storage tank vocs safe collection zero discharge device

A zero-emission, recycling device technology, applied in packaging, transportation and packaging, large containers, etc., can solve the problems of high energy consumption, difficult to meet discharge standards, fire risks in groups of tanks, etc., to achieve efficient recovery, reduce the risk of fire, reduce The effect of emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

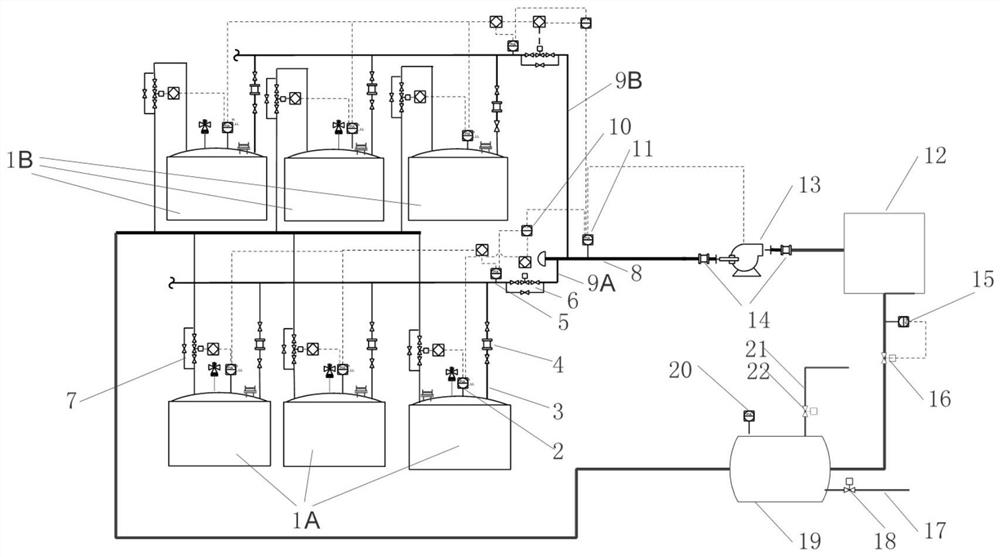

[0048] Such as figure 1 , a zero-emission device for safe collection of VOCs in storage tanks, including two storage tank groups 1A / B of the same or similar materials, a pressurized oil and gas recovery device 12, air extraction equipment 13 and a nitrogen peak-shaving tank 19.

[0049] The roof of each storage tank in the storage tank group 1A / B is respectively provided with a storage tank pressure monitor 2 and an oil and gas branch pipe 3, and the oil and gas branch pipes 3 on the top of multiple storage tanks storing a same or similar material are respectively Connect the oil and gas collecting pipe 9A of the tank group, and the oil and gas collecting pipe 9A of the tank group is connected to the oil and gas main pipe 8 respectively. The oil and gas collecting pipe 9B of the tank group, the oil and gas collecting pipe 9B of the tank group is connected to the oil and gas main pipe 8 respectively, so that the gas phase spaces of multiple storage tanks storing the same or sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com