S-shaped runner eddy washing spraying chamber

A spraying booth and eddy current technology, applied in the spraying booth, coating, spraying device, etc., can solve the problems of bad influence on yield rate, complicated operation, chaotic airflow distribution and spraying effect, and achieve convenient maintenance and refueling, and reduce exhaust Quantity, the effect of improving the cleaning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

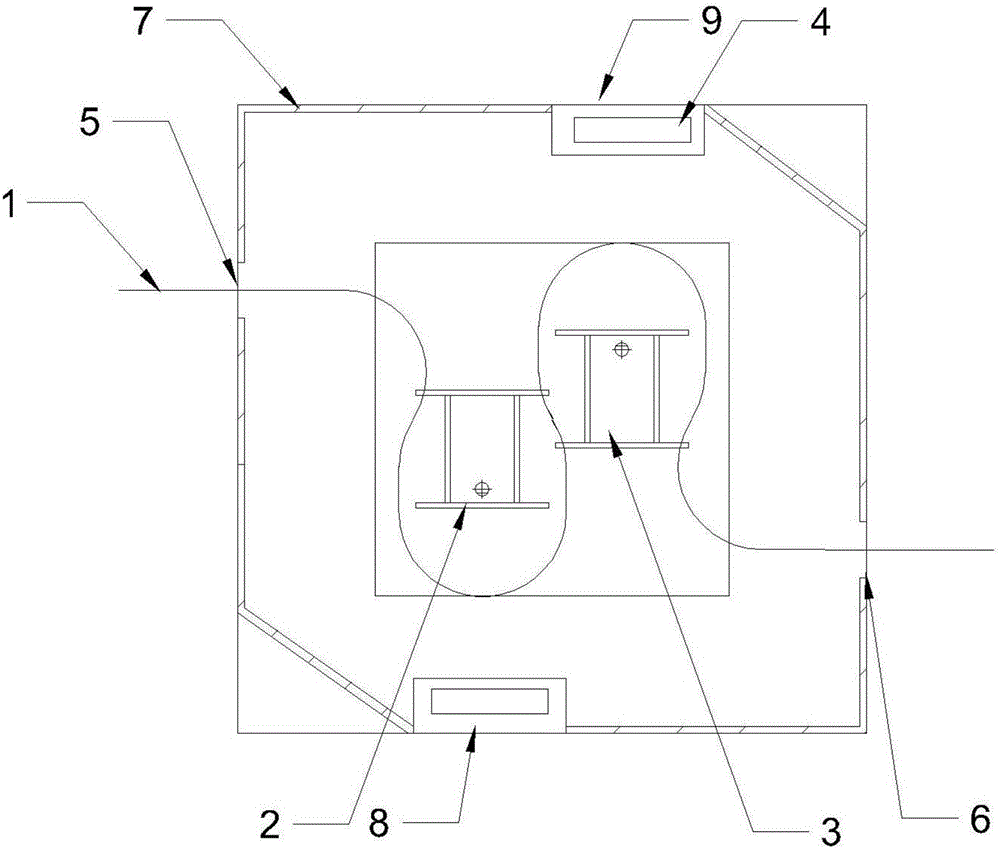

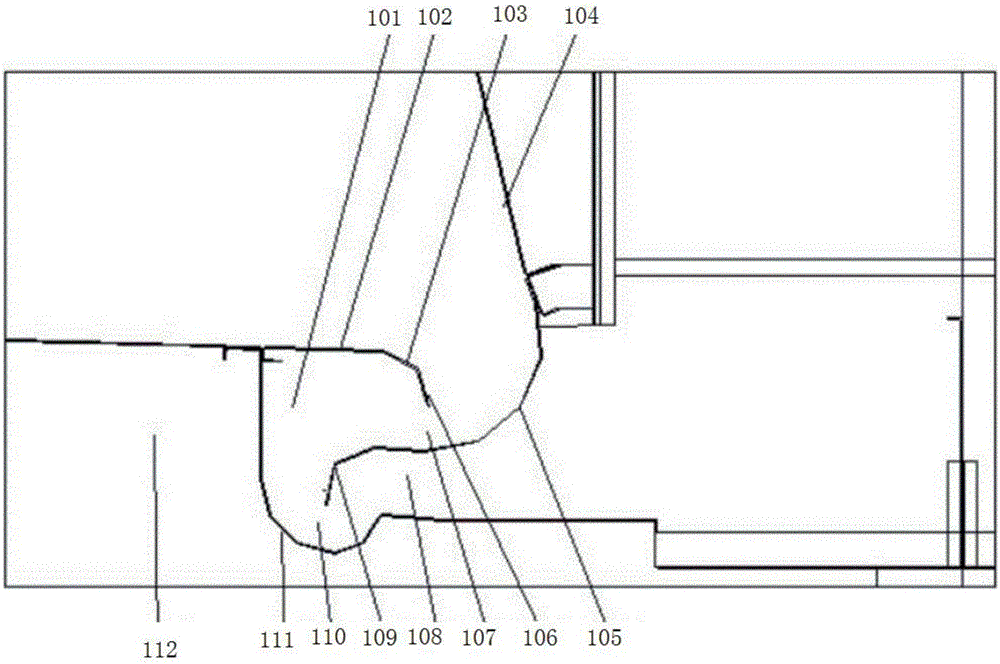

[0015] As shown in the figure, an S-shaped channel vortex washing spray chamber includes a conveying track 1, a first spray gun 2, a second spray gun 3, an S-shaped channel vortex washing device 4, a workpiece inlet 5, and a workpiece outlet 6 , water curtain layer 7, the first exhaust port 8 and the second exhaust port 9, the first spray gun and the second spray gun are staggeredly arranged in the spray chamber, and the workpiece is set on the corresponding spray chamber wall of the first spray gun Inlet, the workpiece outlet is set on the inner wall of the other side of the spraying room corresponding to the second spraying gun, and the conveying track passes through the first spraying gun along the workpiece inlet and rotates once, and then passes through the second spraying gun once to reach the workpiece outlet, forming an S-shaped Track, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com