of the bottom plate is arranged at the bottom of the push plate; a driving mechanism for driving the push plate to move towards the air outlet is mounted on the tank body, a guide block is fixed at one end, close to the air outlet, of the inner side of the tank body and provided with a guide slope obliquely extending downwards from the bottom of the air outlet, and the lowermost end of the guide slope is located below the limiting block; and the lower surface of the air outlet pipeline is connected with a discharging pipe, and the discharging pipe is sleeved with a material receiving box which seals a pipe opening of the discharging pipe. Dross generated in the electrolysis process can be rapidly removed.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH +1

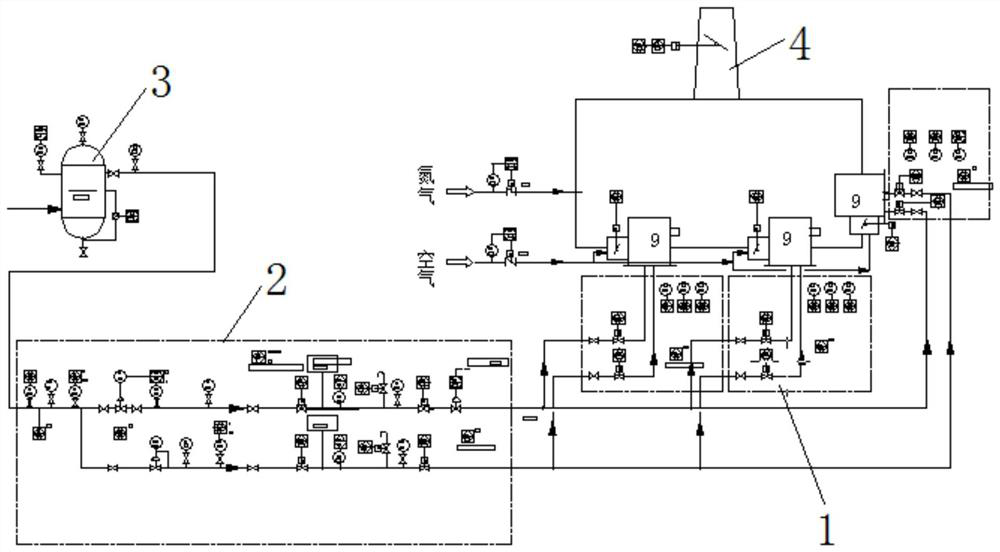

Safety disposal method and device for exhaust waste gas of petrochemical wastewater treatment plant

InactiveCN108144436ANo risk of explosionWater quality monitoringDispersed particle separationSimultaneous control of multiple variablesWater detectorCombustible gas

The invention relates to a safety disposal method and device for an exhaust waste gas of a petrochemical wastewater treatment plant. With respect to the characteristics of waste gases of different emission sources of a petrochemical wastewater treatment plant, an oil and water detector, an exhaust interlocking control valve, a combustible gas concentration monitor, gas replacement equipment and the like are arranged to perform monitoring and interlocking control on abnormal working conditions, so that long-term stable running of a waste gas disposal device is guaranteed, explosion risks and potential safety hazards are avoided, and stable, efficient and safe disposal of the exhaust waste gas of the petrochemical wastewater treatment plant is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

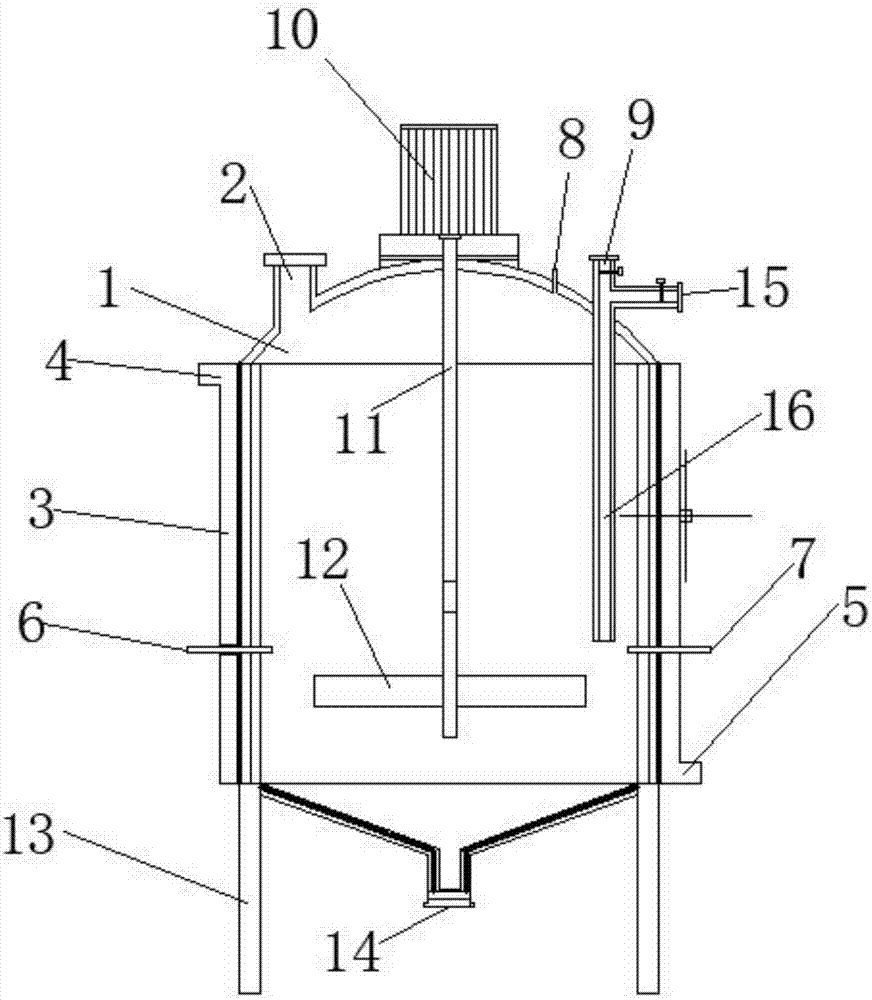

Liquid drug reaction kettle

InactiveCN107570103AIncrease concentrationImprove efficiencyChemical/physical/physico-chemical stationary reactorsFeed devicesHeating oilBiochemical engineering

The invention discloses a liquid drug reaction kettle and belongs to the technical field of a reaction kettle. The liquid drug reaction kettle comprises a shell, wherein a first material feeding opening is formed in the left part of the top end of the shell; a motor is arranged at the top end of the shell; a stirring rod is arranged at the bottom end of an output shaft of the motor; two sets of stirring blades are arranged on the outer wall of the lower part of the stirring rod; a manifold and a decompressing valve are arranged on the right part of the top end of the shell; the decompressing valve is located on the left part of the manifold; a second material feeding opening is formed at the top end of the manifold; a liquid pumping opening is formed on the outer wall of the right end of the upper part of the manifold; a jacket is arranged on the outer wall of the lower part of the shell; a heating oil inlet and a heating oil outlet are formed on the upper part of the left end and thelower part of the right end of the jacket, respectively; a temperature sensor and a pressure sensor are arranged on the lower parts of the left and right ends of the shell, respectively; a dischargingopening is formed at the bottom end of the shell; supporting frames are arranged at four corners of the bottom end of the shell. A second material stock solution feeding opening is formed on the liquid drug reaction kettle.

Owner:湖北同盛网络科技有限公司

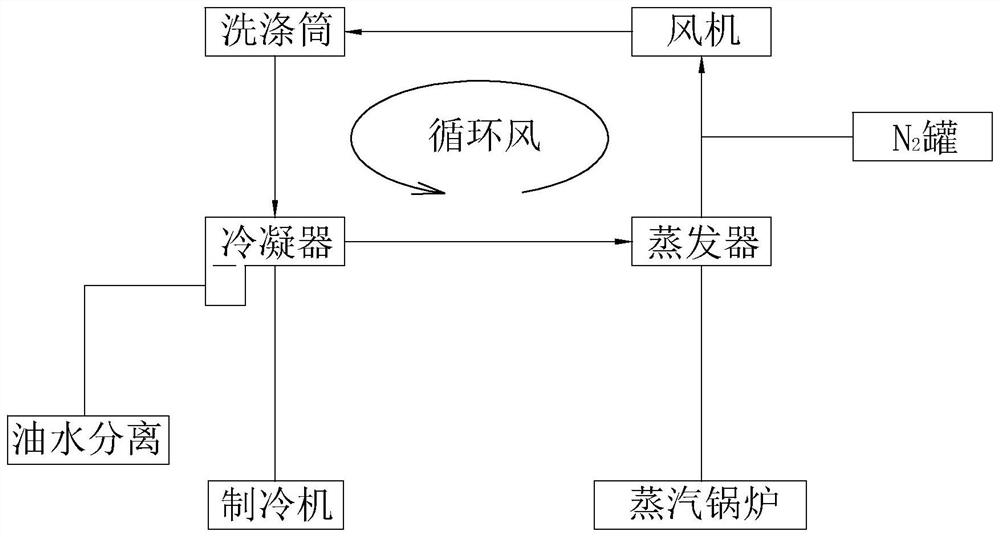

Active safety detection method for dry cleaning machine

InactiveCN113089275AAvoid flash explosionAchieving Active Explosion SafetyDry-cleaning apparatusTextiles and paperEnvironmental engineeringNitrogen gas

The invention discloses an active safety detection method for a dry cleaning machine. A dry cleaning solvent concentration detection sensor detects the concentration of steam in a drying circulating air duct or a washing drum and controls the opening and closing of a nitrogen supplementing device and / or an electronic safety valve through an electric signal; the nitrogen supplementing device and / or the electronic safety valve are / is mounted in the drying circulating air duct; moreover, in a drying procedure, the dry cleaning solvent concentration detection sensor detects the concentration value of dry cleaning solvent steam in the drying circulating air duct; and the nitrogen supplementing device is controlled to be started and stopped according to comparison between the steam concentration with a first threshold value A and a second threshold value B. The nitrogen supplementing device and the dry cleaning solvent concentration detection sensor are arranged in the drying circulating air duct, so that the functions of automatic concentration detection and automatic nitrogen supplementing are achieved; the method belongs to an active intervention safety measure; the active anti-explosion safety of the dry cleaning machine with the drying function is achieved; and the method is an active safety measure.

Owner:济南汇捷智能科技有限公司

Naphthalene tank breathing valve enhanced cooling crystallization scraping device

InactiveCN105819124BAvoid crystal pluggingGuaranteed to workLarge containersNeedle roller bearingBreather

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

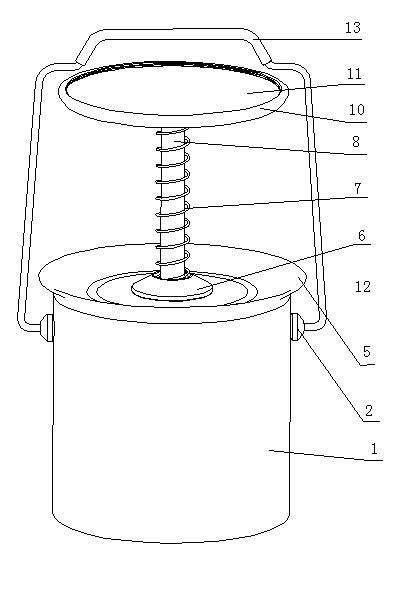

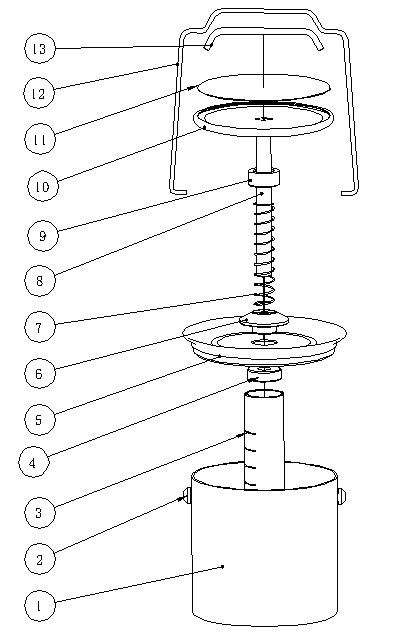

Portable gasoline economizer

InactiveCN101811606BNot prone to spillagePrevent volatilizationDispensing apparatusAutomatic controlBiochemical engineering

The invention relates to a portable gasoline economizer which belongs to the field of rubber processing devices. The portable gasoline economizer is provided with a cylindrical gasoline reservoir and a cover plate, wherein a tubular gasoline conveyor is fixed in the gasoline reservoir, a notch is arranged on the pipe wall of the gasoline conveyor, a piston is arranged in the gasoline conveyor, the lower end of an gasoline pipe passes through a through hole at the middle part of the cover plate and screwed with a screw hole at the middle part of the piston together, a nut is fixed at the upperpart of the gasoline pipe, a spring is sleeved on the gasoline pipe and limited between the nut and the cover plate, and the top end of the gasoline pipe is screwed in the screw hole at the middle part of a gasoline tray. The invention is simple in structure, easy to operate and convenient to carry, can automatically control the gasoline output quantity, automatically recover redundant gasoline, effectively prevent static and gasoline flash exposition, quantitively control the single gasoline quantity, reduce the gasoline loss, reach the gasoline utilization ratio up to more than 96 percent, is convenient for gasoline charge and simple in operation.

Owner:WEIHAI BAISHENGDA MACHINERY EQUIP

Method for oxidizing ferrous sulfide into elemental sulfur and ferric oxide

InactiveCN106241748ASpeed up the flowUniform and stable oxidation temperatureSulfur preparation/purificationFerric oxidesBlack ferric oxideOxidative treatment

The invention provides a method for oxidizing ferrous sulfide into elemental sulfur and ferric oxide. The method comprises the following steps of adding water to the ferrous sulfide, and preparing a sizing agent, wherein the mass percentage concentration of the ferrous sulfide is 1-79.9%; performing oxidation treatment on the sizing agent, wherein the oxidizing time is 0.3-50h, sufficiently mixing the sizing agent in an oxidation process, and always controlling the temperature of the sizing agent to be 60-99.9 DEG C; and preparing the ferric oxide and the elemental sulfur. The technical scheme provided by the invention has the advantages of being low in cost, and developed in used equipment, and solves the problem that the temperature in the oxidation technology process of the ferrous sulfide is difficult to control. The used equipment can meet time requirements required for oxidization of the ferrous sulfide, and the method has high use values and high economic values.

Owner:刘慧南

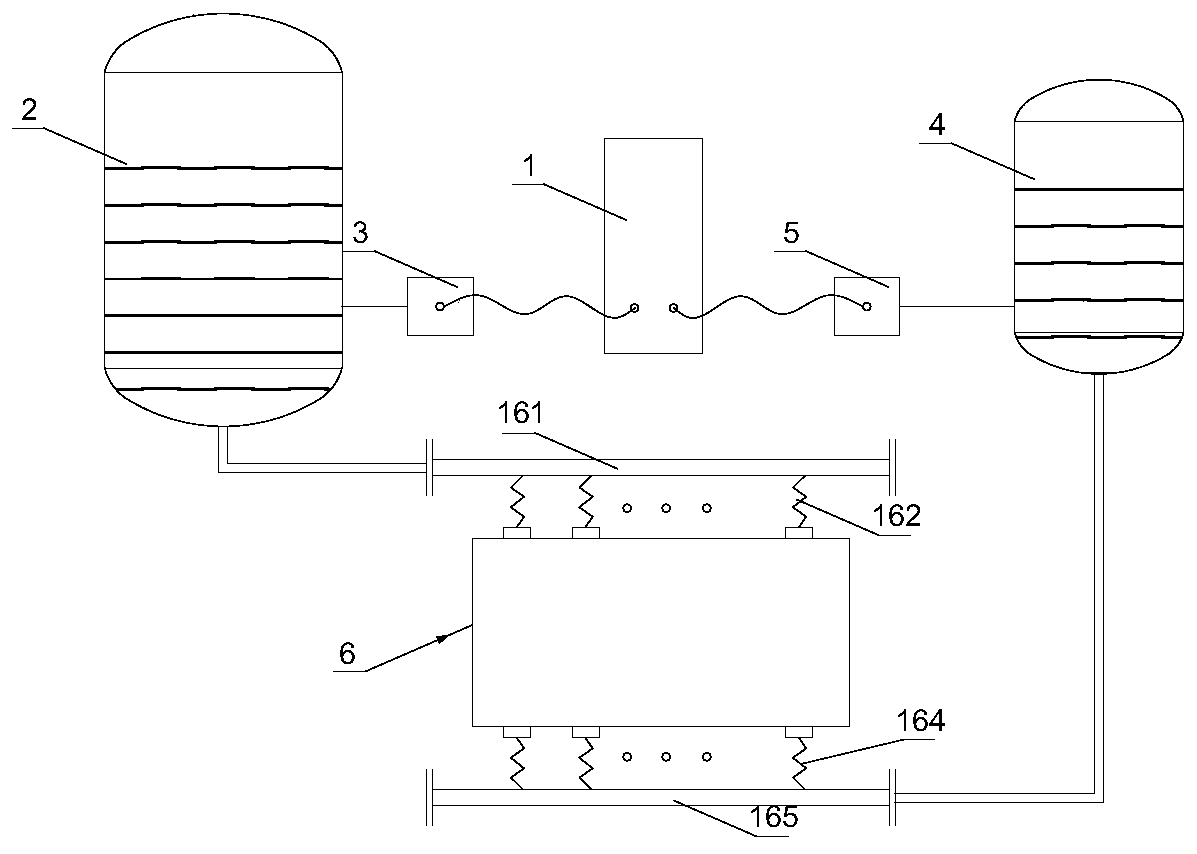

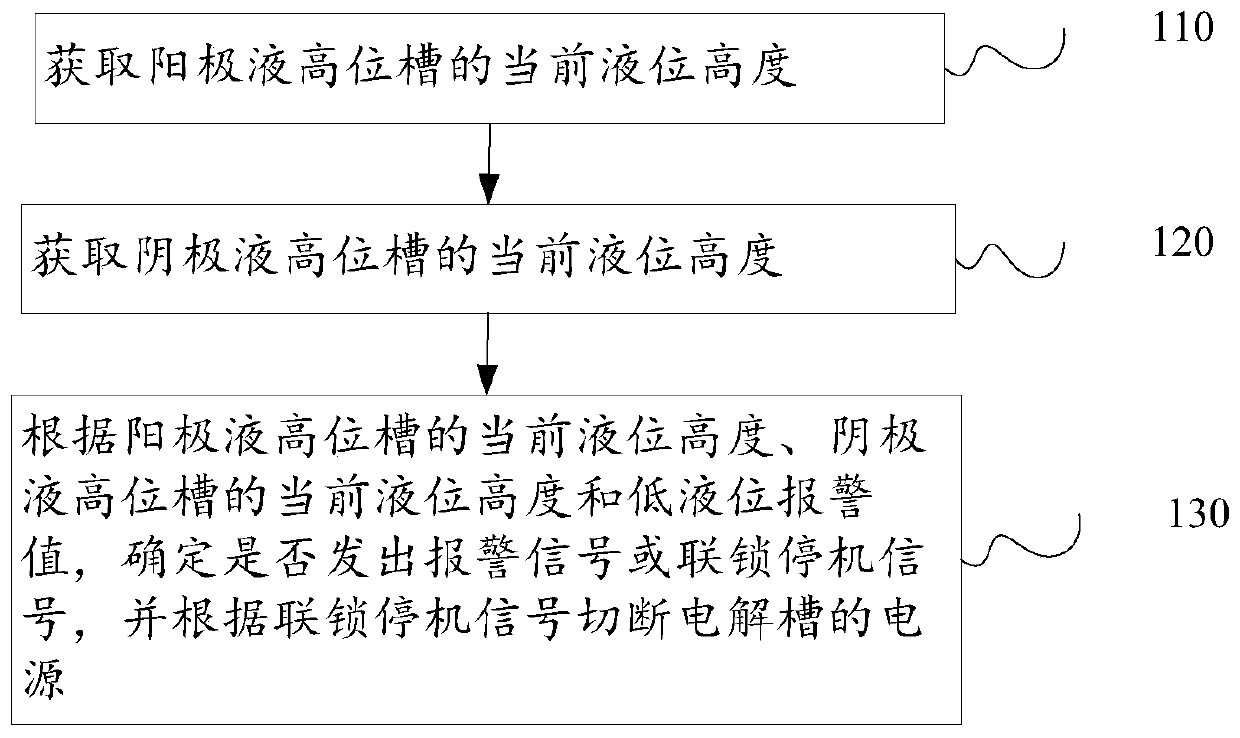

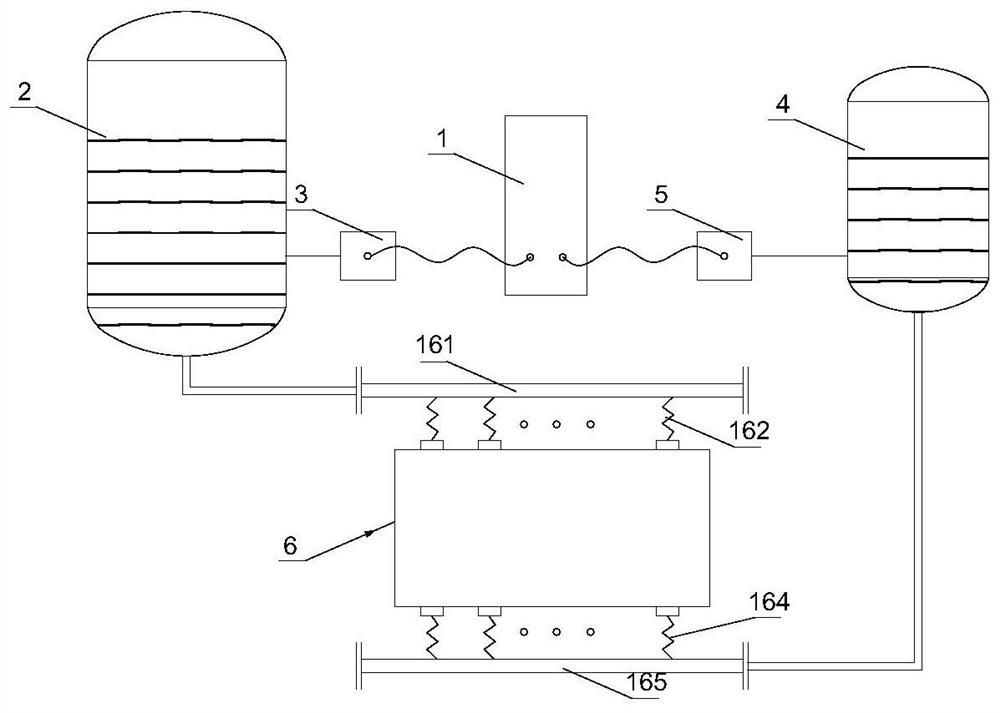

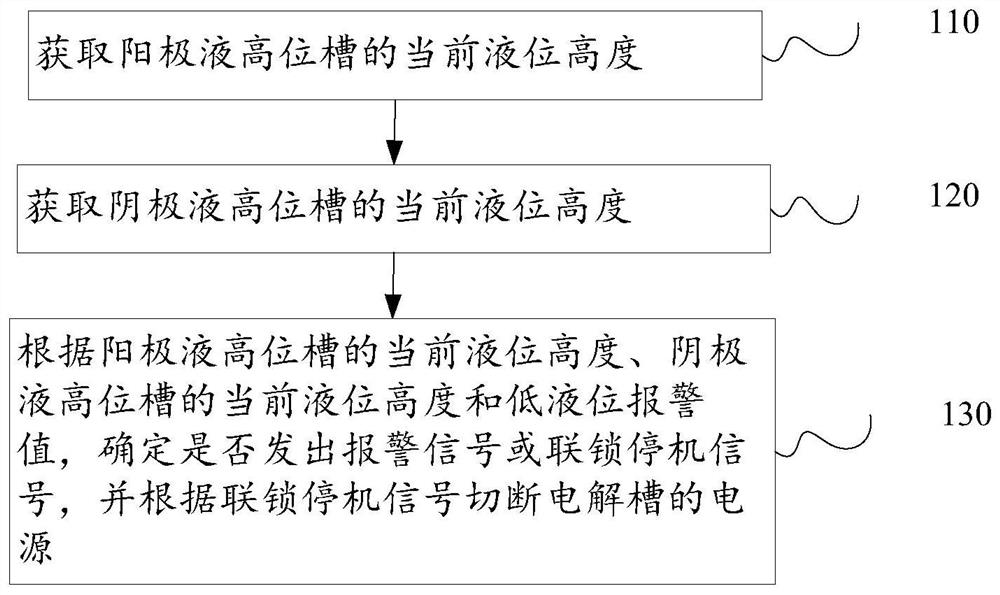

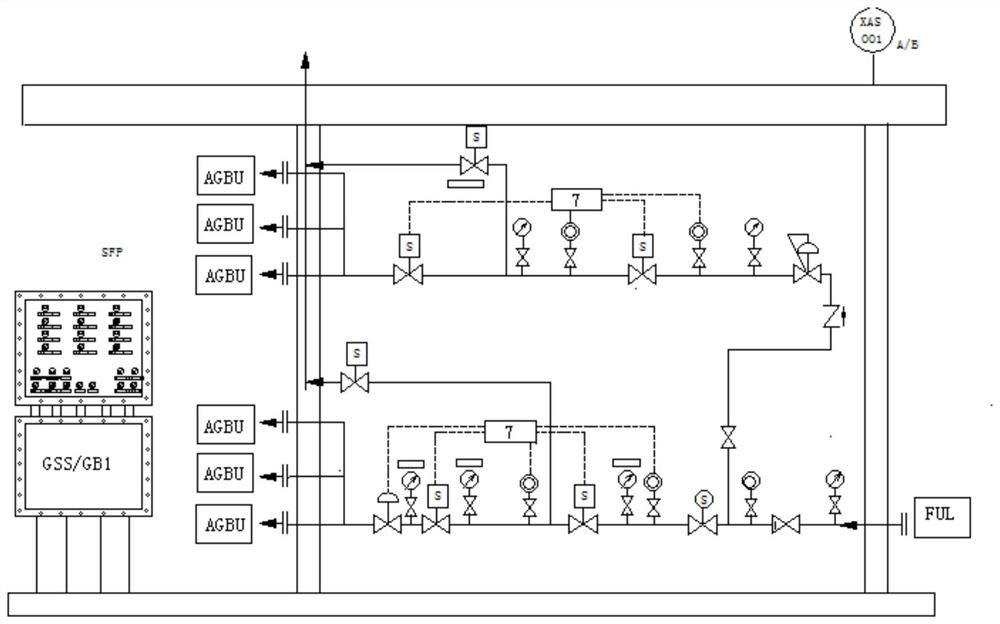

An electrolytic tank interlock shutdown system and method

ActiveCN111501063AEnsure safetyFor quick replacementElectrolysis componentsControl cellProcess engineering

The invention relates to an electrolytic tank interlock shutdown system and method; the system comprises a control unit, a first height sensor, a second height sensor, an anolyte elevated tank, a catholyte elevated tank, an electrolytic tank and a pipeline system, and the anolyte elevated tank and the catholyte elevated tank are connected with the electrolytic tank through the pipeline system; thecontrol unit is respectively connected with the first height sensor and the second height sensor, and is used for determining whether to send out an alarm signal or an interlocking shutdown signal according to the current liquid level height of the anolyte elevated tank, the current liquid level height of the catholyte elevated tank and the low liquid level alarm value, and cutting off the powersupply of the electrolytic tank according to the interlocking shutdown signal. The invention ensures the safety of the electrolytic tank after the interlocking shutdown is triggered.

Owner:新疆中泰创新技术研究院有限责任公司 +1

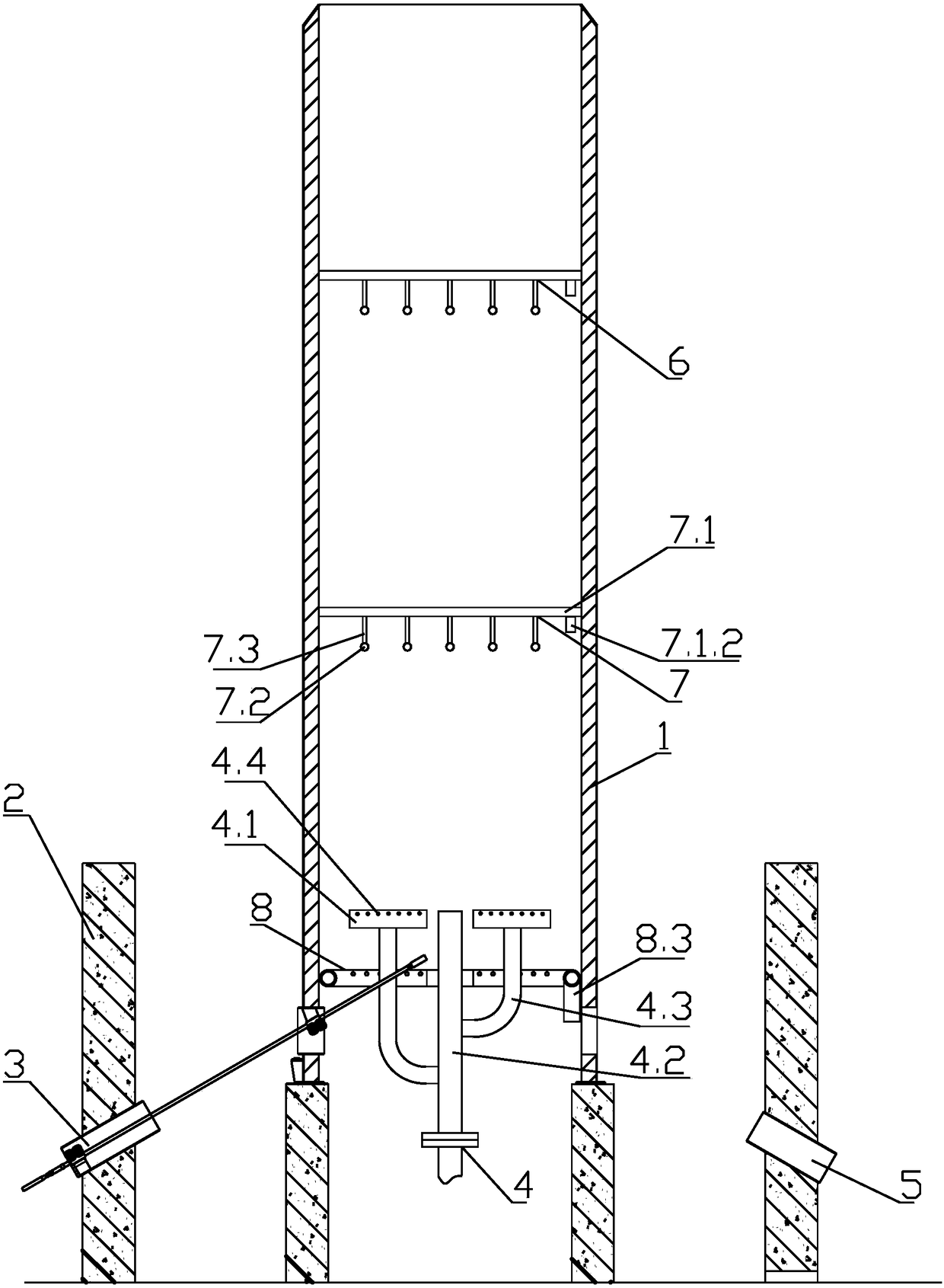

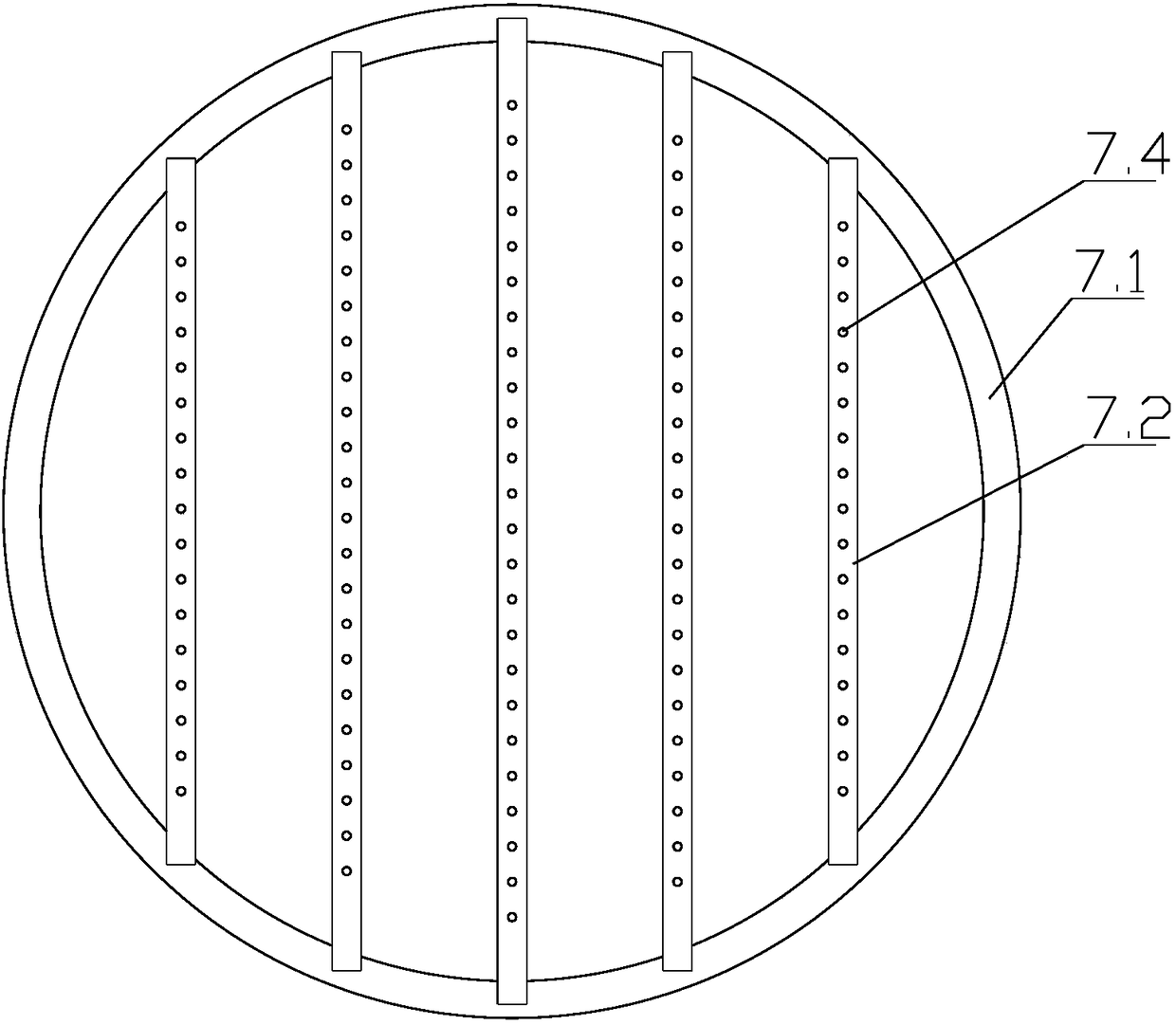

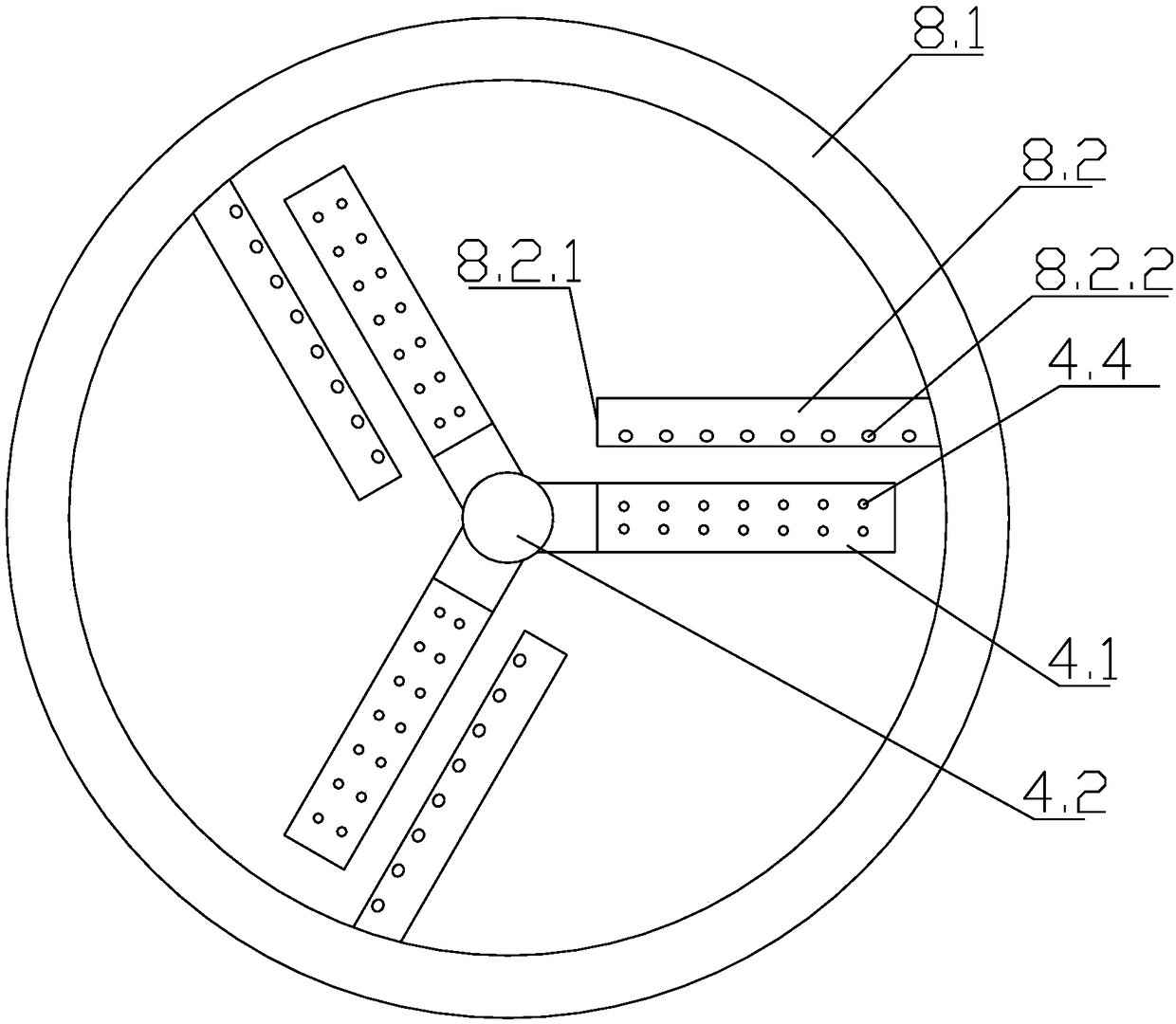

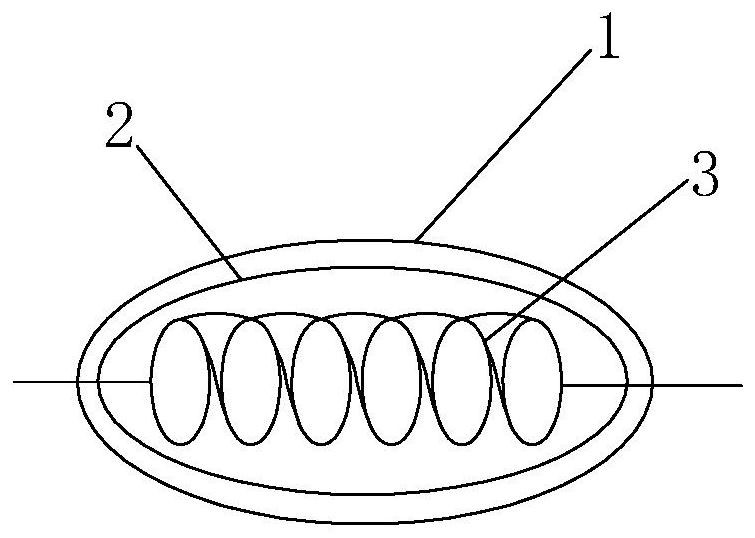

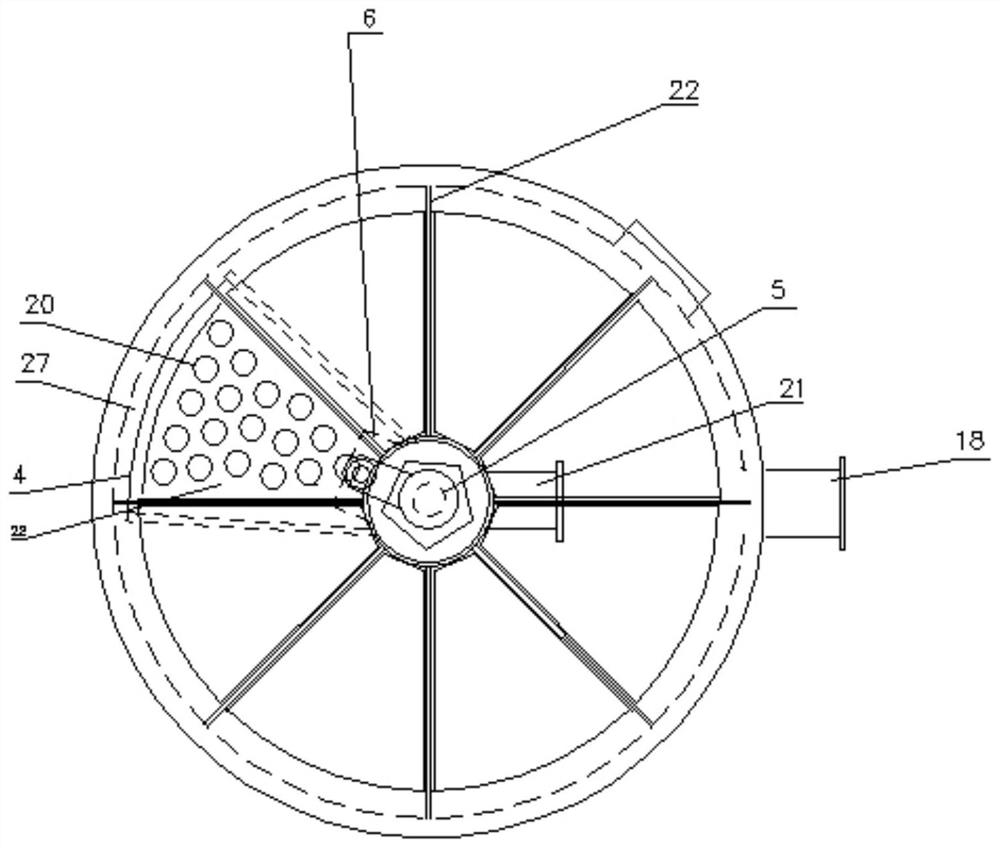

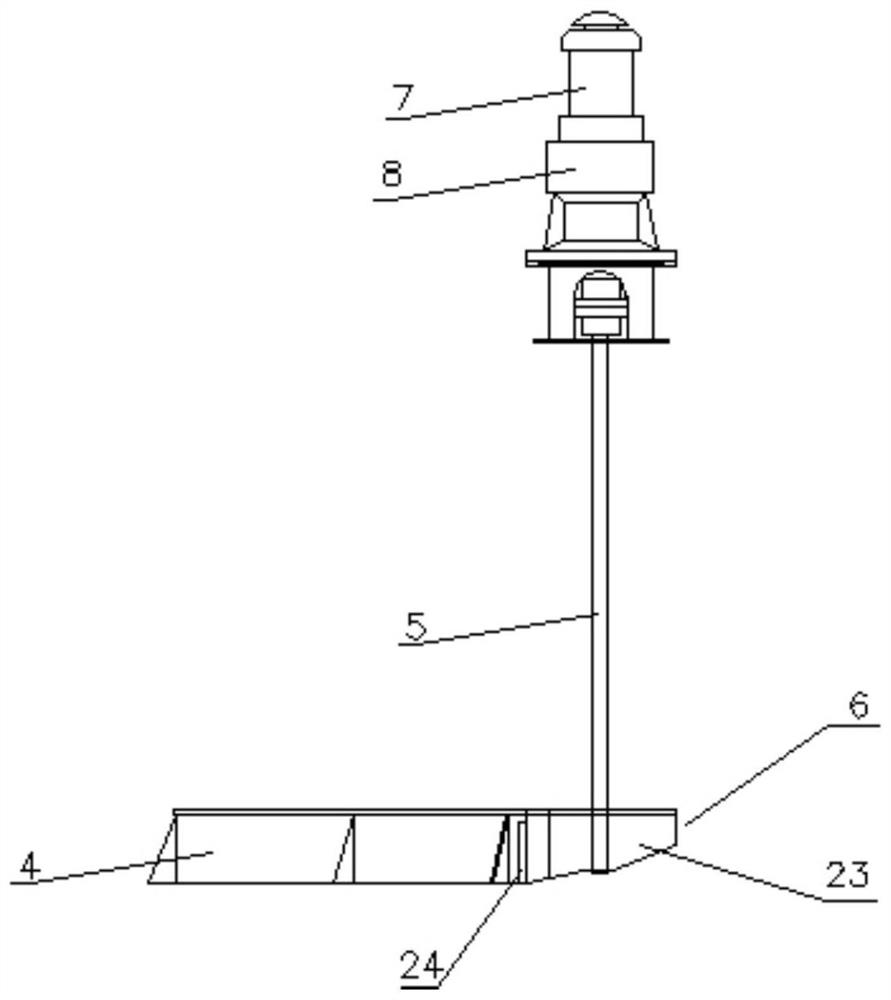

A jacketed multi-circuit naphthalene forced crystallization recovery device

InactiveCN106215452BAvoid crystal pluggingGuaranteed to workSolution crystallizationHeat exchange cooling cystallizationMotor driveNaphthalene

The invention relates to a jacketed multi-loop naphthalene forced crystallization and recycling apparatus, comprising a barrel, a multi-layer screen tube, a grid plate, a needle bearing, an O-shaped belt, a pulley, and a reduction motor; the needle bearing is mounted at the bottom of the barrel, a shaft lever of the grid plate is mounted in the needle bearing, the grid plate and the multi-layer screen tube are nested in a staggered manner to form a multi-loop structure; a fastening structure is provided between the bottom of the multi-layer screen tube and a bottom stand of the barrel to fix the barrel and the multi-layer screen tube; the reduction motor drives the grid plate to rotate through the o-shaped belt; the grid plate is fitted with a brush, the brush comes in frictional contact with the surface of the multi-layer screen tube when the grid plate rotates to scrape off crystal that falls into a tank. The jacketed multi-loop naphthalene forced crystallization and recycling apparatus as an auxiliary device to a naphthalene tank breather valve and is mounted between a naphthalene tank and the breather valve through a reducing flange to carry out naphthalene forced cooling and crystallization and scrape off the crystal into the tank; the jacketed multi-loop naphthalene forced crystallization and recycling apparatus is simple in structure and is easy to implement, and the problem of the prior art that naphthalene crystal blocks the top breather valve of a naphthalene storage tank is solved.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

An electrolyzer interlock parking system and method

ActiveCN111501063BEnsure safetyGuaranteed liquid levelElectrolysis componentsControl cellControl theory

Owner:新疆中泰创新技术研究院有限责任公司 +1

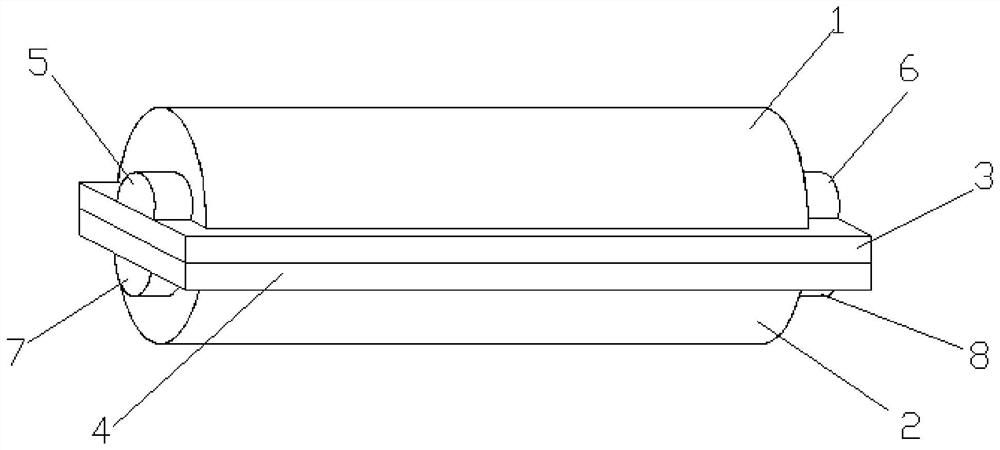

Pull-in type cable explosion-proof box

PendingCN113161976APrevent water from entering through pipesAvoid flash explosionCable junctionsCable inlet sealing meansPower cableStructural engineering

The invention provides a pull-in type cable explosion-proof box. The pull-in type cable explosion-proof box comprises an upper explosion-proof shell and a lower explosion-proof shell; the upper explosion-proof shell and the lower explosion-proof shell are solid semi-cylinders; the outer sides of the upper and lower rectangular binding surfaces are respectively provided with upper and lower cover magnetic layers, and the upper and lower explosion-proof shells are attracted through the upper and lower cover magnetic layers to form a cylindrical shape; two ends of the upper explosion-proof shell and the lower explosion-proof shell are respectively provided with a flexible sealing assembly; and a cable penetrating pipe extrudes and penetrates through the upper and lower flexible sealing assemblies and the joint of the upper cover magnetic layer and the lower cover magnetic layer, and a first sealing cavity, a penetrating pipe containing cavity and a second sealing cavity are formed in sequence. The pull-in type cable explosion-proof box provided by the invention meets the waterproof and explosion-flashover-proof requirements of a power cable, effectively prevents water from entering the cable through a pipe, avoids the flash explosion caused by the cable being affected with damp, and guarantees the safe operation of a power distribution network.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO QINGZHOU POWER SUPPLY CO +2

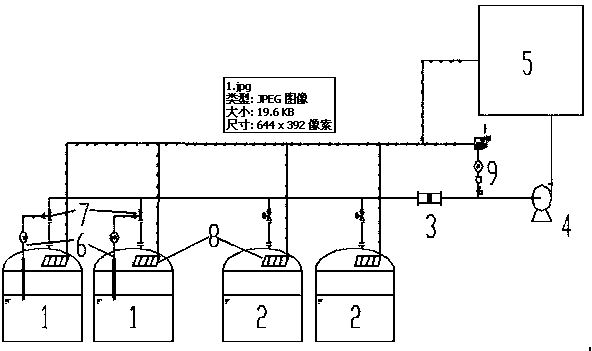

Safety control method of storage tank VOCs discharging open flame equipment

The invention relates to the technical field of normal-pressure and low-pressure storage tank volatile organic compound safe collecting and discharging, and discloses a safety control method of storage tank VOCs discharging open flame equipment. The safety control method comprises the following steps of classifying and collecting of a storage tank group VOCs with various materials, communicating treatment of the storage tank VOCs with the same or similar materials, nitrogen sealing measure treatment of safe control of the storage tank group with various materials, discharging open flame equipment treatment of storage tank group VOCs with various materials and oxygen content measure treatment and emergency emptying measure treatment of safe control of the open flame equipment. According tothe safety control method, the gas-phase space of the storage tank can be effectively controlled to avoid forming an explosive environment, so that the risk of fire disasters in the storage tanks is reduced, moreover, an explosive gas can be prevented from being formed in a front pipeline of the open flame equipment to the largest extent, so that the absolute safety of open flame equipment is ensured. Meanwhile, the safety control method also realizes the treatment of the various material storage tank VOCs.

Owner:CHINA PETROLEUM & CHEM CORP +1

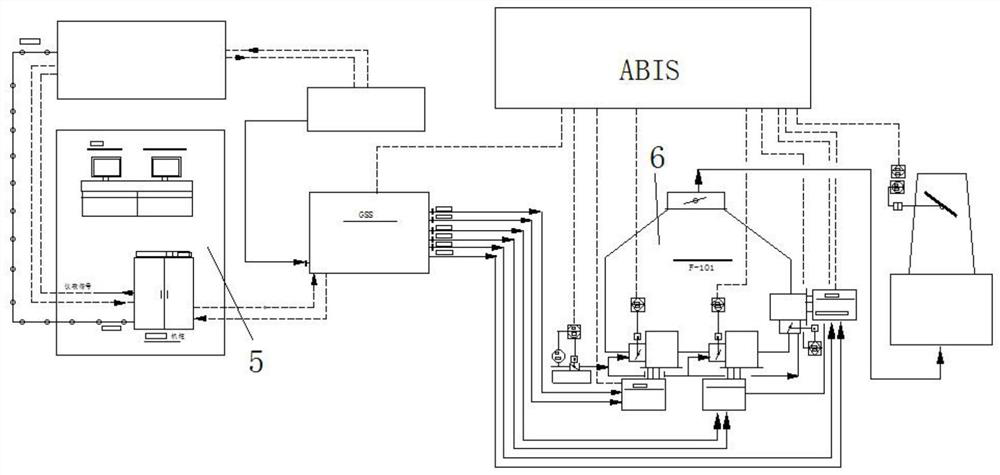

Refined control method of industrial combustion furnace

ActiveCN106196065BRealize regulationIncrease contact areaGaseous fuel burnerControl flowCombustion chamber

Owner:CHINA PETROLEUM & CHEM CORP +1

Portable gasoline economizer

InactiveCN101811606ANot prone to spillagePrevent volatilizationDispensing apparatusAutomatic controlBiochemical engineering

The invention relates to a portable gasoline economizer which belongs to the field of rubber processing devices. The portable gasoline economizer is provided with a cylindrical gasoline reservoir and a cover plate, wherein a tubular gasoline conveyor is fixed in the gasoline reservoir, a notch is arranged on the pipe wall of the gasoline conveyor, a piston is arranged in the gasoline conveyor, the lower end of an gasoline pipe passes through a through hole at the middle part of the cover plate and screwed with a screw hole at the middle part of the piston together, a nut is fixed at the upper part of the gasoline pipe, a spring is sleeved on the gasoline pipe and limited between the nut and the cover plate, and the top end of the gasoline pipe is screwed in the screw hole at the middle part of a gasoline tray. The invention is simple in structure, easy to operate and convenient to carry, can automatically control the gasoline output quantity, automatically recover redundant gasoline, effectively prevent static and gasoline flash exposition, quantitively control the single gasoline quantity, reduce the gasoline loss, reach the gasoline utilization ratio up to more than 96 percent, is convenient for gasoline charge and simple in operation.

Owner:WEIHAI BAISHENGDA MACHINERY EQUIP

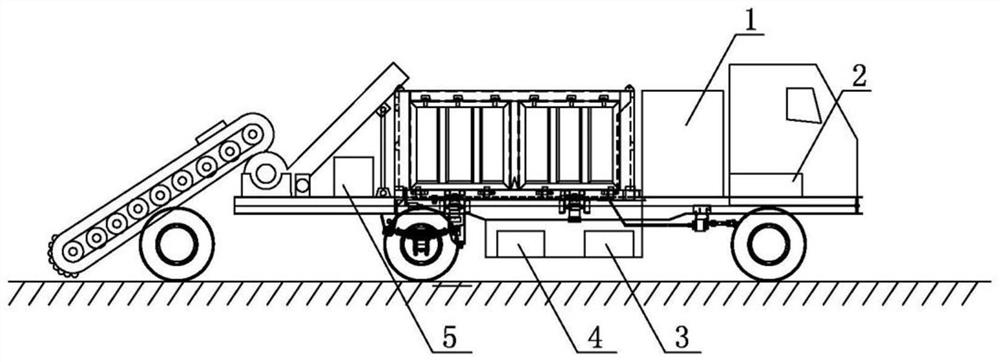

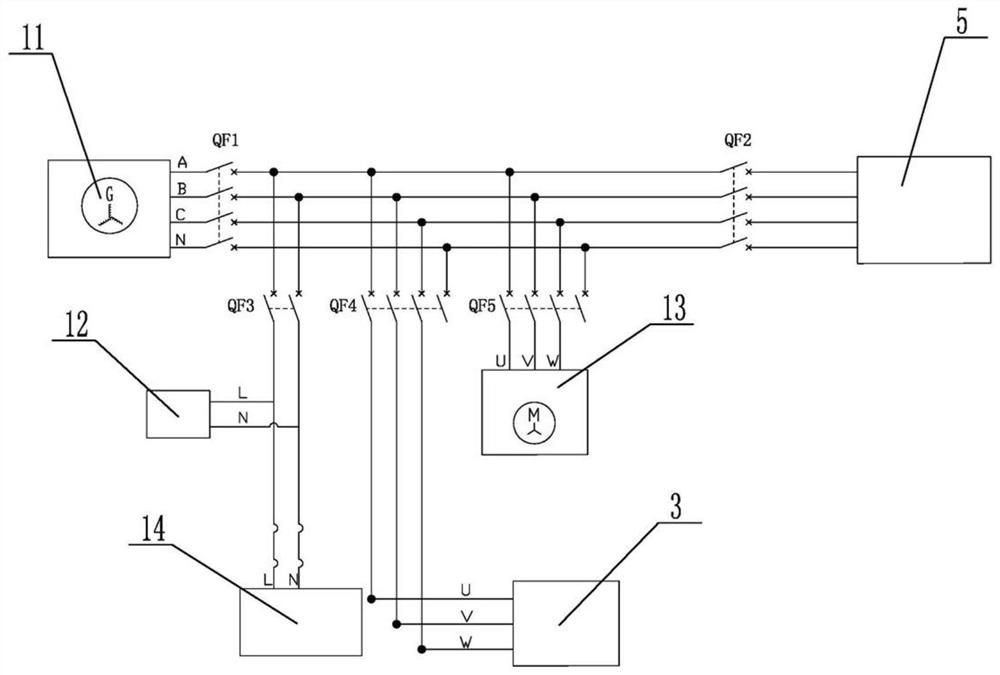

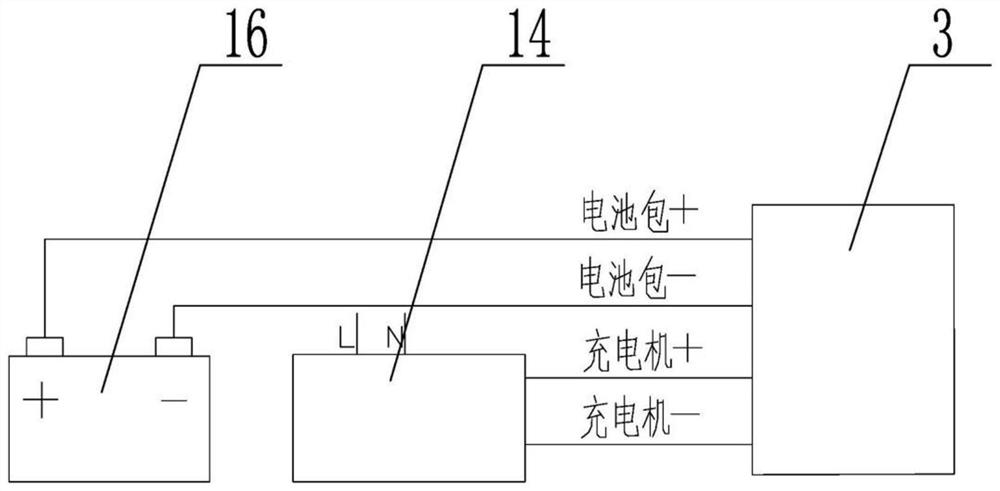

High-voltage control system of tunnel marine organism collecting vehicle

PendingCN112193139AImprove reliabilityAvoid corrosionNuclear energy generationMachines/enginesContactorElectric generator

The invention discloses a high-voltage control system of a tunnel marine organism collection vehicle, which comprises a plurality of high-voltage control units respectively packaged in different box bodies of a protection level IP67 according to different functions, and each high-voltage control unit comprises a diesel generator unit, a power battery unit, a high-voltage control cabinet unit, a motor controller unit and a collection device control box unit; the beneficial effects of the invention are that all high-voltage control parts are respectively packaged in different box bodies with theprotection level of IP67 according to different functions, thereby forming all high-voltage control units, enabling all control units to be connected through cables with quick connectors, and avoiding the corrosion of a system caused by the moisture of marine organisms in a tunnel; a quick charging loop and a slow charging loop are integrated into one circuit, and a charging contactor K4 and a charging contactor K5 are set to be in a one-on-one-off structural form, so that the problem of flash explosion of hydrogen sulfide and ammonia gas in a tunnel caused by electric sparks generated by switching the quick charging loop and the slow charging loop when the circuit is not discharged thoroughly is avoided.

Owner:济宁中科智能科技有限公司

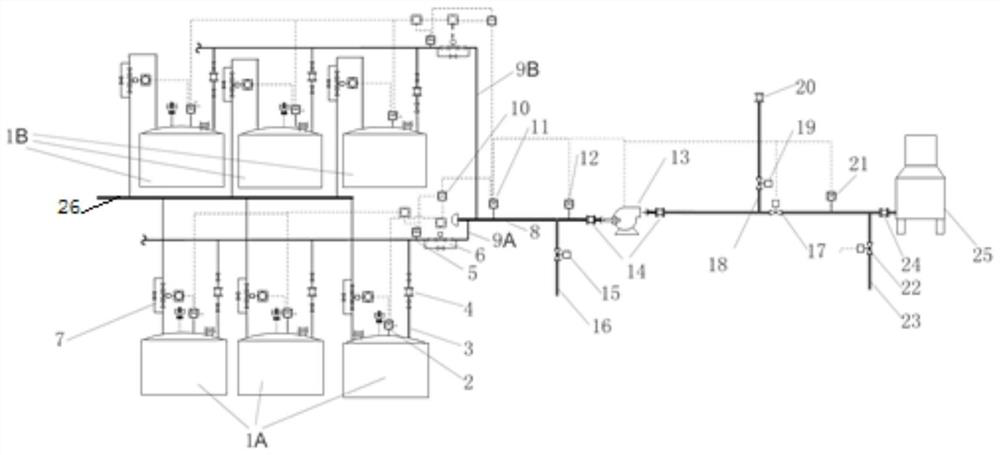

Safety device for storage tank vocs discharge open flame equipment

ActiveCN110143380BReduce big breathEmission reductionLarge containersFire - disastersSuction equipment

The invention relates to the safety technical field of normal-pressure and low-pressure storage tank volatile organic compound safe collecting and discharging open flame equipment, and discloses a safety device of the storage tank VOCs discharging open flame equipment. The safety device comprises a storage tank group of a plurality of materials, gas extraction equipment and the open flame equipment. According to the safety device, the gas-phase space of storage tanks can be effectively controlled to prevent an explosive environment from being formed, so that the risk of fire disasters in the storage tanks is reduced; moreover, forming of explosive gas in a pipeline before entrance into the open flame equipment can be dually prevented, so that the absolute safety of the open flame equipmentis ensured. Meanwhile, the safety device also realizes the treatment of various material storage tank VOCs.

Owner:CHINA PETROLEUM & CHEM CORP +1

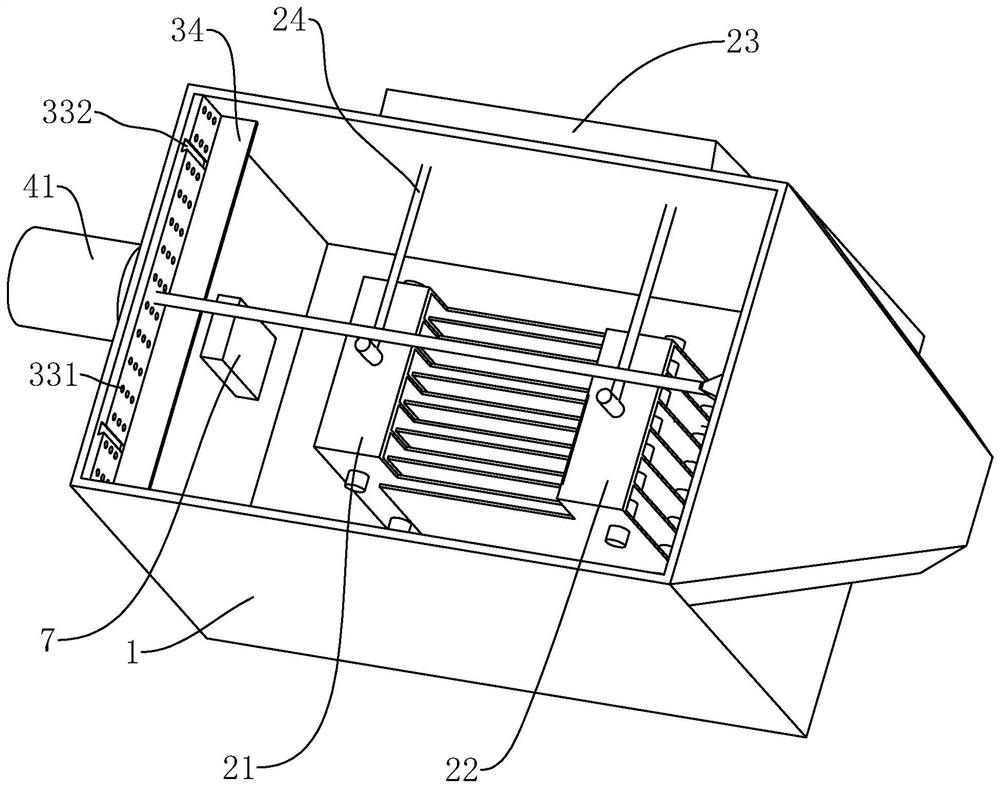

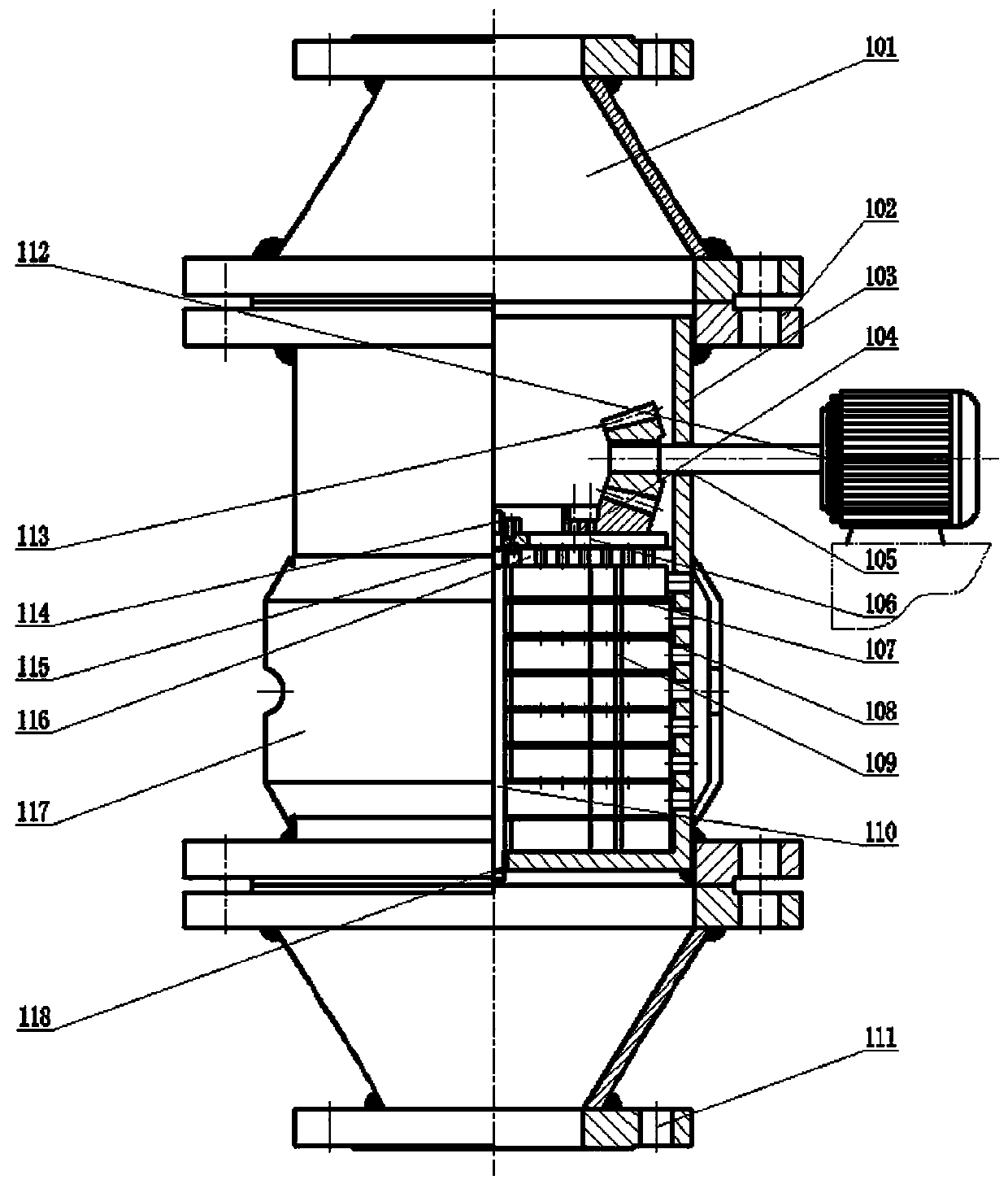

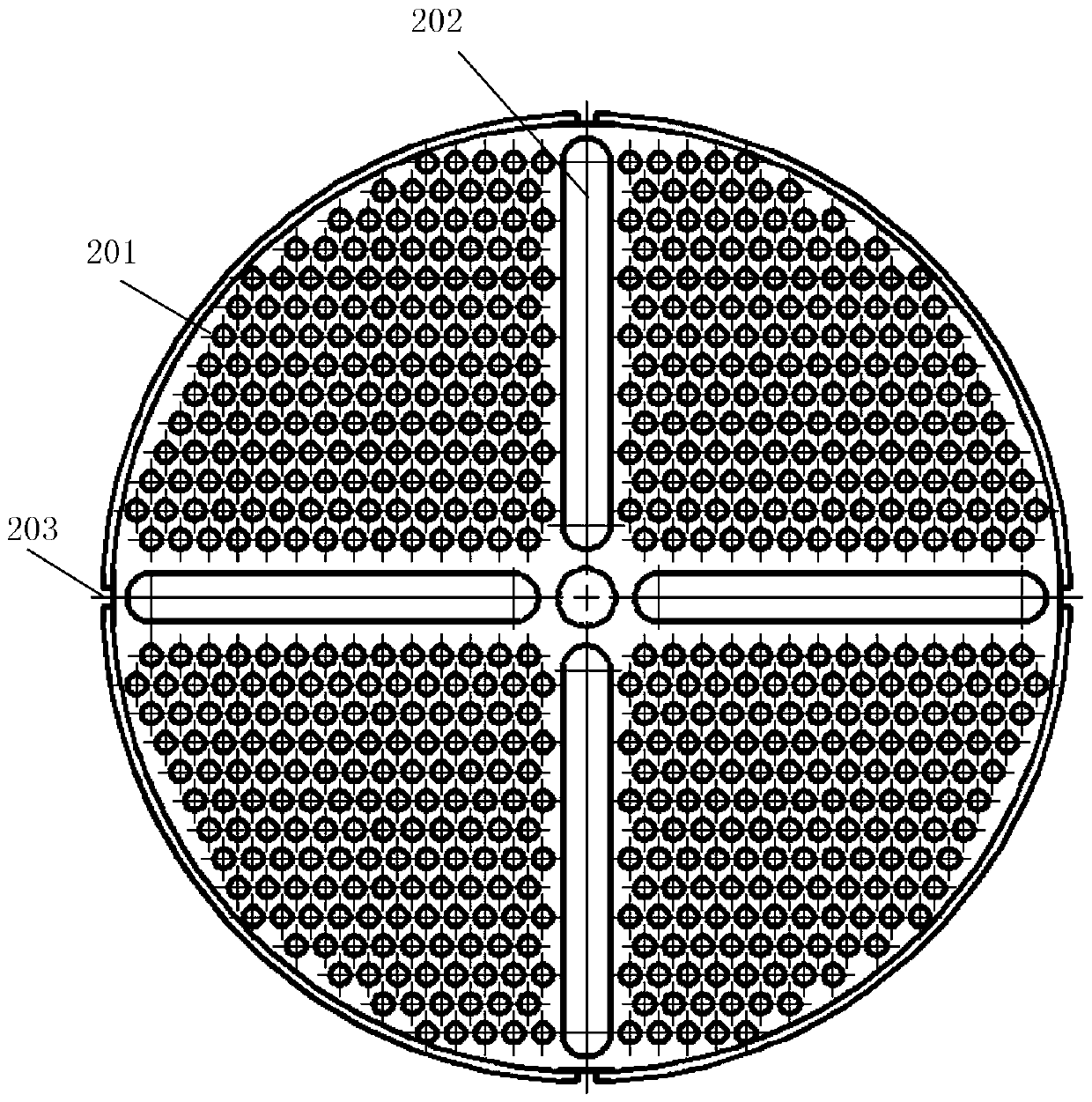

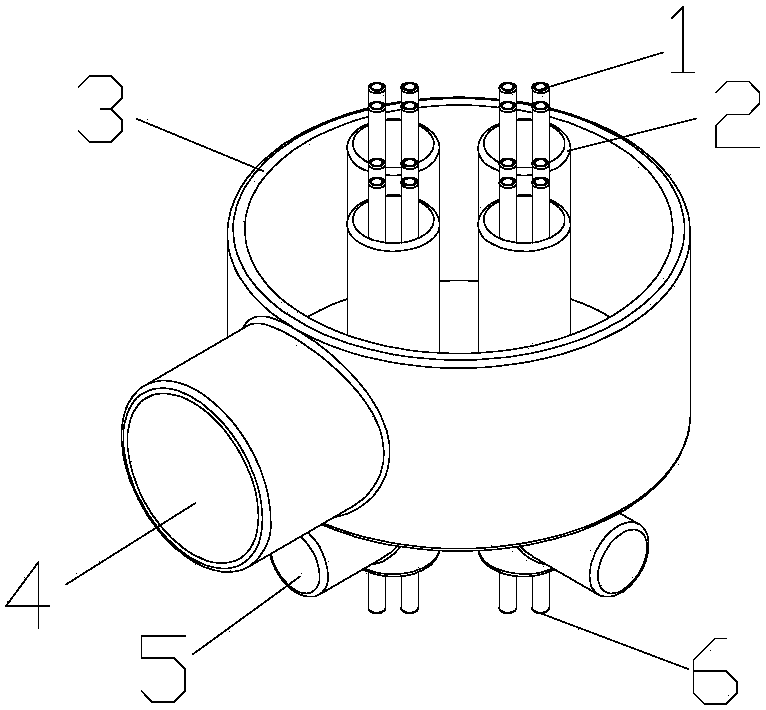

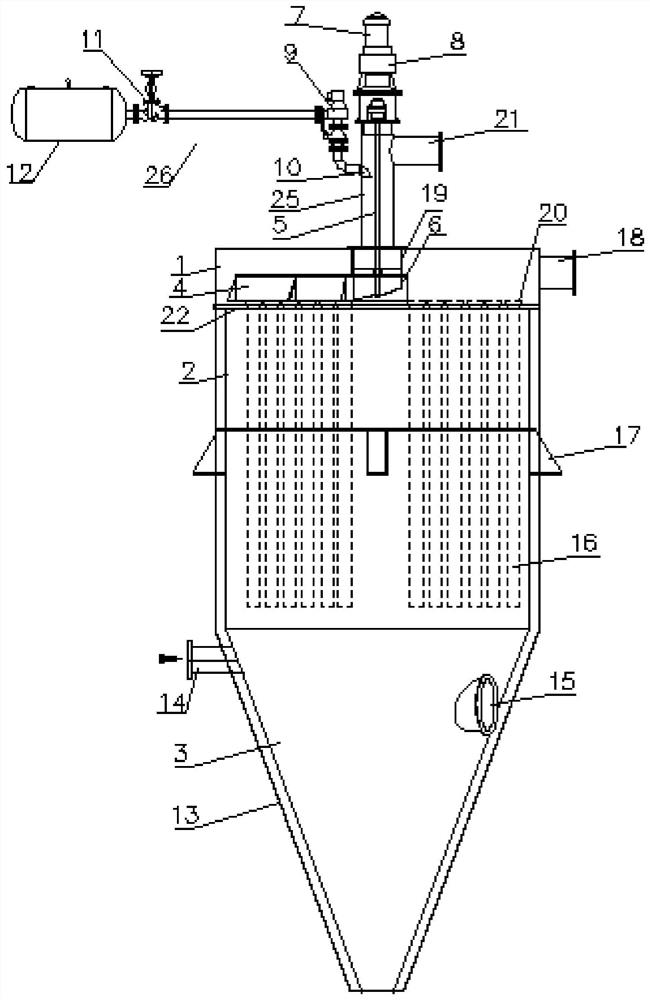

Special pulse bag-type dust collector for purifying tail gas of closed submerged arc furnace

PendingCN114669130ASave nitrogen resourcesAvoid flash explosionDispersed particle filtrationExhaust gasEngineering

A special pulsed jet cloth filter for tail gas purification of a closed submerged arc furnace comprises an upper box body, a middle box body and an ash bucket, the upper end of the middle box body and the lower end of the upper box body are communicated through a pattern plate and a filter bag, the lower end of the middle box body is communicated with the upper end of the ash bucket, the upper box body and the middle box body are both of a cylindrical structure, and the ash bucket is of a conical structure. An ash removal rotating cover and an ash removal rotating nozzle are arranged in the upper box body and fixed to the lower end of the rotating shaft, a pipe shaft of an ash removal back-blowing pipe is perpendicular to the upper end face of the upper box body and arranged in the center of the upper box body, the ash removal back-blowing pipe is communicated with the upper box body, and a gear motor is fixed to the upper end of the ash removal back-blowing pipe in a sealed mode. The left side of the ash-cleaning back-blowing pipe is communicated with an ash-cleaning spray pipe of the nitrogen ash-cleaning device, the right side of the ash-cleaning back-blowing pipe is communicated with a gas conveying pipe of a back-blowing system, the overlook structure of the ash-cleaning rotary cover is fan-shaped or circular, and a surrounding plate perpendicular to the fan-shaped or circular surface is arranged on the periphery of the fan-shaped or circular surface.

Owner:湖北江环环保科技有限公司

Safety control method for storage tank vocs discharge open flame equipment

ActiveCN110143377BReduce big breathEmission reductionLarge containersFire rescueGas phaseFire - disasters

The invention relates to the technical field of normal-pressure and low-pressure storage tank volatile organic compound safe collecting and discharging, and discloses a safety control method of storage tank VOCs discharging open flame equipment. The safety control method comprises the following steps of classifying and collecting of a storage tank group VOCs with various materials, communicating treatment of the storage tank VOCs with the same or similar materials, nitrogen sealing measure treatment of safe control of the storage tank group with various materials, discharging open flame equipment treatment of storage tank group VOCs with various materials and oxygen content measure treatment and emergency emptying measure treatment of safe control of the open flame equipment. According tothe safety control method, the gas-phase space of the storage tank can be effectively controlled to avoid forming an explosive environment, so that the risk of fire disasters in the storage tanks is reduced, moreover, an explosive gas can be prevented from being formed in a front pipeline of the open flame equipment to the largest extent, so that the absolute safety of open flame equipment is ensured. Meanwhile, the safety control method also realizes the treatment of the various material storage tank VOCs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Intelligent gas burner ignition system

ActiveCN113915641AAvoid flash explosionPrevent inflowFire rescueCombustion ignitionProcess engineeringNitrogen gas

The invention discloses an intelligent gas burner ignition system, and relates to the technical field of burner ignition devices. The intelligent gas burner ignition system comprises a burner ignition part which is skid-mounted in one closed device and a fuel gas conveying part which is skid-mounted in the other closed device. The burner ignition part is provided with an intelligent ignition state tracking subsystem, an incandescent light ignition subsystem, a burner ignition subsystem, a nitrogen purging subsystem, a double-valve leak detection subsystem and a fire extinguishing subsystem. The fuel gas conveying part is provided with the double-valve leak detection subsystem. The fuel gas conveying part is used for conveying fuel gas to the burner ignition part. According to the intelligent burner ignition system disclosed by the invention, the ignition efficiency can be improved, and the safety in the ignition process is improved.

Owner:上海轻叶能源股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com