Flame monitoring technology optimization method for improving safety of combustion furnace

A technology of flame monitoring and optimization method, which is applied in the direction of combustion method, safety device of combustion chamber, combustion chamber, etc., can solve problems such as not being able to effectively avoid dangerous accidents, and achieve good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

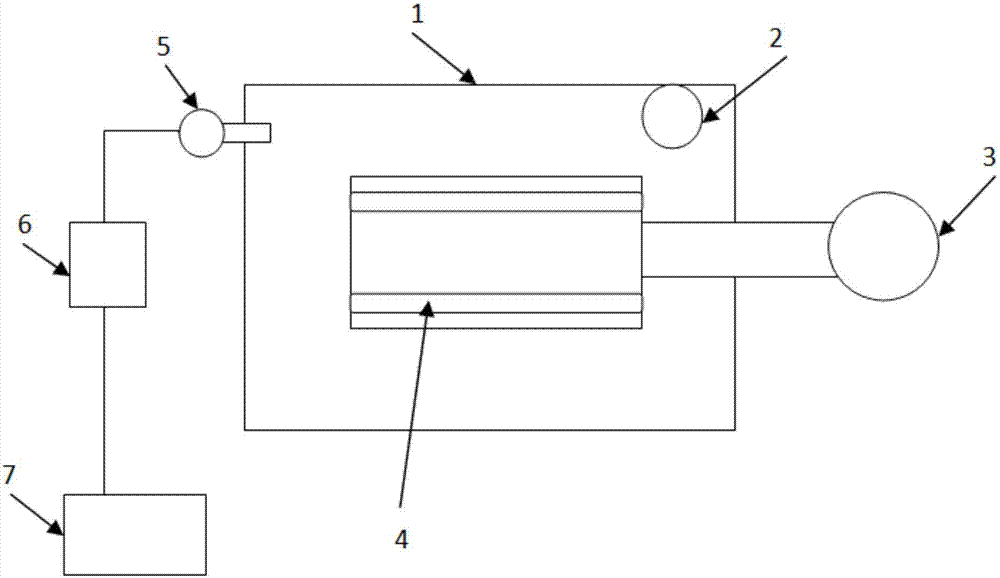

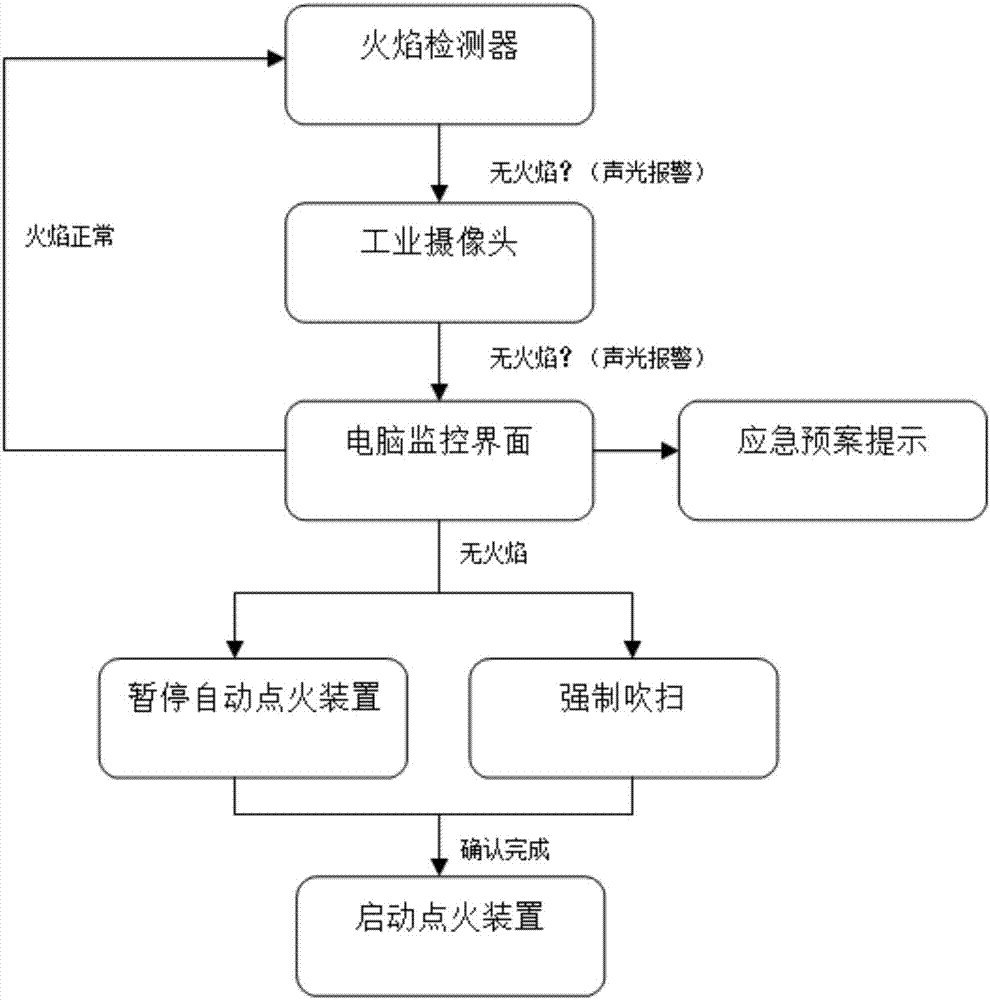

[0020] Taking the combustion furnace in a certain petrochemical plant as an example, the present invention will be described in detail in conjunction with the accompanying drawings. In order to ensure the safe operation of the combustion furnace, the production unit has set up multiple safety measures for the combustion furnace, among which setting a flame monitoring system in the combustion furnace is one of the important protection measures. In this embodiment, a flame detector and an industrial camera are provided on the furnace body of the combustion furnace. By setting the linkage of the flame detector and the industrial camera, the detection is carried out through two monitoring methods with different principles. At the same time, sound and light alarm systems are set up to remind operators to process in real time through the monitoring interface, thereby improving the safety of the combustion furnace. Specifically, this embodiment provides an optimization scheme for a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com