A jacketed multi-circuit naphthalene forced crystallization recovery device

A technology of forced crystallization and recovery device, applied in the direction of solution crystallization, heat exchange cooling crystallization, crystallization purification/separation, etc., can solve the problems of crystalline naphthalene blocking the breathing valve on the top of the naphthalene storage tank, and achieve simple structure, convenient gas circulation, The effect of preventing crystal blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

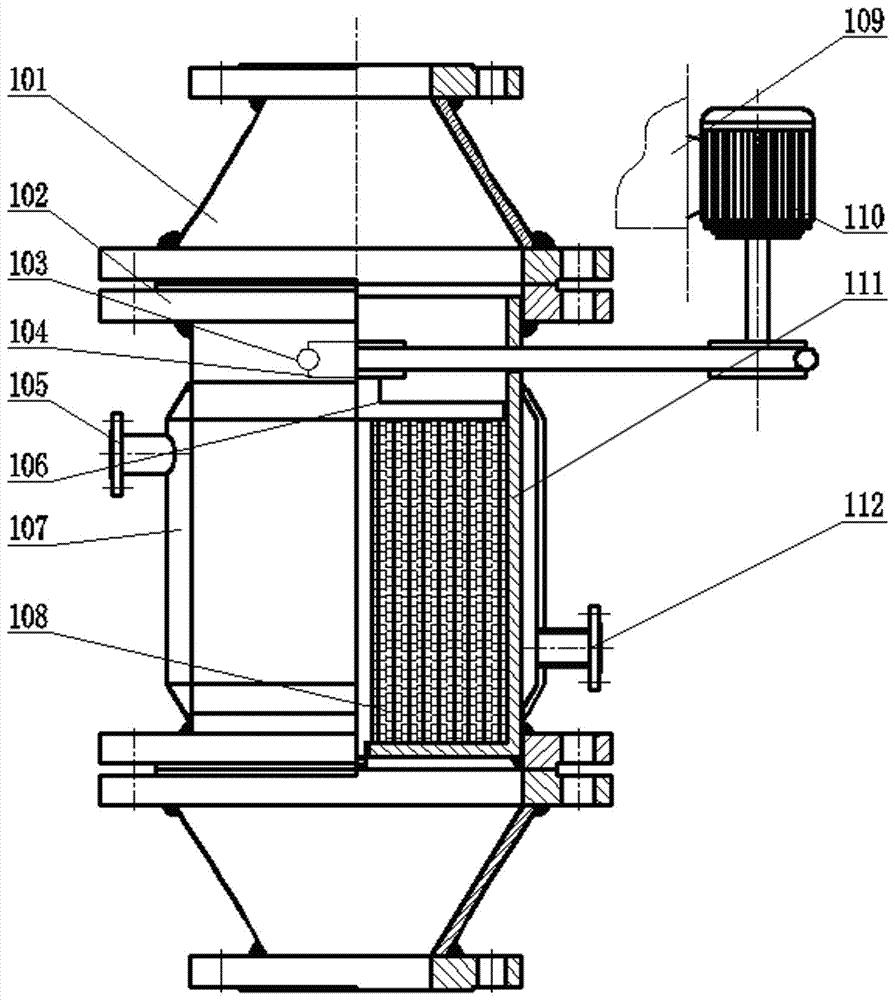

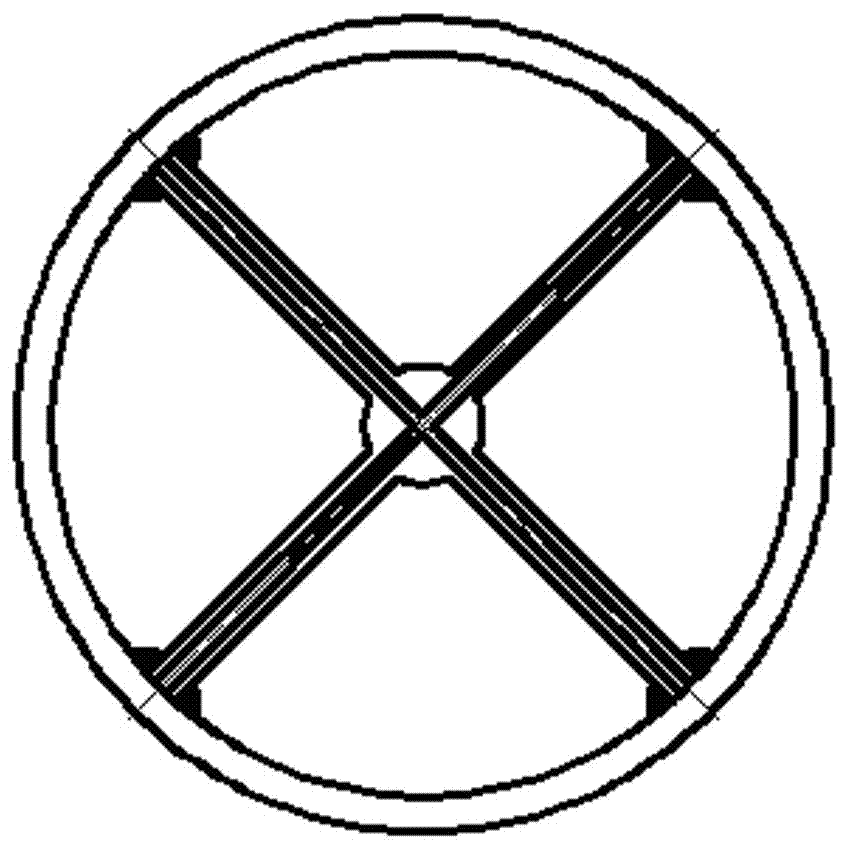

[0027] As shown in the figure, the jacketed multi-circuit naphthalene forced crystallization recovery device includes a multi-layer screen cylinder 108, grid plate 106, cylinder body 111, jacket 107, variable diameter flange 101, O-belt, pulley 104, roller Needle bearing and deceleration motor 110, the bottom of the cylinder 111 is welded with a cross support structure, a round hole is opened in the middle of the bottom of the cylinder 111, and a needle roller bearing is installed in the round hole, and the shaft 402 in the middle of the grid plate 106 is installed in the needle roller bearing , the grid plate 106 and the multi-layer screen cylinder 108 are set together to form a multi-circuit structure, and the needle roller bearing plays the role of axial positioning and support for the grid plate 106; During the rotation of the brush with the grid plate 106, the crystallized naphthalene on the multi-layer screen cylinder is scraped off and dropped back to the naphthalene sto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com