A closed circulation process system and method for sodium chlorate crystallization evaporation water

A circulating system, sodium chlorate technology, applied in chloric acid, evaporation, chlorate and other directions, can solve problems such as environmental pollution, save energy, reduce material consumption, and improve the effect of vacuum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

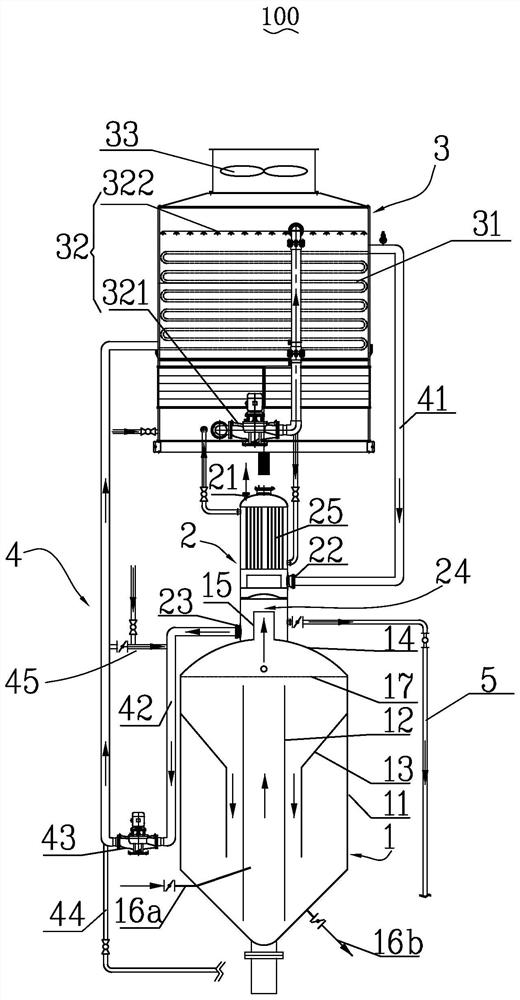

[0037] attached figure 1 It is a structural schematic diagram of the sodium chlorate crystallization evaporation water closed circulation process system provided by the invention. The sodium chlorate crystallization evaporation water closed circulation process system 100 of the present invention includes an evaporation crystallizer 1, an atmospheric condensate gas 2, a closed cooling water tower 3, a process circulating water pipeline 4 and an overflow pipe 5.

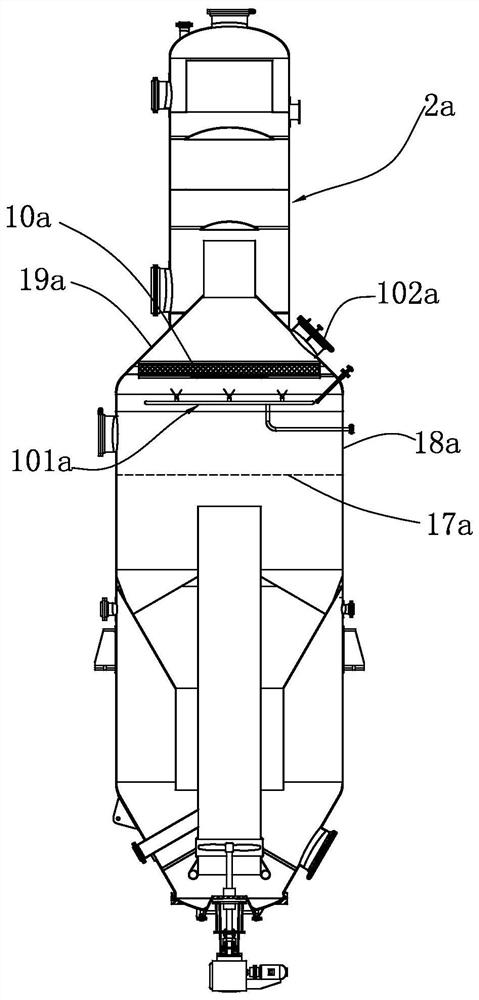

[0038] The evaporation crystallizer 1 includes a cylinder 11, a feed part 12 vertically arranged in the center of the cylinder 11, a funnel-shaped discharge part 13 sleeved outside the feed part 12, and an elliptical head arranged on the top of the cylinder 14. The gas riser 15 located at the top of the oval head 14 . Wherein the feeding part 12 is a straight cylinder, and the liquid flow direction in it is from bottom to top; The feeding part 12 is connected with the feeding pipe 16a, and the sodium chlorate electrol...

Embodiment 2

[0051] Based on the sodium chlorate crystallization evaporation water closed circulation process system of embodiment 1, the sodium chlorate crystallization evaporation water closed circulation process method provided by the invention comprises the steps:

[0052] (1) Supplement cooling water once to the closed cooling water tower to ensure its continuous evaporation of water and maintain heat removal capacity; supplement process soft water to the system through the process soft water inlet pipe until water flow appears at the overflow port of the atmospheric condenser;

[0053] (2) the sodium chlorate electrolytic solution after the preheating enters the feeding part 12 of evaporative crystallizer 1 center, opens the vacuum pump system that is connected with atmospheric condenser non-condensable gas outlet pipe 21, provides vacuum for the initial evaporation of evaporative crystallizer, When the vacuum reaches 90-93KPa, the boiling point of water vapor is 44-46°C, and the wate...

specific Embodiment approach

[0062] By the specific embodiment of the present invention and the processing method of prior art, compare in detail, the sodium chlorate crystallization evaporation water closed loop processing method provided by the present invention and improvement advantage, with the output of 50,000 tons of sodium chlorate / year, The specific implementation is as follows:

[0063] (1) Closed cooling water tower operates independently: when the external temperature is 20°C, before the operation of the crystallization evaporator, the closed cooling water tower is supplemented with industrial water through the replenishment valve, which is used as the cooling circulating water of the closed cooling water tower. After replenishing the water, it operates independently, rated Circulating water volume 900m 3 / h, the head of the cooling water circulation pump is 15 meters, and the motor power is 63kw. The stable operation of the cooling tower ensures the heat removal capacity of the system. The wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com