Safety control method of storage tank VOCs discharging open flame equipment

A technology for safety control and storage tanks, applied in fire rescue, containers, packaging, etc., can solve the problems that the gas phase space of storage tanks is easy to form an explosive environment, and open flame equipment is prone to flash explosion, etc., to reduce the risk of fire, prevent flash explosion, The effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

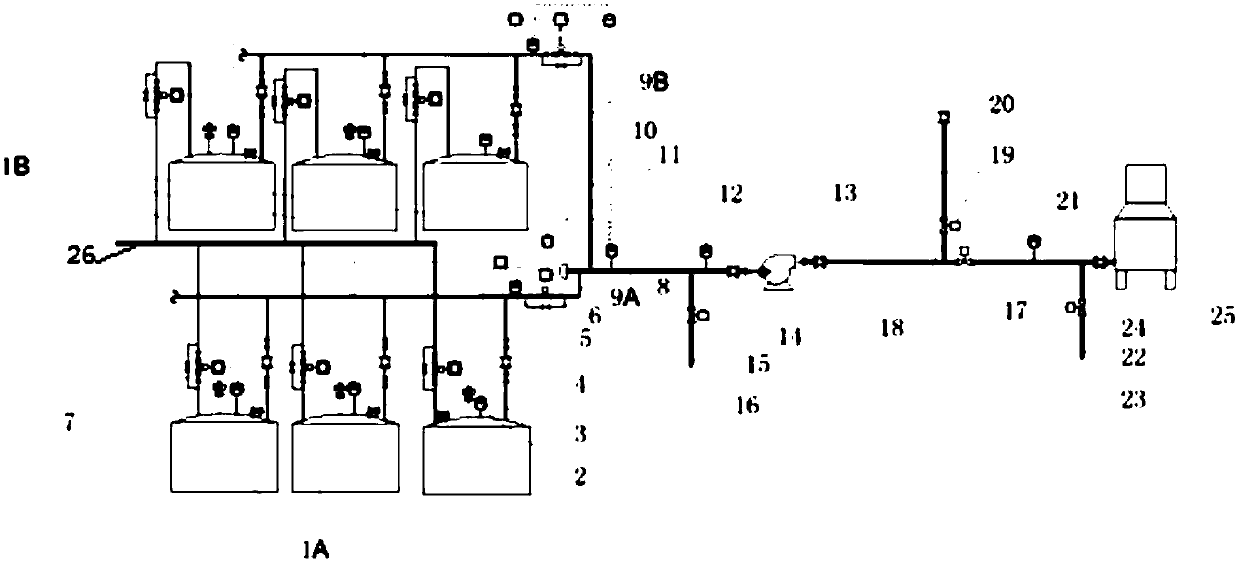

[0051] like figure 1 , a safety control method for storage tank VOCs emission open flame equipment, comprising the following steps:

[0052] Classified collection of VOCs in storage tank groups of various materials: the VOCs emitted by storage tank groups 1A / B of various materials are classified and collected through the oil and gas branch pipe 3 filled with each storage tank.

[0053] VOCs connection treatment of storage tanks of the same or similar materials: the VOCs discharged from multiple storage tanks 1A of the same or similar materials in multiple oil and gas branch pipes 3 collected by classification are collected into the same or similar oil and gas tank group oil and gas collection pipe 9A Connecting processing is carried out in the oil and gas branch pipe 3 collected by classification, and the VOCs discharged from the storage tank group 1B of the same or similar material in the multiple oil and gas branch pipes 3 collected by classification are collected in the tan...

Embodiment 2

[0081] According to the method of embodiment 1, the difference is: only there is no nitrogen purging measure for safety control of open flame equipment. The method in Example 2 not only realizes the VOCs treatment of various material storage tanks, but also effectively reduces the emission of VOCs, and at the same time greatly reduces the risk of fire in the storage tanks and prevents flash explosion accidents of open flame equipment.

Embodiment 3

[0083] According to the method of embodiment 1, the difference is: only there is no oxygen content measure treatment of oil and gas main pipeline safety control. The method of Example 3 not only realizes the VOCs treatment of various material storage tanks, but also effectively reduces the emission of VOCs, and at the same time reduces the risk of fire in the storage tanks and prevents flash explosion accidents of open flame equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com