Pull-in type cable explosion-proof box

An explosion-proof box, pull-in technology, applied in the direction of cable joints, cable inlet sealing devices, etc., can solve the problems of cable insulation and drop cable breakdown, cable water and moisture, etc., to achieve reliable design principles, prevent water ingress, and meet waterproof requirements Anti-explosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

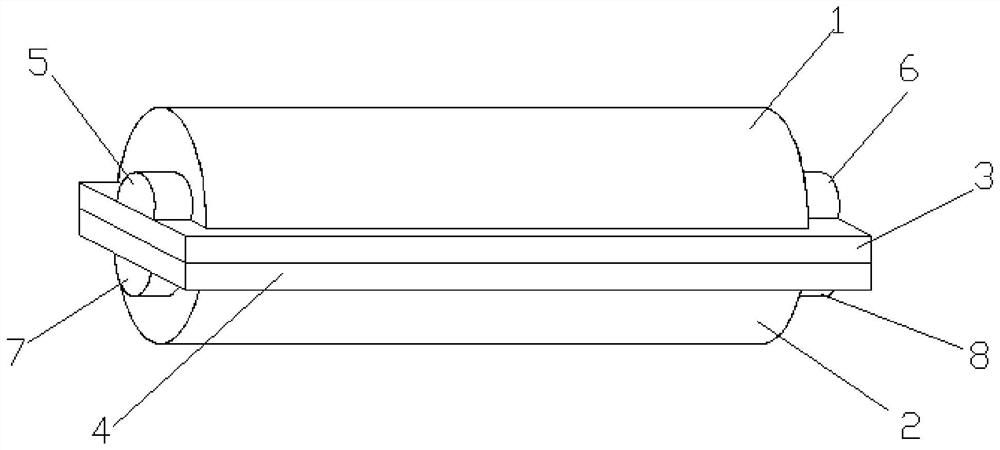

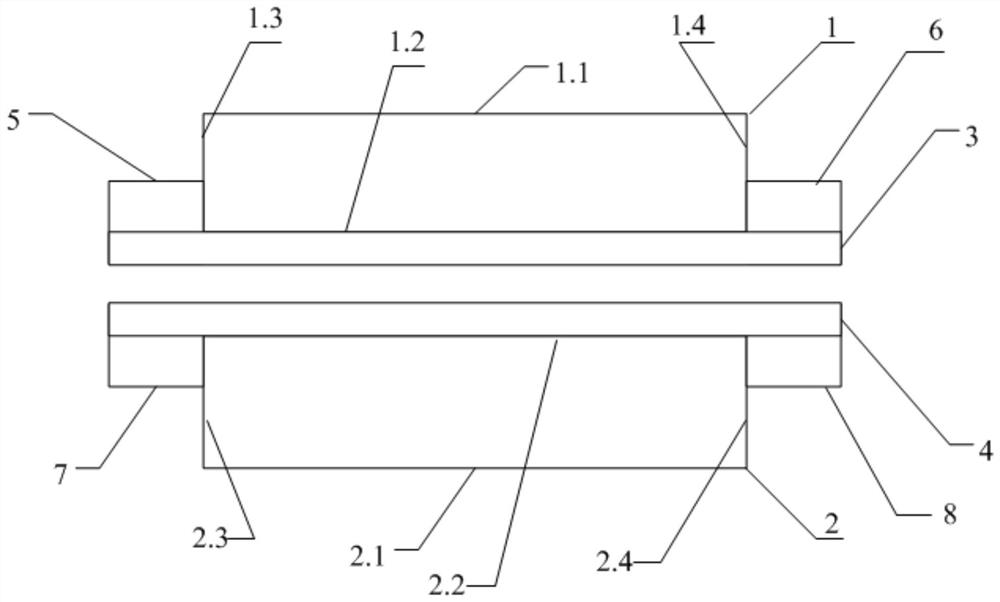

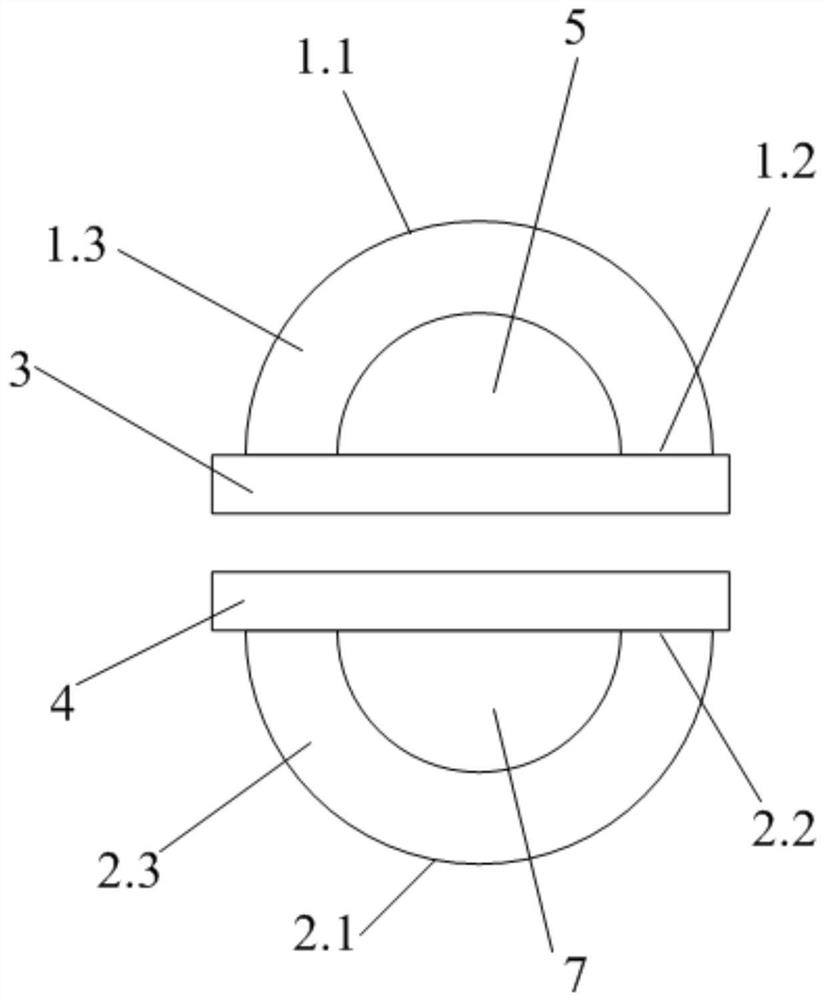

[0047] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides a suction-type cable explosion-proof box, comprising an upper explosion-proof shell 1 and a lower explosion-proof shell 2;

[0048] Both the upper explosion-proof shell 1 and the lower explosion-proof shell 2 are made of flexible waterproof material;

[0049] The upper explosion-proof shell 1 includes an upper arc explosion-proof surface 1.1, an upper rectangular fitting surface 1.2, a first upper semicircular end surface 1.3 and a second upper semicircular end surface 1.4; the first upper semicircular end surface 1.3 and the second upper semicircular end surface 1.4 are arranged on the upper arc The two ends of the rectangular explosion-proof surface 1.1 are connected to the upper rectangular fitting surface 1.2 to form a solid semi-cylindrical upper explosion-proof shell;

[0050] The lower explosion-proof shell 2 includes a lower arc-shaped explosion-proof surface 2.1, ...

Embodiment 2

[0056] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention provides a suction-type cable explosion-proof box, an upper explosion-proof shell 1 and a lower explosion-proof shell 2;

[0057] The upper explosion-proof shell 1 and the lower explosion-proof shell 2 are made of flexible waterproof material; the upper explosion-proof shell 1 and the lower explosion-proof shell 2 are made of hydrophobic silicone material;

[0058] The upper explosion-proof shell 1 includes an upper arc explosion-proof surface 1.1, an upper rectangular fitting surface 1.2, a first upper semicircular end surface 1.3 and a second upper semicircular end surface 1.4; the first upper semicircular end surface 1.3 and the second upper semicircular end surface 1.4 are arranged on the upper arc The two ends of the rectangular explosion-proof surface 1.1 are connected to the upper rectangular fitting surface 1.2 to form a solid semi-cylindrical upper explosion-proof shell;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com