Wastewater treatment method and wastewater treatment system

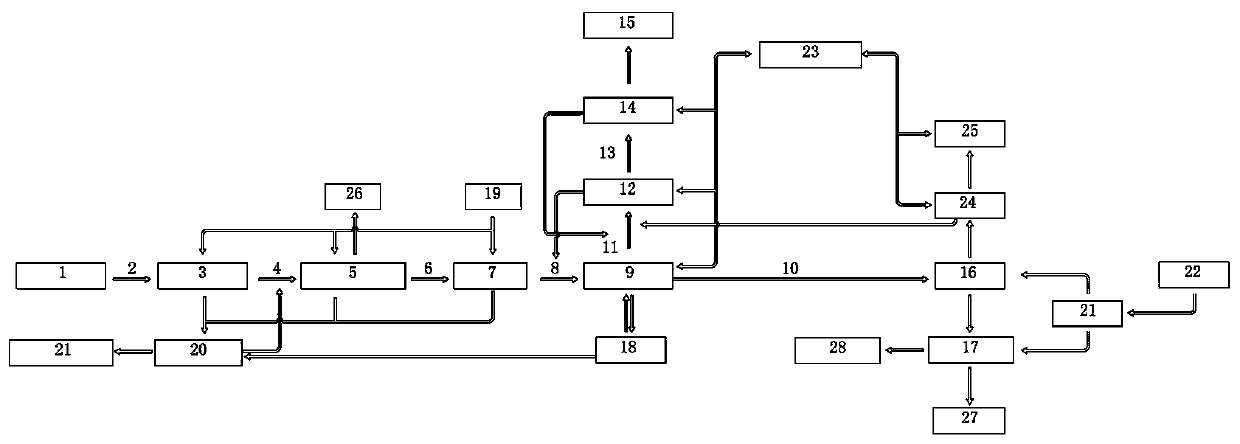

A wastewater treatment system and technology for wastewater treatment, applied in multi-stage water treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of inability to completely deal with heavy metal pollution, pollution still exists, etc., to reduce secondary pollution , Not easy to block the pipeline, the effect of high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

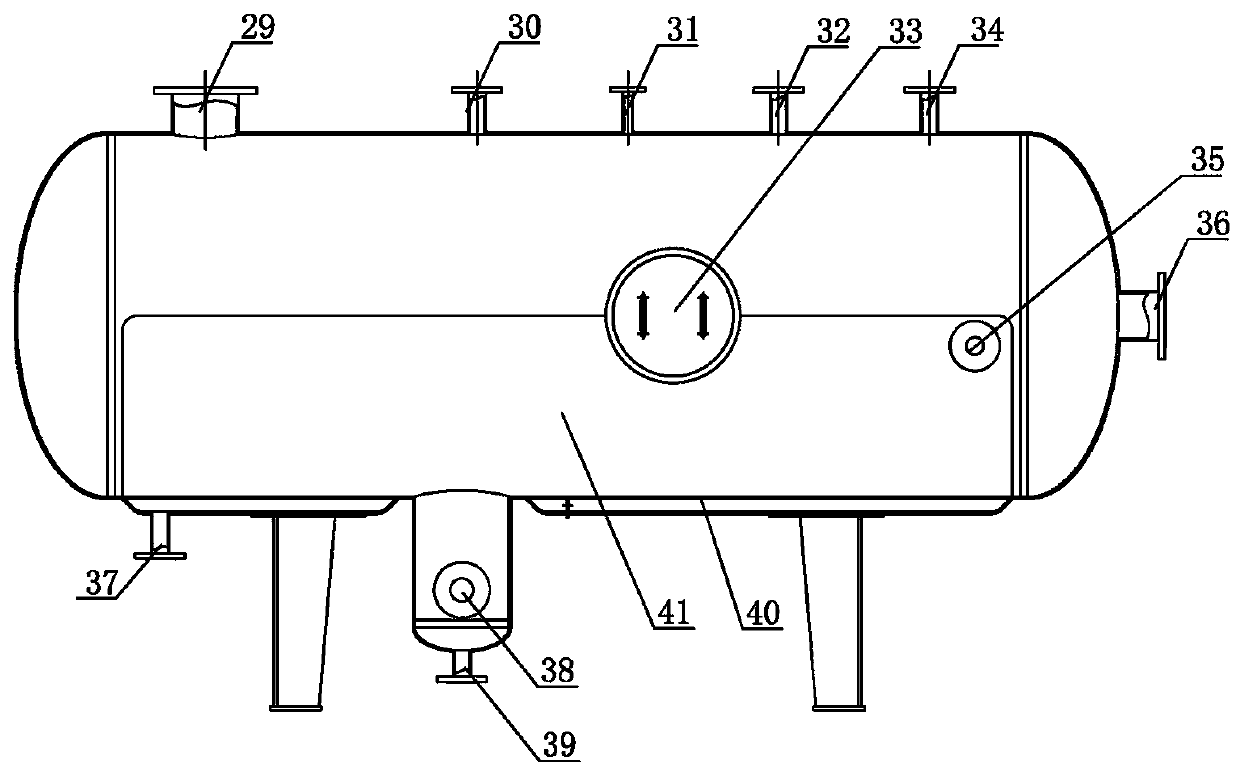

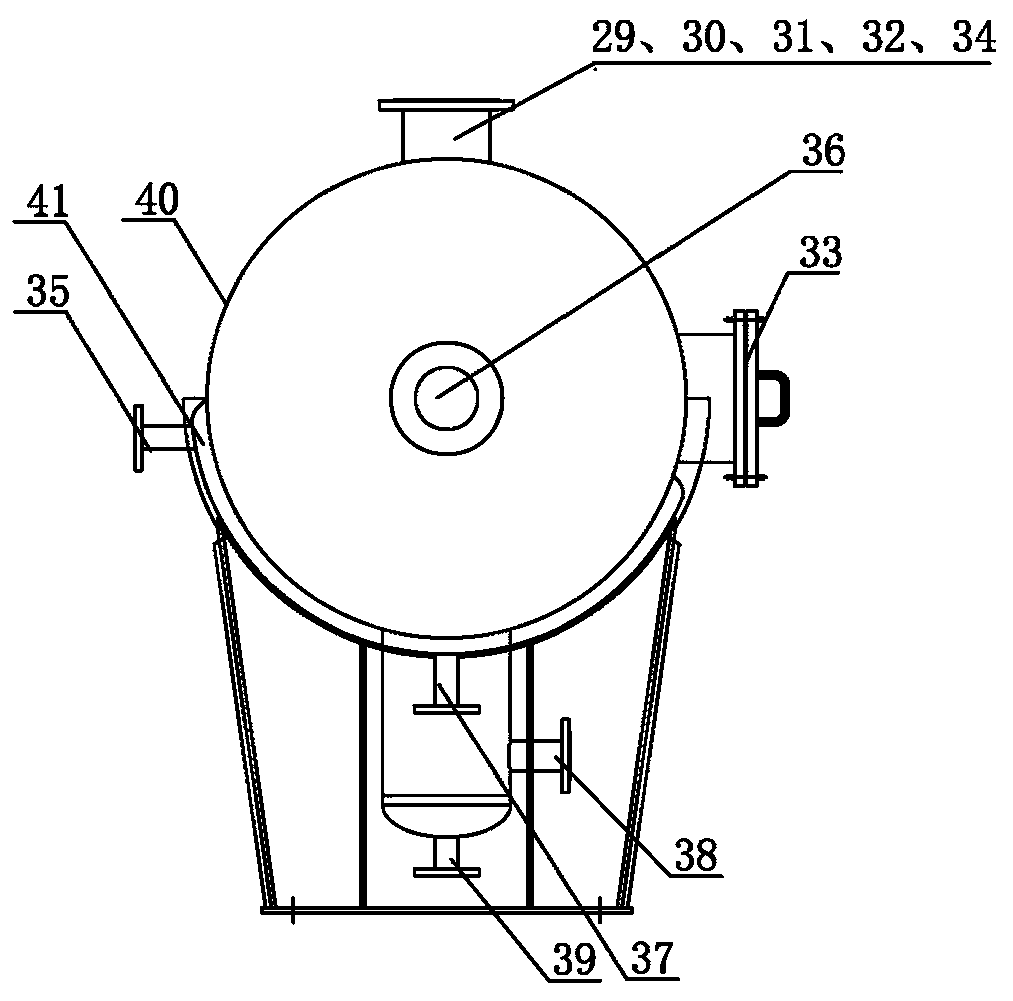

[0057]1. When the treated wastewater is chromium-containing wastewater, the solid content in the filtrate after the RO membrane step is about 5%, and enters the first concentrated liquid relay tank 10, and 150 kg of the first concentrated liquid relay tank 10 The concentrated liquid enters the tank body 40 of the evaporator. At this time, the inside of the tank body 40 is not evacuated. The hot oil enters the heating jacket 41 from the heating medium inlet 37 and leaves from the heating medium outlet 35. The hot oil circulates to heat the tank body 40. When the thermometer at the thermometer port 30 detects that the temperature in the tank 40 is 60 degrees, stop heating, and the tank 40 starts to vacuumize, and the vacuum degree is -0.094 MPa until the water starts to boil, and about 65 kg of water evaporates after 2-3 minutes .

[0058] 2. Then add 50 kg of concentrated liquid from the first concentrated liquid relay tank 10. During the process of adding liquid, part of the v...

Embodiment 2

[0065] 1. When the waste water treated is nickel-containing waste water, the solid content in the filtrate after the RO membrane step is about 5%, and enters the first concentrated liquid relay tank 10, 150 kg of the first concentrated liquid relay tank 10 The concentrated liquid enters the tank body 40 of the evaporator. At this time, the inside of the tank body 40 is not evacuated. The hot oil enters the heating jacket 41 from the heating medium inlet 37 and leaves from the heating medium outlet 35. The hot oil circulates to heat the tank body 40. When the thermometer at the thermometer port 30 detects that the temperature in the tank 40 is 55 degrees, stop heating, and the tank 40 starts vacuuming, and the vacuum degree is -0.094 MPa until the water starts to boil, and about 70 kg of water evaporates after 6-7 minutes .

[0066] 2. Then add 50 kg of concentrated liquid from the first concentrated liquid relay tank 10, the heating jacket 41 heats the liquid to 58 degrees, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com