A kind of preparation method of small particle size doped potassium-molybdenum alloy powder

A molybdenum alloy and small particle size technology, which is applied in the field of preparation of small particle size potassium-molybdenum alloy powder, can solve the problems of long reduction time, high reduction temperature, and large particle size of potassium-molybdenum alloy powder, so as to avoid hydrogen flash explosion and process Simple, narrow particle size distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

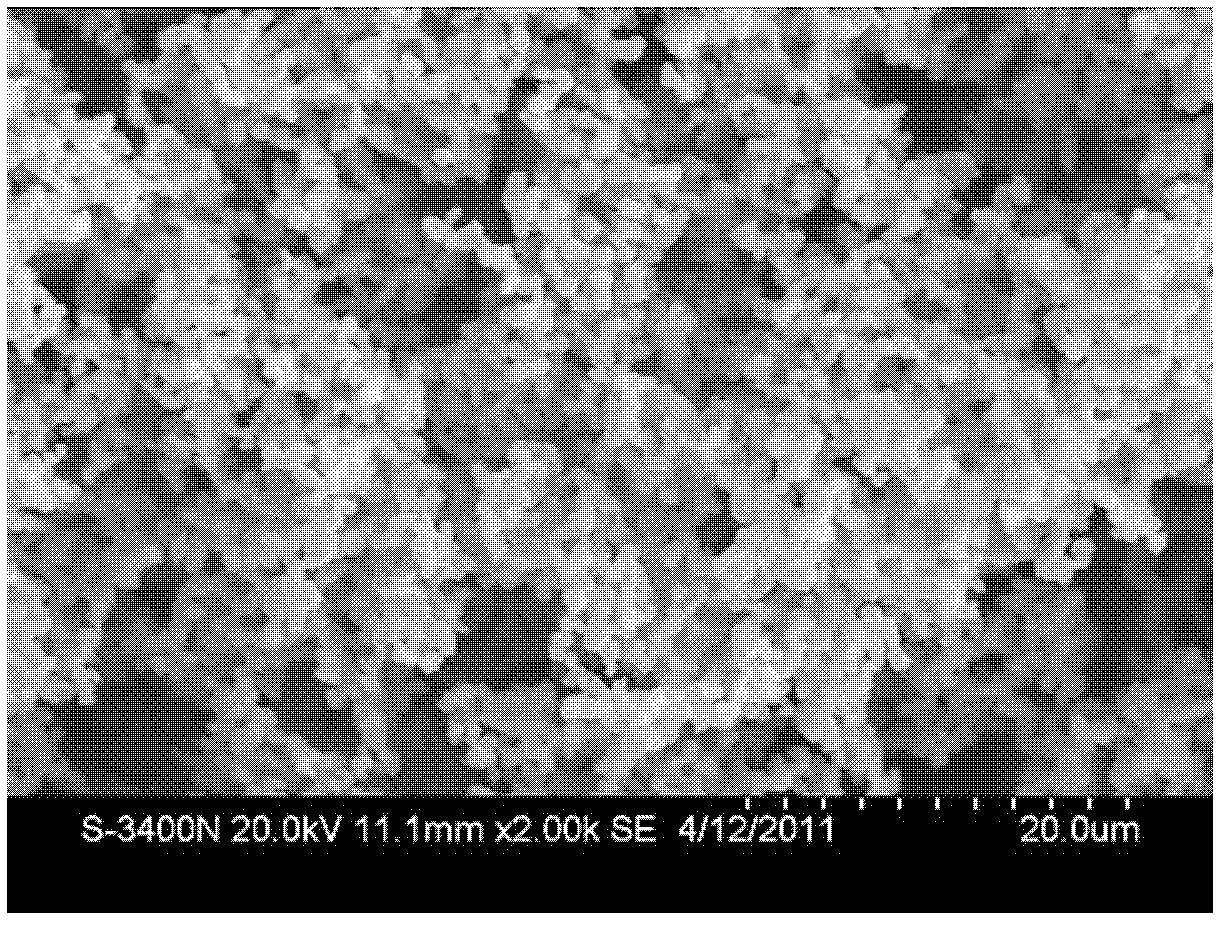

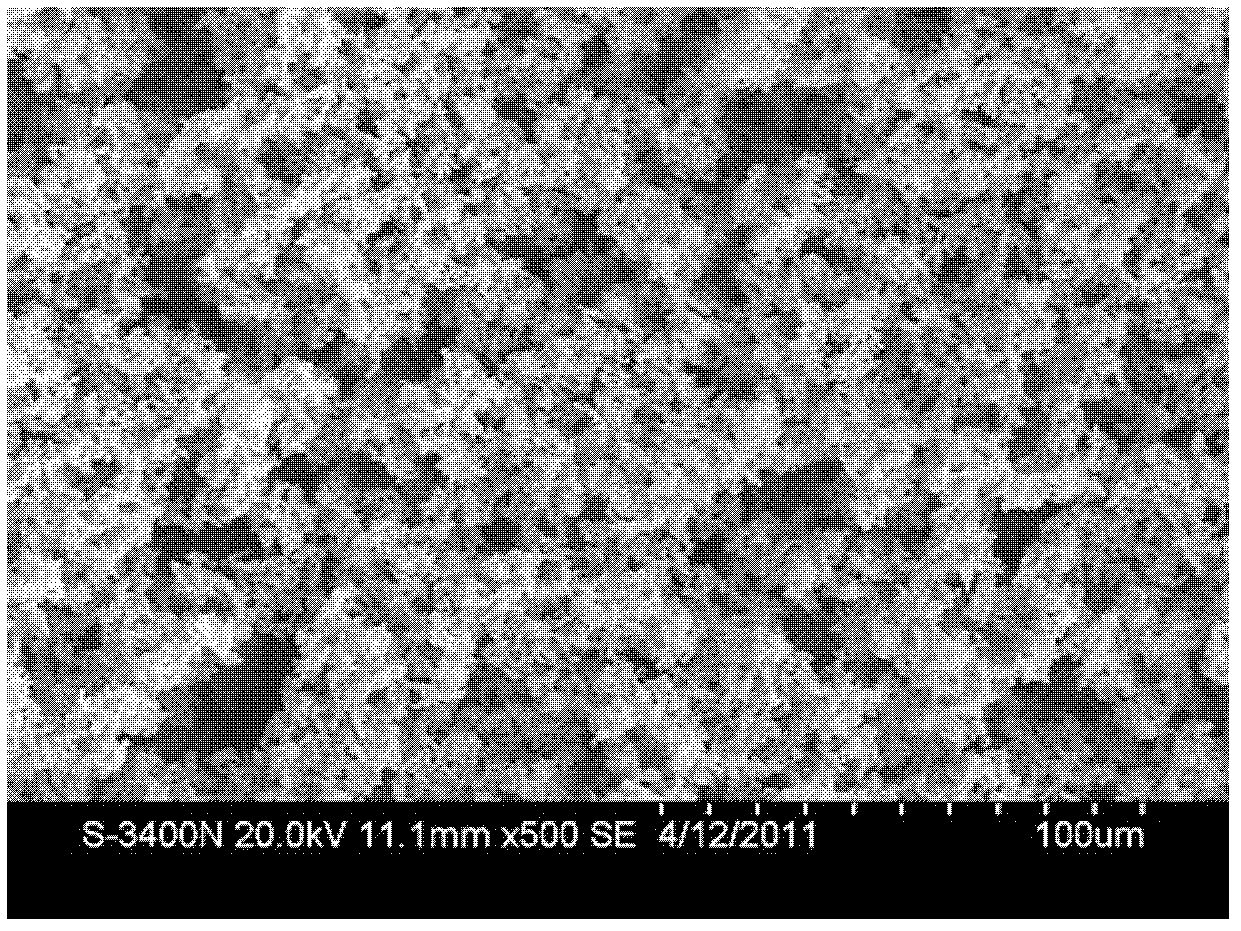

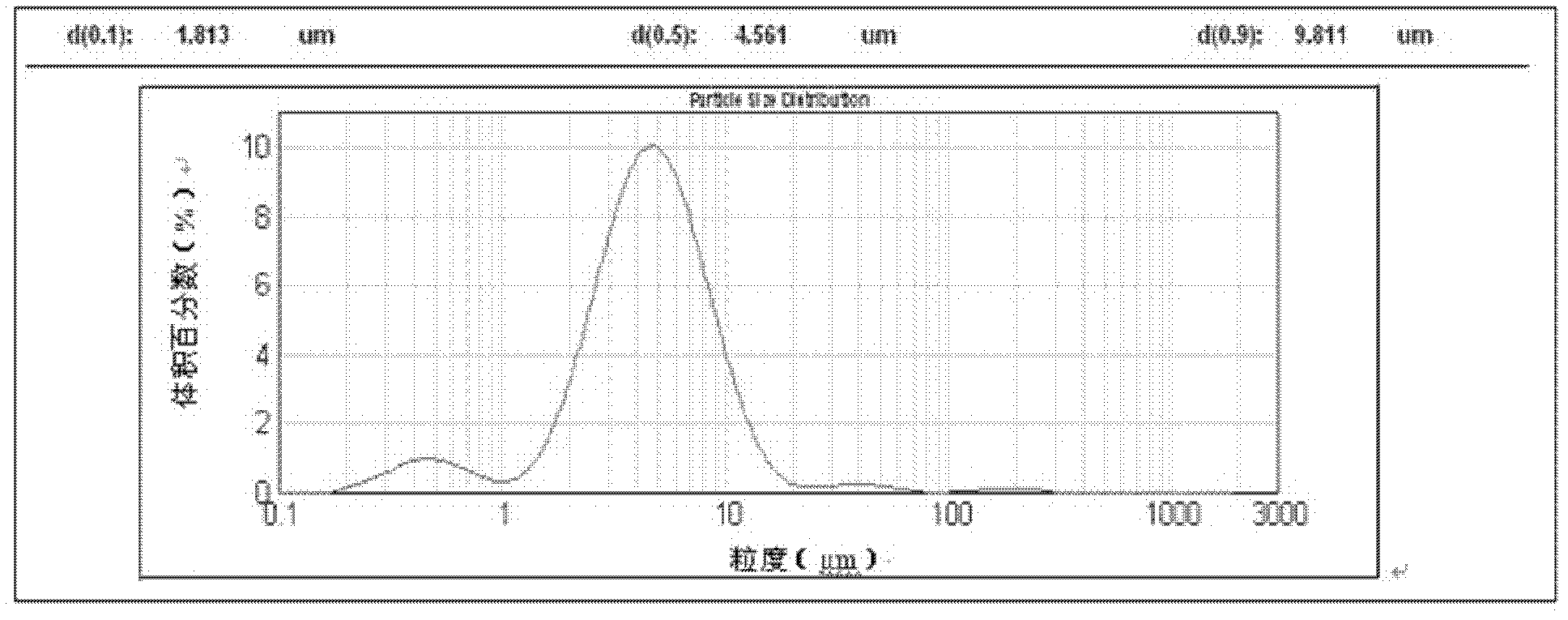

Embodiment 1

[0028] The molybdenum dioxide alloy powder with a potassium mass percentage content of 0.08% is used as a raw material, passes through a 200-mesh sieve, and takes the sieve material as a reduction raw material and places it in a conventional single-temperature zone reduction furnace (during the preparation process, the single-temperature zone reduction furnace The furnace mouth is open to remove the moisture in the furnace chamber of the reduction furnace as soon as possible, and ignite at the furnace mouth to prevent hydrogen from flashing), the loading capacity of the boat is 1.2kg / boat, and the hydrogen flow rate is 14m 3 / h, the temperature is 940 ° C under constant temperature conditions for 5.5h reduction treatment, after cooling with the furnace to obtain potassium-molybdenum alloy powder with an average particle size of 1.5 μm, the mass percentage of potassium in the potassium-doped molybdenum alloy powder is 0.1% .

[0029] The potassium-molybdenum alloy powder that h...

Embodiment 2

[0032] Adopt the molybdenum dioxide alloy powder that potassium mass percentage content is 0.25% as raw material, pass through 200 mesh sieves, take the sieve material and place it in the conventional single temperature zone reduction furnace as the reduction raw material (during the preparation process, the single temperature zone reduction furnace The furnace mouth is open to remove the moisture in the furnace chamber of the reduction furnace as soon as possible, and ignite at the furnace mouth to prevent hydrogen from flashing), the loading capacity of the boat is 1.2kg / boat, and the hydrogen flow rate is 12m 3 / h, the temperature is 950 ° C under constant temperature conditions for 4.5 hours of reduction treatment, after cooling with the furnace, potassium-molybdenum alloy powder with an average particle size of 2.5 μm is obtained, and the mass percentage of potassium in the potassium-molybdenum alloy powder is 0.3%. .

[0033] The potassium-molybdenum alloy powder that ha...

Embodiment 3

[0036]Adopt the molybdenum dioxide alloy powder that potassium mass percentage content is 0.4% as raw material, cross 200 mesh sieves, get the material on the sieve and place it in the conventional single temperature zone reduction furnace as the reduction raw material (during the preparation process, the single temperature zone reduction furnace The furnace mouth is open to remove the moisture in the furnace chamber of the reduction furnace as soon as possible, and ignite at the furnace mouth to prevent hydrogen from flashing), the loading capacity of the boat is 1.2kg / boat, and the hydrogen flow rate is 10m 3 / h, the temperature is 3.5h under constant temperature conditions of 970°C, and after cooling with the furnace, potassium-molybdenum alloy powder with an average particle size of 3.5 μm is obtained, and the mass percentage of potassium in the potassium-molybdenum alloy powder is 0.4%. .

[0037] The potassium-molybdenum alloy powder that has not been screened and batche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com