Extractor hood with high-efficiency trapping function

A range hood, high-efficiency technology, applied in the field of high-efficiency capture range hoods, can solve problems such as closing doors and windows, indoor pollution, side escape of range hoods, etc., to prevent oil fume from escaping, reduce noise and energy Consumption, to avoid the effect of frontal escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

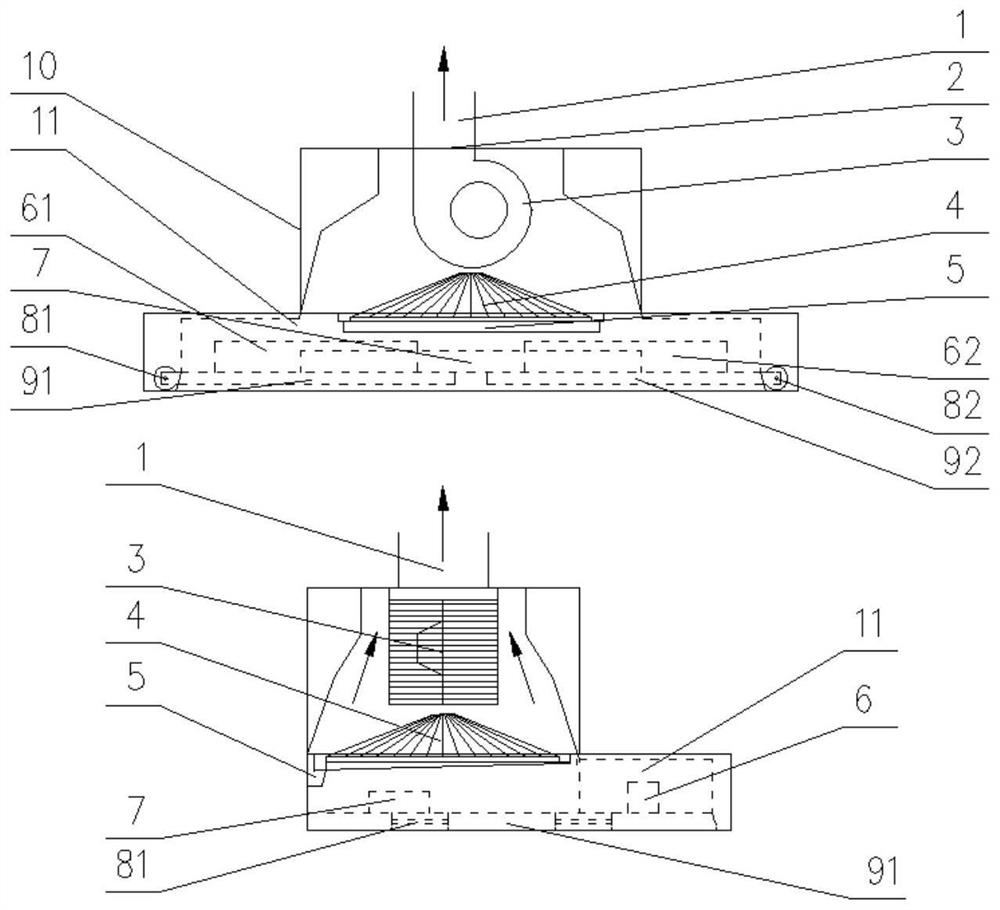

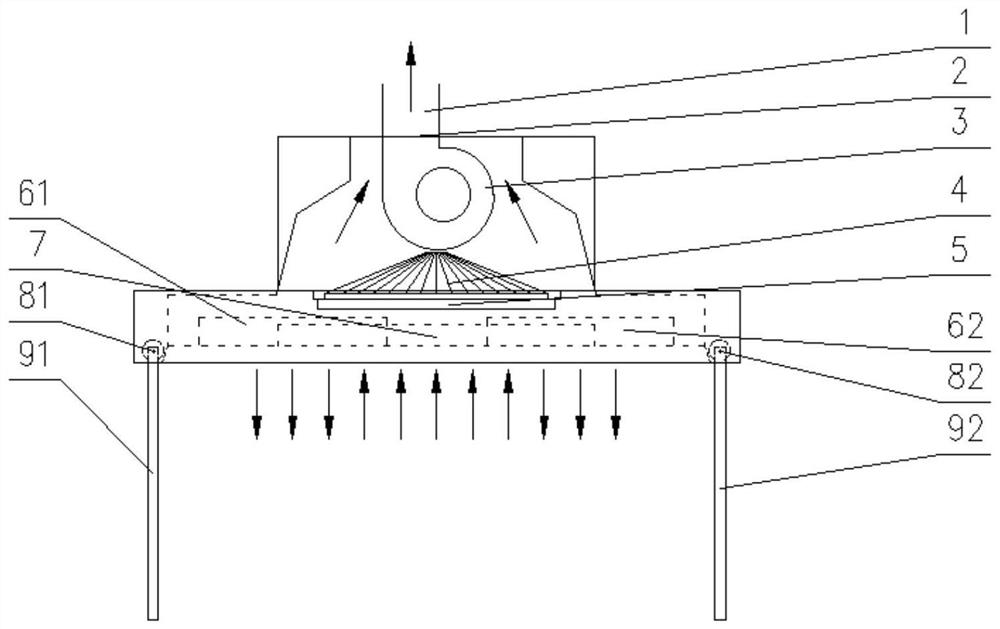

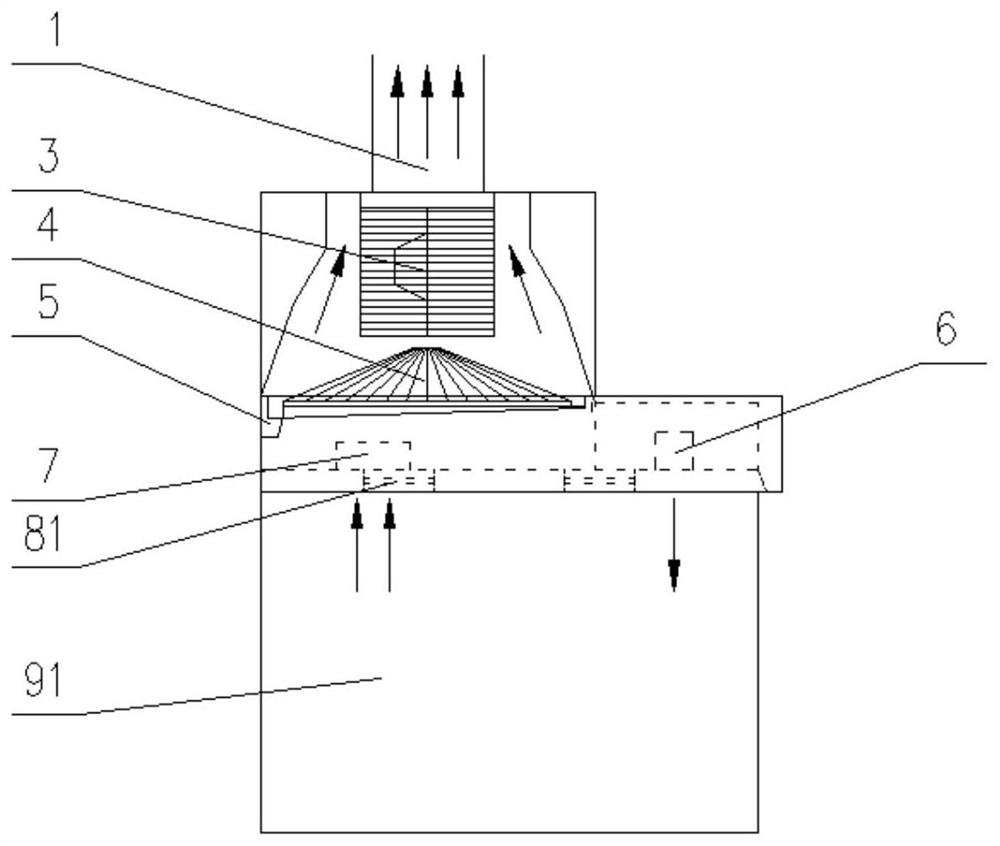

[0018] The present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

[0019] As shown in the accompanying drawings, a high-efficiency collection range hood of the present invention includes a range hood housing 10, an inner shell 11 is installed in the range hood housing 10, and the inner shell 11 Both sides of the shell 11 are provided with supplementary air outlets 61 and 62, which can be driven by a cross-flow fan 6, and an air suction port 7 is provided near the wall of the range hood housing 10; Net 4, oil collecting groove 5, are used for collecting the oil that oil leakage net leaks down. The motor 12 is installed in the range hood housing 10, and the baffle is driven to open and close with the power-on state through the connecting rod 13 and the transmission rods 141 and 142 on both sides, and hinges 81 are respectively installed on both sides of the range hood housing 10. , 82, link to each other with baf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com