Active safety detection method for dry cleaning machine

An active safety and detection method technology, applied in dry cleaning equipment, washing equipment, textiles and papermaking, etc., can solve problems such as high concentration of dry cleaning solvents, flash explosions, etc., and achieve the effect of avoiding flash explosions and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

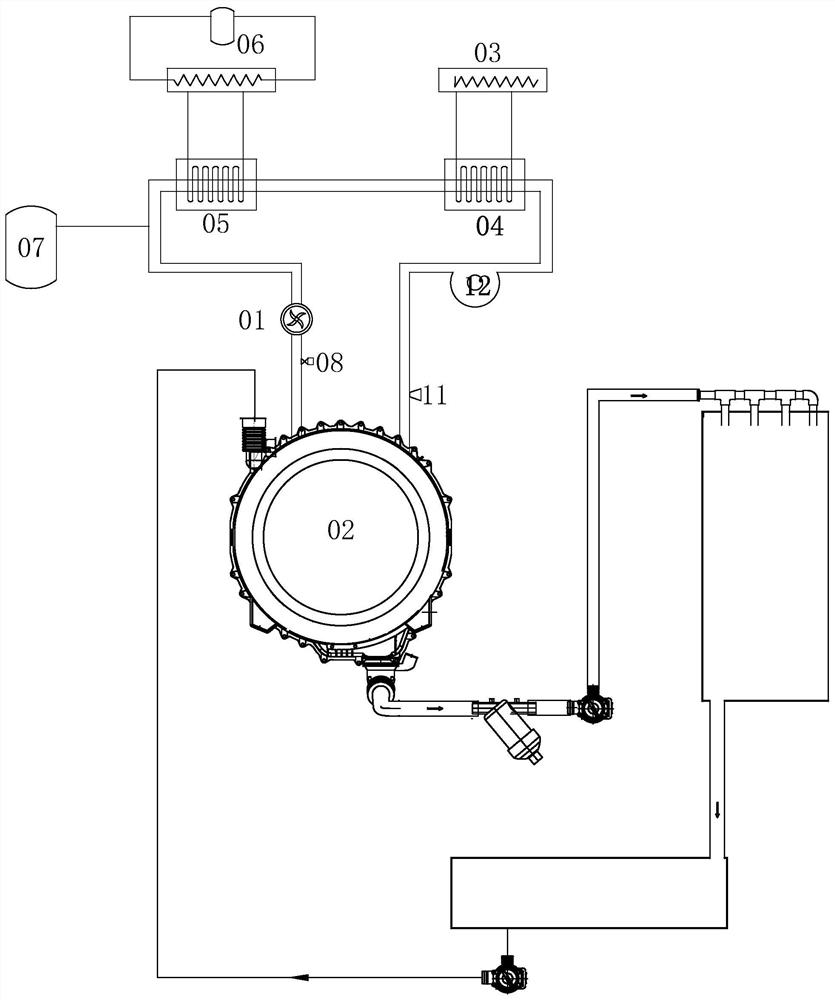

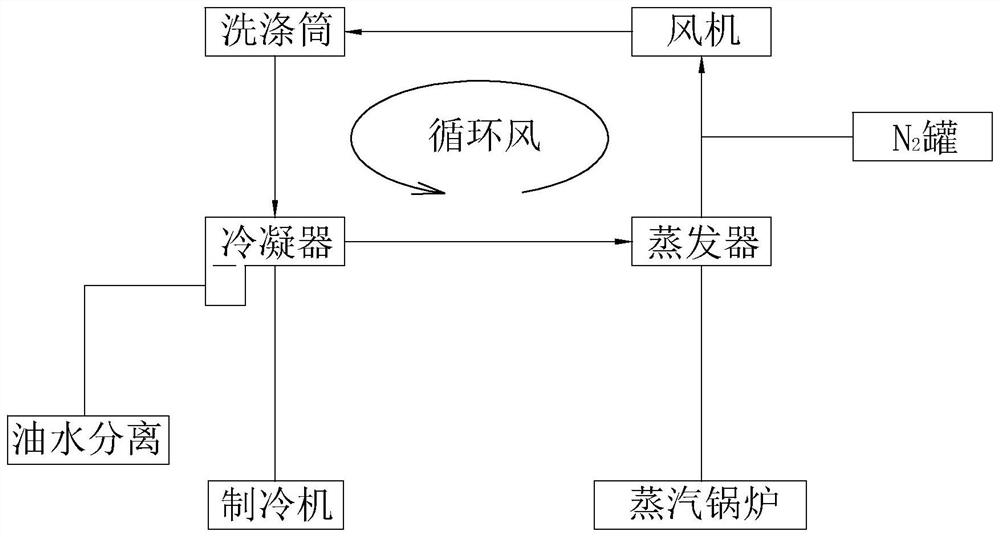

[0030] figure 1 , figure 2 It is the working flow chart of the present invention. After the clothes are washed, the centrifugal fan 01 is started to circulate the air in the washing drum 02 and the drying circulation air duct. After the refrigerator 03 is started, the temperature of the low-temperature coil of the condenser 04 is reduced. The humid air from the washing drum 02 is condensed here, and the mixture of water and dry cleaning solvent obtained by the condensation is captured by the drain channel under the condenser and then discharged, and the dried air continues backward through the subsequent evaporator 05 , the evaporator 05 is heated by the steam boiler 06, the air is heated to form hot air, the hot air is hot dry air, and the hot air continues to pass through the centrifugal fan 01 and then enters the washing tub to dry the clothes. During the cycle, the laundry is dried.

[0031] The technical problem in the prior art is that in the drying process, the mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com