Safety disposal method and device for exhaust waste gas of petrochemical wastewater treatment plant

A petrochemical sewage and waste gas treatment device technology, which is applied to chemical instruments and methods, separation methods, air quality improvement, etc., can solve the problems that exhaust gas cannot be recovered through condensation, deep condensation consumes a lot of energy, and instrument lags, etc., to achieve long-term guarantee The effects of stable and safe operation, improved safety and reliability, no explosion risk and unsafe hidden danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

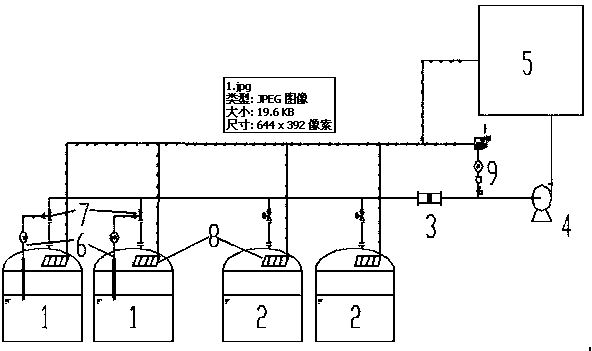

Image

Examples

Embodiment 1

[0028] The sewage treatment plant of a refining and chemical enterprise has structures such as collection wells, lifting tanks, adjustment tanks, grease traps, and flotation tanks for the treatment of oily and salty wastewater. All structures are sealed with covers, and exhaust gas is emitted from each structure through induced draft fans. Introduce a catalytic oxidation device for centralized treatment. On the sealing covers of all structures, there is an automatically adjustable shutter-type gas displacement device. There are oil-water interface meters in the collection wells, lifting tanks, and regulating tanks to monitor the quality of upstream water.

[0029] When light oil enters the water collection well under abnormal conditions, the oil-water detector immediately gives a signal, which is adjusted through the exhaust interlock control valve to reduce the bleed air of the structure by 50%. When the combustible gas concentration monitor detects the exhaust gas and combustib...

Embodiment 2

[0031] The sewage treatment plant of a refining and chemical enterprise has structures such as collection wells, lifting tanks, adjustment tanks, grease traps, and flotation tanks for the treatment of oily and salty wastewater. All structures are sealed with covers, and exhaust gas is emitted from each structure through induced draft fans. Introduce a catalytic oxidation device for centralized treatment. On the sealing covers of all structures, there is an automatically adjustable shutter-type gas displacement device. There are oil-water interface meters in the collection wells, lifting tanks, and regulating tanks to monitor the quality of upstream water.

[0032] When the oil-water detector does not give a signal, and the combustible gas concentration monitor detects that the exhaust gas and combustible gas concentration increases and reaches 20% LEL, the combustible gas concentration monitor sends an alarm signal to start the shutter type gas replacement on the cover of each st...

Embodiment 3

[0034] The sewage treatment plant of a refining and chemical enterprise has structures such as collection wells, lifting tanks, adjustment tanks, grease traps, and flotation tanks for the treatment of oily and salty wastewater. All structures are sealed with covers, and exhaust gas is emitted from each structure through induced draft fans. Introduce a catalytic oxidation device for centralized treatment, install a flame arrestor and a combustible gas concentration monitor in the exhaust gas collection pipeline. Pipeline gas displacement equipment is installed on the sealing covers of all structures, and the gas displacement pipeline is equipped with regulating valves. Oil-water interface meters are installed in the collection wells, lifting tanks, and regulating tanks to monitor the quality of the upstream water. The bleed air outlet pipelines of each structure are equipped with exhaust interlocking control valves.

[0035] When a large amount of light oil enters the collection w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com